What Is a Board-To-Board Connector?

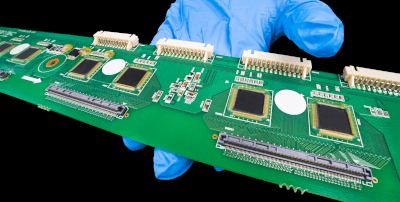

A board-to-board connector is a component used to electrically couple circuits on two printed circuit boards.

They are mounted directly on both boards to be connected, and are bridged by a cable with connectors attached to both ends of the cable.

A male connector on the printed circuit board and a female connector on both ends of the cable are used to connect the two boards together, thereby directly connecting the boards electrically.

Furthermore, some board-to-board connectors do not use cables with connectors for bridging, but directly connect the board-to-board connectors on both printed circuit boards to directly connect the two boards electrically.

Uses of Board-To-Board Connectors

Board-to-board connectors are available in various sizes of signal cables and pins in the connectors, depending on the location of use and the required current capacity.

What is required of board-to-board connectors is how many signal cables can be accommodated in the connector and how well they can be maintained in a stable electrical and physical connection.

Board-to-board connectors are almost certainly used in all types of equipment that use printed circuit boards, including most consumer and commercial equipment.

Without exception, these devices are becoming increasingly sophisticated and high-performance, and with this trend comes the need to reduce board space, resulting in the need for all electrical components, including board-to-board connectors, to be smaller, thinner, and lighter.

Principle of Board-To-Board Connectors

As mentioned above, the purpose of a board-to-board connector is to electrically and directly connect two printed circuit boards.

Originally, if all functions could be realized on a single board, there would be no need for a board-to-board connector, and this method is considered to be the most cost-effective and inexpensive.

However, in order to implement all required functions within the limited physical space of a device, it is practical to divide the board into multiple boards of appropriate sizes and insert them into the device to secure space inside the device.

In addition, there are significant advantages to be gained by dividing PCBs by function, which ultimately leads to cost reductions in the equipment.

By dividing the printed circuit board into multiple boards for each functional unit and combining these multiple boards, it is possible to realize multiple products with various functions at the same time. In this case, board-to-board connectors that combine multiple boards are effective.

For example, suppose that there are three boards to realize the necessary functions in designing a certain product: board A for basic functions, board B for additional functions, and board C for additional functions.

By using only board A, a product with the most basic functions can be realized, and by using boards A+B, a product with added function B, A+C, and A+B+C, a product with added function B, and a product with added function B+C, respectively, can be realized.

In other words, four types of products can be realized by preparing boards with three functional units and combining them.