What Is a Sludge Dehydrator?

A sludge dehydrator is a device used to remove water from sludge. They are used in facilities that treat sewage using the activated sludge method to draw out excess sludge and maintain the proper amount of microorganisms.

A sludge dehydrator is a device used to remove water from sludge. They are used in facilities that treat sewage using the activated sludge method to draw out excess sludge and maintain the proper amount of microorganisms.

There are various types and names for sludge dehydrators, including vacuum dehydrators, pressure dehydrators, screw press dehydrators, belt press dehydrators, centrifugal dehydrators, and multiple disk dehydrators.

Uses of Sludge Dehydrators

Sludge dehydrators are mainly used for sludge treatment in wastewater facilities. In facilities that use the activated sludge method to treat sewage, excess activated sludge is called excess sludge, and if the excess sludge is not periodically removed from the facility, the number of microorganisms in the sludge will increase, creating an environment that makes it difficult for young microorganisms to be born in the tank, thereby reducing sewage treatment capacity.

The sludge dehydrator is a device used to remove the excess sludge from the facility. The excess sludge can be treated by using a pump to draw the sludge out from under the settling tank, which is called a sedimentation tank, and feed it to the sludge dehydrator.

Principle of Sludge Dehydrators

Slaked lime and flocculants are used to alter the fine particles in the sludge and change their properties to make them easier to separate.

The following is a description of each type of dehydrator.

1. Vacuum Dehydrator

In the case of vacuum sludge dehydrators, the sludge is first mixed with a flocculant to make sludge filtrate. A rotating drum covered with filter cloth is dipped into the sludge filtrate and rotated at low speed by a motor.

Since the inside of the drum is under negative pressure by a vacuum pump, a suction force is generated to draw air from the outside of the drum. This suction force draws the sludge filtrate into the drum, but because the drum is covered with a filter cloth, only the water penetrates the filter cloth, and only the dewatered sludge sticks to the filter cloth. The water that penetrates the filter cloth is drained by the filtration pump, and the sludge stuck to the filter cloth is discharged as dehydrated cake.

2. Belt Press Dehydrator

The belt press dehydrator has a number of built-in rolls, between which two pieces of filter cloth are passed. Sludge filtrate mixed with a coagulant is placed in the filter cloth and pressed between the two filter cloths to squeeze out only the water from the filtrate, and only the dewatered sludge is discharged.

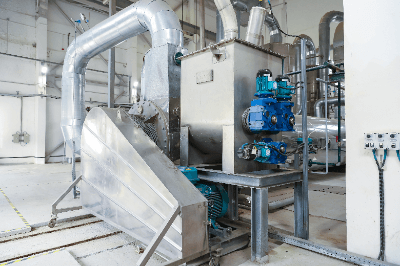

3. Screw Press Dehydrator

A screw press dehydrator consists of a cylindrical screw inside a tank called a screen, which is rotated at low speed by a motor. The closer the screen is to the discharge section, the narrower the screen becomes, and the pressure between the rotating screw and the screen gradually increases. The sludge filtrate is fed into the screen, and is then wound up by the screw, moving forward. The closer to the discharge section, the stronger the pressure becomes and the more water is dewatered.

4. Centrifugal Dehydrator

Centrifugal dehydrators de-water sludge filtrate by centrifugal force. After the sludge filtrate is fed into the rotating cylinder, the cylinder is rotated at high speed, causing the sludge to accumulate on the inner wall of the cylinder. The sludge is then drained and discharged by the screw inside the rotating cylinder, which rotates at a slightly slower speed than the rotating cylinder.

5. Multiple Disk Dehydrator

The multiple disk dehydrator consists of many stainless steel or plastic disks, which are placed on top and bottom, and rotated to convey the sludge while dehydrating it. By rotating the filter, only the water is filtered through the gaps in the filter. Compared to other dewatering machines, it is less prone to clogging, are easier to clean, and do not require vacuum or pressurization equipment.