What Is a Fiber Optic Sensor?

A fiber optic sensor is an optical waveguide inside a thin fiber-like optical fiber made of resin or quartz glass, which is used for various sensing applications in manufacturing sites.

A fiber optic sensor is an optical waveguide inside a thin fiber-like optical fiber made of resin or quartz glass, which is used for various sensing applications in manufacturing sites.

Fiber optic sensors have a flexible, thin cable and a small sensor head that enables detection in confined spaces and detection of small objects, and are suitable for detection in a wide range of environments because they are not affected by electromagnetic influences. Depending on the material of the optical fiber coating, fiber sensors can also be used in high-temperature environments or in the presence of oil or chemicals.

Uses of Fiber Optic Sensors

The main application of fiber optic sensors is object detection. They can detect the presence or absence, passage, or moving speed of an object in the detection area where light is irradiated.

Since fiber sensors detect by shading or reflecting light, they can detect the presence or absence and color of general solids such as wood and resin as well as metals, and can also detect transparent glass, etc. They are widely used in various manufacturing sites, from non-contact general product detection to detection and the positioning of extremely small products in narrow spaces.

In addition, fiber optic sensors can detect not only solids but also liquids, strain, and temperature, and current sensors that measure the current value flowing through conductors without contact are also in practical use.

Structure of Fiber Optic Sensors

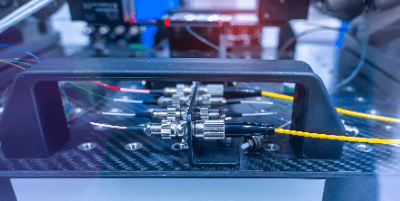

Fiber optic sensors are composed of a light emitting part, which consists of a cable-like fiber unit that emits light while passing it through and a fiber amplifier that has a light source and optical amplification functions, and a light receiving part that receives the light.

The optical fiber, which is the core of the fiber unit, consists of a core with a high refractive index and a cladding with a low refractive index.

Fiber amplifiers are mainly structured with optical amplifiers and detection circuits between the light emitter and receiver. Rare earth doped fiber is used as the most important optical amplifying medium, and detection is performed by amplifying the incident light through the induced emission of excitation light. Depending on these features, some products are equipped with sensitivity adjustment and the ability to set or change threshold values.

Fiber optic sensors can be broadly classified into two types: those with separate fiber units and fiber amplifiers and those with built-in fiber amplifiers, and their detection methods include transmission, reflection, retro-reflection, and limited reflection types.

Principle of Fiber Optic Sensors

Fiber optic sensors perform various types of detection based on the information (wavelength and light intensity) of light emitted from the light-emitting part and received by the light-receiving part.

1. General Object Detection

The most basic detection principle is to detect the presence or absence of an object when the light from the light-emitter to the light-receiver is interrupted. It is possible to detect the passage of an object by blocking the light for a short period, or to measure the speed of movement of an object by measuring the reflection time if a light-receiving means is also provided on the light-emitting side.

Although transparent objects such as glass are difficult to detect because light passes through them, detection is possible by precisely measuring the change in light intensity due to the change in refractive index on the surface (air ⇔ glass).

2. Detection of Liquids

Fiber Optic Sensors are used to detect not only solids but also liquids by utilizing the light refracting property of liquids.

The tube-mounted type projects light from the wall of the tube. If there is no liquid in the tube, the light travels straight ahead, and if there is liquid, the light is refracted and enters the light-receiving side. This allows detection of the presence or absence of liquid. This type can detect transparent liquids, but not opaque liquids that do not allow light to pass through.

In the wet type, the light emitter and receiver are placed parallel to each other inside a conical resin tube, and when not in contact with liquid, the light is refracted by the cone and returns to the light-receiving side. When wet, the refractive index changes and light does not return. This is how wetted liquid is detected.

In this way, fiber sensors are used to detect the presence of liquid, liquid level, and water leakage. In the detection of liquids, the resin tubes are often made of Teflon, which can be used for chemicals and high-temperature water, and are applicable to a wide range of applications.

3. Color Detection

The color of an object is determined by the wavelength distribution of the reflected light according to the reflectance or refractive index relative to the wavelength (color) of the irradiated light. This can be used to detect color with a fiber sensor.

4. Detection of Temperature and Strain

Optical fiber has a dual structure of core and cladding in the radial direction, but by irradiating special ultraviolet light in the manufacturing process, regions with partially different refractive indices can be generated at regular intervals in the axial direction. The image of an optical fiber in this case is a series of cylinders with FBGs at both ends.

Since FBGs reflect only specific wavelengths depending on the spacing and refractive index generated, when the optical fiber expands or contracts due to temperature changes, the wavelength of the reflected light and the time it takes for the reflected light to return will change. This allows the fiber to be used as a temperature sensor.

Also, when installed in a structure, the fiber length changes with the distortion of the structure, making it possible to use it as a strain sensor. In addition to large buildings, tunnels, pipelines, etc., the sensor can be applied to structures that are constantly subjected to external forces, such as offshore wind power generation, which is a form of renewable energy. When a weight is connected, the length of the optical fiber changes according to the acceleration force applied when the weight moves, so it can also be used as an acceleration sensor.

5. Detection of Current Value

The Faraday effect is used to detect the current value using a fiber sensor. When an electric current flows through a conductor, a concentric magnetic field is generated according to the right-hand thread law. The Faraday effect is a phenomenon in which the polarization plane of light passing through an optical fiber along this magnetic field rotates according to the intensity of the magnetic field. The current value is detected by measuring the angle of rotation of the polarization plane.

Other Information on Fiber Sensors

About Fiber Amplifiers

Fiber optic sensors generally use LED light, which is carried by an optical fiber to the detection area and illuminated by a lens. The most common problems with fiber sensors is the deterioration of the LED light over time and adhesion of dirt on the lens. When these conditions occur, the light intensity of the irradiated light decreases, causing false detection and leading to equipment trouble, so fiber amplifiers are used.

The function of the fiber amplifier is to detect and compensate automatically for the decrease in light intensity. It detects changes in LED light over time and raises the output accordingly to maintain the light intensity at a constant level. It also sets object detection by the rate of decrease rather than the amount of decrease in light intensity and automatically compensates by judging the relative light intensity ratio between the emitting and receiving light.

In this way, products and functions that compensate for the shortcomings of fiber optic sensors are being developed one after another, and their good use will prevent problems.