What Is a Terminal Block?

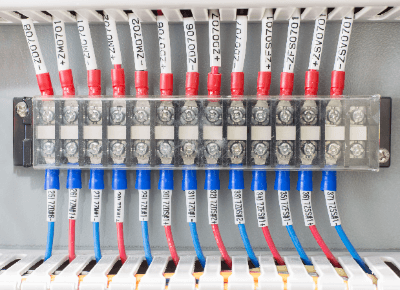

A terminal block is a row of terminals that connect external wiring to internal circuits. They are used in distribution boards and power distribution boards.

Electric wires are treated with crimp terminals and fixed to the terminal block. Screw-fastening and screwless types are available for terminal blocks.

Two-stage types and oil-and chemical-resistant types are also available. Voltage and continuity can be measured on the terminal block using a tester.

Uses of Terminal Blocks

Terminal blocks are used to connect circuits inside the panel to external wiring. Terminal blocks are used in distribution boards, switchboards, breakers, noise filters, aerospace, relays, air conditioning controls, and more.

Depending on the application, there are many types of terminal blocks to choose from. For example, for interface use, there are dedicated interface terminal blocks that are compact and convenient with many terminals. In addition, terminal blocks for grounding, fuses, and other applications are available.

Principle of Terminal Blocks

Terminal blocks are divided into conductive boards and components such as plastic girders.

Conductive boards are made of conductive materials and are used to conduct electric current between wires. The plastic frame is the part that insulates the electric circuit to prevent ground faults.

Crimp terminals are used to connect the conductive plate to the wires. Although crimp terminals alone may be used, it is safer to protect them from electric shock with marked tubes or insulating caps.

The crimp terminal is clamped under the screw attached to the conductive plate. The current can flow through the conductive plate. Generally, do not fasten more than three wires to a single screw. The purpose is to prevent increased contact resistance.

Do not allow wires to ride on top of equipment or fixtures to avoid electric shock or ground fault. Before use, check the specifications of the terminal blocks to ensure that the current and voltage are within the allowed range.

Screwless types are convenient because they do not require terminals and can be used by stripping the wires and inserting them directly into the terminal blocks.

Resin mounts are available in thermoplastic and thermosetting resins, which differ in heat and chemical resistance. Screws and conductive plates are made of copper, stainless steel, chrome plating, or other conductive metals, and many products are RoHS compliant.

Types of Terminal Blocks

Apart from the classification of connection methods, there are convenient terminal blocks with various functions.

1. Common Terminal Blocks

Standard terminal blocks, in which each terminal connection is connected internally, are mainly used for power distribution. 10-circuit, 20-circuit, plug-in type, screw connection, and other types are available and are selected according to the specifications of the equipment.

2. Connector Terminal Blocks

Connector terminal blocks are used to convert connectors of various standards into terminals. Connectors are connected to terminal blocks, and wires are connected to the terminals corresponding to the connector pins without soldering.

Many connectors can be used, and products compatible with various connectors such as D-Sub, MIL, and FCN are available. Terminal connections are also available with screw connections, plug-in types, etc.

Connector terminal blocks are often used for IO connections to PLCs; I/O can be input/output to PLCs by connecting the IO connector of the PLC to the connector terminal blocks with a cable and wiring I/O to the terminal blocks, thereby reducing wiring person-hours.