What Are Rocker Switches?

Rocker Switches are a type of manual switching device. Rocker switches are used to switch electrical circuits on and off by means of seesaw-like motion buttons.

Rocker Switches are a type of manual switching device. Rocker switches are used to switch electrical circuits on and off by means of seesaw-like motion buttons.

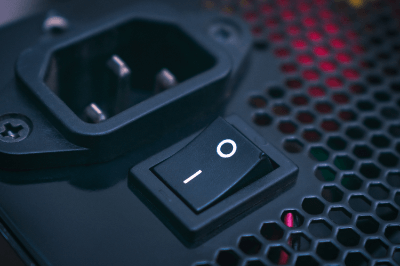

Rocker switches can also be found in the home. For example, they are light switches or power buttons on devices that have a “0” and a “-” on both ends. They are used in a wide variety of equipment and facilities because of their simple construction.

Rocker switches are characterized by the click sound they make when operated, and the fact that they are clearly distinguishable between on and off, which reduces the possibility of accidental operation.

Uses of Rocker Switches

Rocker Switches are widely used as manually operated switches. Most of the switches we see and operate in our daily lives are rocker switches.

Specific examples of rocker switch applications include:

- Switches for lighting in homes and offices power switches for office equipment such as multifunction devices and printers

- Power switches for laboratory equipment and measuring instruments.

Rocker switches are used as operation switches for all kinds of products because of their simple structure and intuitive on/off operation.

However, there are many types of rocker switches. Each switch has different characteristics, such as operating voltage, durability, and water resistance.

Therefore, it is necessary to select the appropriate rocker switch for the intended use and operating environment.

Principle of Rocker Switches

The structure of a rocker switch is simple. The main components of a rocker switch are an operating button that moves like a seesaw, a sealing rubber, a spring, a fixed contact point, a movable contact point, and two connection terminals.

The operating button of the rocker switch is joined to the spring inside. In addition, between the switches operating button and the spring is a sealing rubber. The purpose of the sealing rubber is to protect the contact points from water, dust, and other substances that could affect the operation.

The spring of a rocker switch is bowed. The spring is connected to the operating button and the movable contacts.

When the switch is switched on, the movable contact side of the arched spring moves to press against the fixed contact side, and when the contacts make contact with each other, an electric current flows.

When the rocker switch is switched off, the bow-shaped spring moves so that the movable contact is pulled away from the stationary contact, stopping the flow of current. The advantage of this action is that it prevents the contacts from welding to each other as they are pulled apart.

The terms momentary and alternate are used for push-button switches such as rocker switches. These have different meanings in terms of how the switch moves when pressed.

1. Momentary Rocker Switch

Momentary Rocker Switches switch the electrical circuit only as long as it is pressed, and the contacts return to their original position when the hand is released. For example, the button that turns on the hot water in a kettle is a momentary type.

Momentary rocker switches function only while the button is depressed, and return to their original function when the button is removed from the hand.

2. Alternate Type Rocker Switch

Alternate Rocker Switches switch the electrical circuit when the switch is pressed, and the contacts are held until the switch is pressed again. For example, a switch that turns on the lights in a room is an alternate type.

An alternate rocker switch switches between ON and OFF each time the button is pressed.

Other Information on Rocker Switches

Number of Rocker Switch Terminals and Connection Methods

Rocker switches are simple in construction, but care must be taken in their selection. When selecting a rocker switch, it is necessary to consider the current and voltage supported, the resistance of the switch itself, its size, and its durability in relation to temperature and operating environment. Especially important to know is the number of rocker switch terminals and the method of connection.

Connecting rocker switches is easy if you simply turn them on and off. If it has two terminals, connect one to the power supply and the other to the device. If the rocker switch has three terminals, connect one to the power supply and one of the remaining two to the device. It is common practice to check the continuity of the circuit with a tester before connecting the terminals to distinguish between the terminals for the power supply and the terminals on the contact side.

Some rocker switches have four or more terminals. This is the case when a light bulb for lighting is built inside the rocker switch. The breakdown of the terminals is a circuit that feeds power to the device and a power ground for the bulb.

To connect a rocker switch with four terminals, connect the power supply to two terminals for a rocker switch with built-in lighting, connect one to the device, and then connect the ground wire for the lighting inside the rocker switch. Of course, note that the internal circuitry varies depending on the rocker switch used.

Check the electrical circuit in the instruction manual that comes with the rocker switch or use a circuit tester to check the continuity of the internal circuit before making wiring connections. If wiring connections are made blindly, the switch may not operate as expected, and in the worst case, the rocker switch or equipment may be damaged.