What Is a Simple Filtration Device?

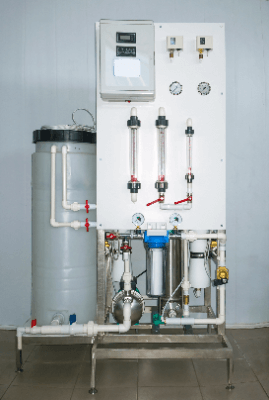

Simple filtration devices pass liquids containing pollutants through perforated filtration materials such as paper, cloth, wire mesh, glass cotton, sand, and synthetic fibers.

Simple filtration devices pass liquids containing pollutants through perforated filtration materials such as paper, cloth, wire mesh, glass cotton, sand, and synthetic fibers.

Filtration devices clean liquids by passing them through perforated filter media such as paper, cloth, wire mesh, glass cotton, sand, and synthetic fibers, separating out individual particles that are larger than the pores.

Physical forces such as gravity, pressure, vacuum, and centrifugal force are sometimes used to facilitate filtration, but the most economical and convenient method is to use a coagulation

The most economical and convenient method is to simply flow the wastewater through a filter and separate it into solids and liquids.

Applications of Simple Filtration Devices

Simple filtration devices are used in the following fields: brittle materials processing, mold making, wastewater, tap water, food waste, pool and bath water, tool making, metals, machinery, minerals, etc.

metal, machinery, minerals, and other fields.

Examples of applications include:

- Rill and end mill chip production

- Filtration of brittle materials, such as ceramic, glass, and quartz

- Filtration of concentrated sludge

- Filtration of wastewater

- Filtration of chemical coagulation sludge

- Food waste treatment

- Filtration of coolant liquid for polishing machines, electric discharge machines, wire-cut electric discharge machines

- Filtration of sludge in coolant tanks

- Filtration of swarf from machine tools

- Filtration of sludge in a sewage system

- Removal of hair, grime, and other debris with sand and the cartridges in filtration equipment

- Removal of rust with filters of water purifiers

Principle of Simple Filtration Devices

Simple filtration devices are constructed so that the filtration material with the largest pores is the first to be filtered, and as filtration progresses, the pores become smaller and finer

As filtration progresses, the smaller pores and finer filtration materials are passed through.

To increase the effectiveness of filtration of pollutants, wastewater containing organic solvents such as paint may require the addition of a coagulant or cation adsorbent for solidification treatment in specified quantities.

A specified amount of coagulant or cation adsorbent may be added.

When a flocculant is added and stirred for a certain period, the liquid undergoes a flocculation reaction, creating wastewater that is a mixture of solid and liquid containing contaminants.

When wastewater containing a mixture of solids and liquid is poured into a filter material with a large mesh, large sediments can be roughly removed. Next, the wastewater is poured through filter media with smaller meshes.

The more it passes through sequentially smaller pore size filtration media, the more only the cleanly purified liquid remains.

The final filtration material used in the simple filtration device varies in pore size, but is made of synthetic fibers, rayon, or polyester with an accuracy of 1.0 to 100 microns.

Polyester is used for the final filtration material, which has a pore size range of 1.0 to 100 microns. Polyester materials have excellent oil adsorption properties. Other special filters can be used for filtration of glass and ceramics.

Other filtration materials include special filters that can also be used for filtration of glass and ceramics.