What Is an Emergency Stop Switch?

An emergency stop switch is a critical safety device designed to halt equipment operations in emergencies, protecting against serious accidents and injuries. These switches are essential in environments where industrial machinery operates under high torque or pressure, posing risks to human safety.

Uses of Emergency Stop Switches

These switches are commonly found in machinery such as conveyors, presses, and welding robots, where there’s a risk of entrapment or pinching. Regulations often mandate their installation on equipment like conveyor belts to prevent entrapment accidents. Pull-rope switches are preferred in some cases for their accessibility along the length of a conveyor.

Principle of Emergency Stop Switches

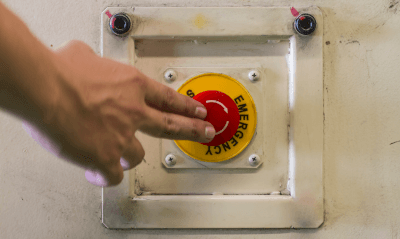

- Push-Button Type: Typically red for visibility, these switches lock when pressed to ensure machinery remains halted until manually reset. They’re designed to interrupt electrical circuits to stop equipment immediately.

- Pull-Rope Type: Used around conveyors, pulling a wire attached to the switch stops the machine. Like push-button types, these switches lock upon activation and require manual resetting.

Other Information on Emergency Stop Switches

- Installation Considerations: The placement of emergency stop switches is crucial for easy access by workers. In large facilities, multiple switches are installed to ensure availability in any emergency.

- Lockout Mechanism: To prevent accidental restarts that could lead to injury or death, some emergency stop switches feature a lockout mechanism. This allows the switch to be padlocked, ensuring that equipment cannot be restarted until it’s safe to do so.