What Is a Precision Stage?

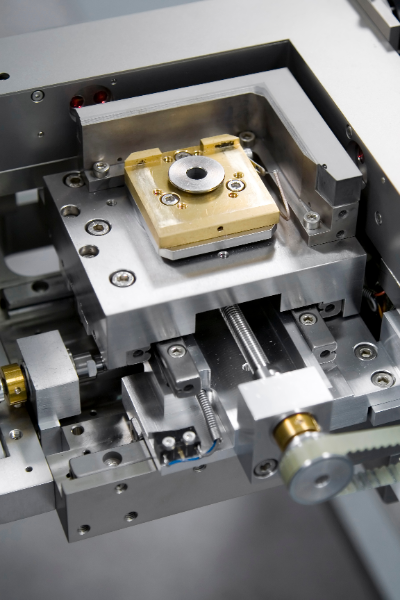

Precision stages are stages that can be moved precisely in the X-axis, Y-axis, and rotation directions. The number of axes that can be moved varies depending on the model, and there are various types of precision stages ranging from 1 to 4 or more axes.

Precision stages are stages that can be moved precisely in the X-axis, Y-axis, and rotation directions. The number of axes that can be moved varies depending on the model, and there are various types of precision stages ranging from 1 to 4 or more axes.

The stage is moved by a feed screw with a small pitch, and a micrometer or motor with a reduction gear is used to move the table on the order of micrometers, which is used for observation of extremely small samples.

While the stage can be moved precisely, the range of motion is only a few centimeters, making it unsuitable for applications that require the stage to be moved significantly.

Applications of Precision Stages

Precision stages can be moved independently and precisely in each axis direction, such as X-axis, Y-axis, Z-axis, and the three rotational axes, and are used for applications that require precise control of sample positioning.

They can be used as stages for microscopes to observe micro objects such as semiconductor devices, stages to fix workpieces for precision machining, stages for optical lens inspection such as optical axis alignment, and stages for joining parts with high-precision positioning. Precision stages are used for high-precision positioning and joining of parts.

Principle of Precision Stages

Precision stages consist of a high-precision linear guide, a feed screw, and a micrometer or motor with a reduction gear to rotate the feed screw, and as many of these mechanisms as there are moving axes. When the feed screw is extended one time, the stage moves by the pitch of the screw (a few tenths of a millimeter).

When a micrometer is used, the amount of movement can be determined by reading a special scale engraved on the micrometer.

When a motor is used, a rotary encoder is built into the motor to detect the number of rotations, thereby controlling the stage travel.

Precision stages are available in a wide range of configurations, from 1-axis X-axis stages to 2-axis X- and Y-axis stages, and from 3-axis to 6-axis stages including Z-axis and rotation, depending on the application. However, the more axes a precision stage has, the more expensive it is, so it is recommended to select a stage with the minimum necessary specifications.