What Is an HL Finish?

An HL finish is a surface treatment in which fine scratches are applied to the surface of stainless steel products in a certain direction using a belt grinder coated with an abrasive.

An HL finish is a surface treatment in which fine scratches are applied to the surface of stainless steel products in a certain direction using a belt grinder coated with an abrasive.

It is called HL (hairline) finish because the fine scratches applied to the surface are as fine as a hair. Although HL finish is part of the surface treatment design, the abrasive scratches have a matte effect and the metallic luster is subdued, giving the product a refined, high-quality finish.

In addition to the visual splendor of the HL finish treatment, the surface irregularities created by the polishing process also provide an excellent anti-slip function. Because it combines design and functionality, it is often used in places where people can see or touch it.

HL finish is one of the most common surface treatments for stainless steel products.

Uses of HL Finishes

HL finish is used in a wide range of applications, from everyday objects to public places.

- Public Facilities or Public Institutions Such as Schools, Hospitals, and Train Stations

Handrails, gates, anti-collision fences, ramps, etc. - Restaurants

Kitchens, counters, etc. - Commercial Facilities, Supermarkets, Convenience Stores

Handrails, cart guards, fall prevention fences, etc. - Residences, Personal Effects, Etc.

Kitchens, sinks, watches and accessories

Mirror finish is classified in the same finish treatment design. As the name suggests, this is a process in which the surface is polished so shiny that one’s own reflection can be seen, just like a mirror. Mirror finish has a beautiful appearance, but it is not suitable for practical use because it easily shows dirt.

In contrast to the mirror finish, the HL finish uses polishing to reduce the luster. Therefore, it is widely used as a surface finish that is easily accustomed to everyday use, as it is less likely to show scratches, fingerprints, and other stains that are created during use and is more practical.

Principle of HL Finishes

HL finish is mainly applied using a belt grinder. The abrasive belt attached to the belt grinder rotates at high speed while coming into contact with the object, polishing the surface and creating countless scratches. This process is carried out in a fixed direction to apply the HL finish to the surface.

There are many types of abrasive belts used in the HL finish. By using different abrasive belts, the width and shape of the line can be freely selected to achieve the desired hairline pattern and texture. In addition, HL finish is applied along the longitudinal direction (longer dimension) of the object.

The longitudinal direction increases uniformity and improves the appearance of the product. Depending on the product, HL finish is often applied only to the visible side (one side), rather than to the entire surface, as it is a type of design. The single-sided finish can reduce the cost of production and create a great advantage for the client.

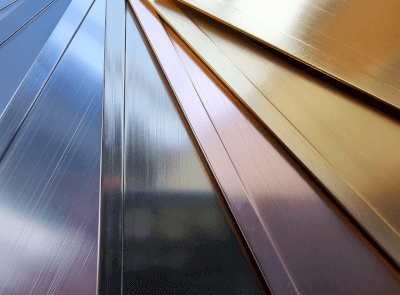

Types of HL Finish

HL finish is classified into different types according to the width of the line to be processed and the method of applying the pattern. Typical types of HL finishes are as follows:

1. Hairline

Although there are some differences among manufacturers, this specification is presented as a general hairline.

2. Scratch Hairline

A shorter line pattern is applied compared to the general hairline. It is characterized by a slightly coarser finish.

3. Hairline Cross

This is a processing treatment in which the hairline pattern is applied in a cross pattern, whereas the general hairline is a vertical line in a fixed direction. The finish is reminiscent of Japanese paper.

4. Design Hairline

This is a polishing process in which the hairline pattern is applied in a woven pattern. The woven knit-like finish gives a soft impression. Some manufacturers can also provide HL finish with a design of their own choosing, in which case it is classified as a design hairline.