What Is a Stainless Steel Grating?

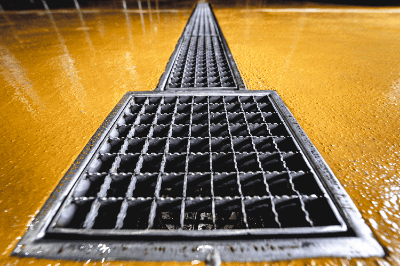

Stainless Steel Grating is a steel grating product used for floor surfaces.

It is made of stainless steel, and is generally used for floor ventilation, water drainage, and slip prevention, for example, in factories and public places.

Uses of Stainless Steel Grating

Common uses of grating are as follows:

1. Drainage

Gratings are used for efficient drainage of water. For example, they are found in bathhouses, around swimming pools, in stormwater runoff areas, and in drainage channels. The grating structure allows water to pass through, preventing puddling and helping to reduce flood damage.

2. Ventilation

Used for floors in industrial facilities, machine rooms, subway stations, etc. Where ventilation is required, grating ensures air flow and supports ventilation.

3. Anti-slip

Gratings are used to improve safety when walking or moving vehicles in slippery areas. They are especially common in wet environments or where liquids may spill onto the floor. They are commonly found in factories, warehouses, ship decks, pedestrian bridges, etc.

4. Visual Effects

Gratings are sometimes used in locations with visual effects. Gratings made of transparent materials are sometimes used in underground station platforms and elevated walkways to visually connect the visible space below. This ensures brightness and reduces a sense of claustrophobia.

5. Design Elements

Gratings are also used as design elements in buildings and public areas. They serve as a beautiful design or decorative element in flooring materials. They may be employed as part of landscape design or building exteriors.

Principle of Stainless Steel Grating

The principles of grating are based on the principles of drainage and ventilation. Gratings are structures that help water and other liquids pass through the floor surface and drain downward. To accomplish this, grating has grooves or holes.

This keeps water from pooling on the floor surface. Additionally, some grates may be sloped to allow water to flow more easily downward. Gratings are also products used in areas where ventilation is needed; they have an open structure that allows ambient air to pass under the floor.

Features of Stainless Steel Grating

1. Corrosion Resistance

Stainless steel is a corrosion-resistant material. It has better corrosion resistance than steel grating floors in grating floors used in water, humid environments, chemicals, and salty environments. This property provides long-lasting durability and low maintenance.

2. Load-Bearing Capacity

Stainless steel is a tough material and may have higher load-bearing capacity than non-stainless steel grating. It performs well on platforms subjected to heavy machinery and loads, and in areas subject to frequent pedestrian and vehicular traffic.

3. Hygienic

Stainless steel is a hygienic material because it has a smooth surface and is resistant to dirt and bacteria. It is suitable for grating used in food processing facilities, medical institutions, and other locations where environmental cleanliness is required.

4. Appearance and Design

Stainless steel has a beautiful appearance and is suitable for modern design. It can provide functionality while maintaining a beautiful appearance, especially in buildings and public places.

Types of Stainless Steel Grating

The main types of grating are as follows:

1. Steel Grating

Welded steel grating, durable and load-bearing. Used in factories, warehouses, platforms, etc. Stainless Steel Grating is also included here.

2. Aluminum Grating

This grating is lightweight, corrosion-resistant, and has excellent ventilation properties. It is sometimes used in outdoor facilities and places where light loads are applied.

3. FRP Grating

FRP grating is a plastic grating reinforced with glass fiber. Lightweight, corrosion-resistant, and electrically insulating, it is sometimes used in chemical plants and electronic facilities.

4. Wood Grating

This grating is made of wood. They have a beautiful appearance and are found in some parks, gardens, and promenades.

5. Plastic Grating

Lightweight, chemical-resistant, and electrically insulating, it is often used around chemical facilities and electronic equipment. It is also sometimes used around swimming pools.

How to Select Stainless Steel Grating

Stainless steel grating is selected when it is necessary to withstand corrosion, such as in coastal areas, or when it is necessary to maintain the beauty and appearance of the landscape by gloss. In addition, stainless steel grating should be selected in terms of load capacity, grating width, and anti-slip properties.

The appropriate load should be selected according to the location and purpose of use. It is important to select an appropriate load, because the grating may be deformed or damaged if the load is exceeded.

In addition, the width of the grating can be varied to change the size of the passing object. Fine grating widths are used in places where there is a risk of wheels falling off, such as carts, etc. The size and roughness of the grating are specified according to the groove width used in JIS standards, etc., so it can be used in accordance with the groove regardless of the manufacturer.

It is important to select a grating with high anti-slip properties for outdoor and humid places. Slip-proof grating can be prevented by changing the shape of the surface.