What Is a Hot Knife Cutter?

A hot knife cutter is a cutter that uses the force of heat to cut molten material.

They are also called “hot cutters” or “hot knives.” A hot knife cutter for styrene foam is called a “styrene cutter.”

Uses of Hot Knife Cutters

Figure 1. Nylon rope and cell tray

Heat knife cutters are used for cutting heat-soluble materials such as plastic, acrylic, nylon, polyester, styrofoam, and polyvinyl chloride, etc. They are often used in DIY, handicrafts, and gardening situations.

It can be used to cut plastic and plastic bottles for crafts, and to cut acrylic and styrofoam into desired shapes. It is also easy to cut nylon and polyester fabrics, ropes, and nets, as well as cell trays and plug trays used in gardening.

It is also used for weathering plastic models. Hot knife cutters can be used to create scars caused by bullets or beam weapons. They are also useful for disposing of large plastic products and Styrofoam, as they can be easily disassembled.

Principle of Hot Knife Cutters

A hot knife cutter cuts heat-soluble materials by heating the blade with the power of electricity. Although heat-soluble materials can be cut with ordinary scissors or cutters, hot knife cutters use the power of heat to speed up the cutting process and produce a smooth, clean cut.

Nylon and polyester materials are welded to the cut surface, so there is no risk of fraying after cutting. Another feature of this type of heat cutter is that it does not easily produce shavings or other debris.

How to Choose a Hot Knife Cutter

The following three points should be considered when selecting a hot knife cutter.

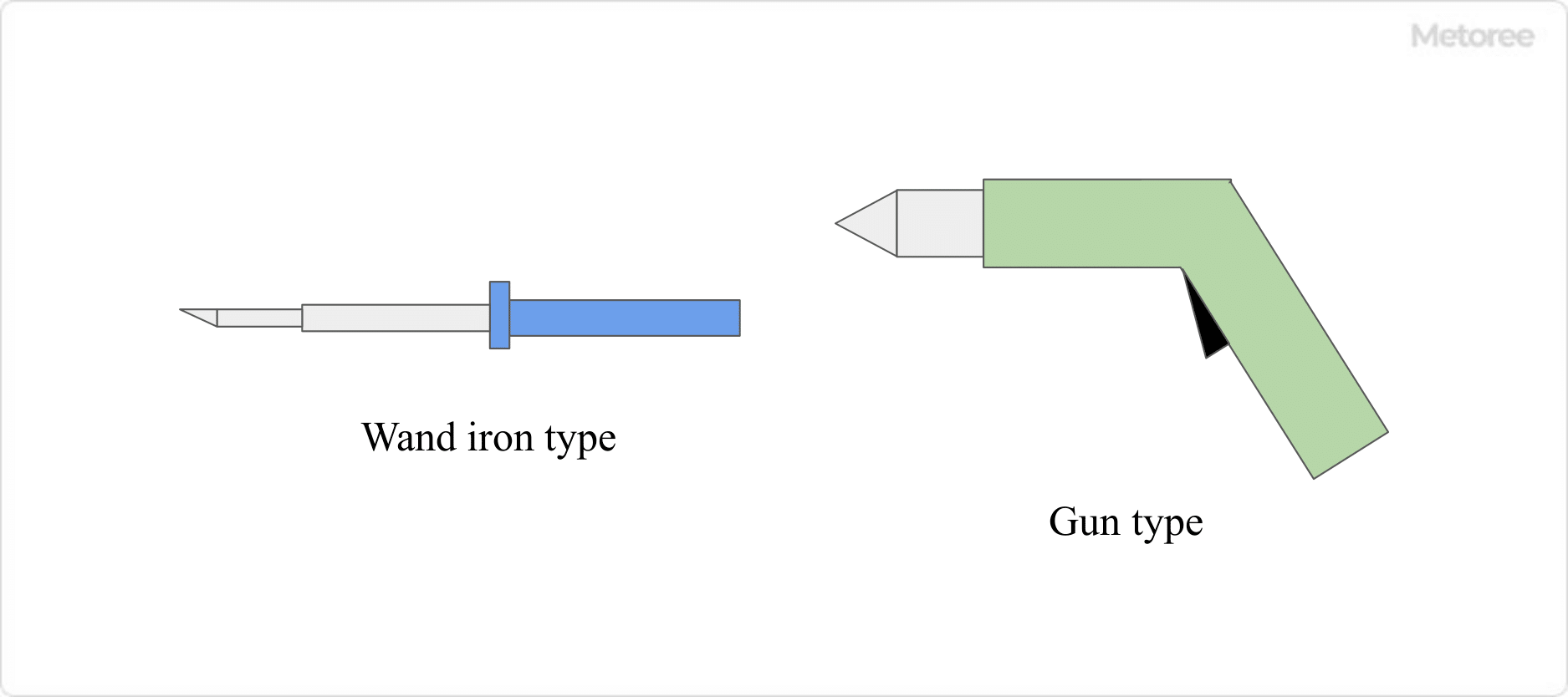

1. Soldering Iron Type and Gun Type

Figure 2. Wand soldering iron and gun type

There are two types of hot knife cutters: soldering iron type and gun type. The small soldering iron type is recommended for cutting thin and small objects. It is also suitable for fine cutting work.

For cutting thick and large objects, the large gun type is better. It has more power, but it is also heavier, so it should be handled with care.

2. Attachment Type Blade

Some products have attachable blades that can be changed according to the material to be cut. This is useful for cutting a variety of materials.

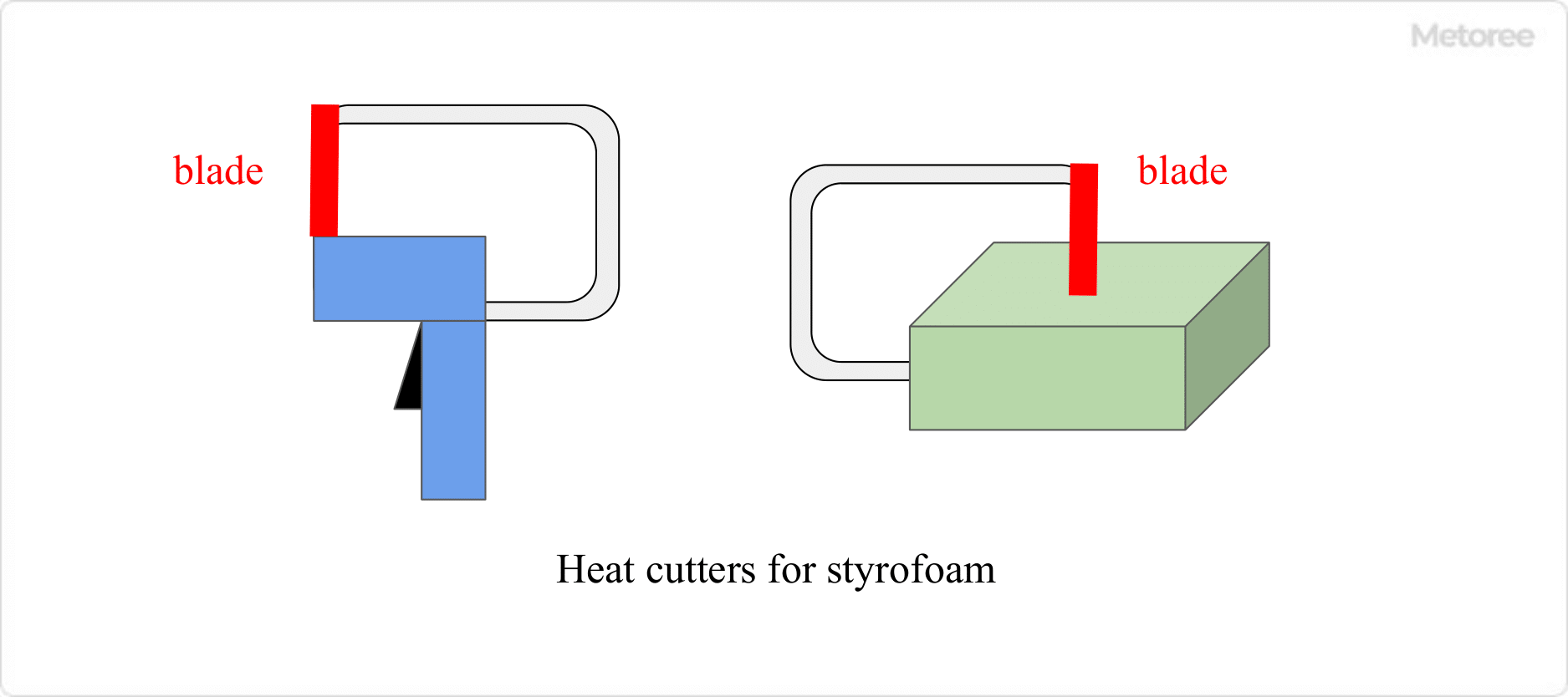

3. Hot Knife Cutter for Styrene Foam

Figure 3. Heat cutters for styrofoam

When cutting Styrofoam, a bow-shaped hot knife cutter is easy to use. If you want to work in a stable manner, tabletop hot knife cutters are also available. The tabletop has guides drawn on it for accurate cutting.

Other Information on Hot Knife Cutters

How to Use a Hot Knife Cutter

To use a hot knife cutter, turn it on and wait a certain amount of time for the blade to heat up. The fastest ones can be used in about 10 seconds, depending on the product. For slower ones, you need to wait a few minutes. When the heated blade is applied, the material melts and is cut, just like cutting butter.

You need to be careful not to let the blade touch anything other than the area you want to cut. It is also helpful to have a stand on which to place the hot knife cutter and a heat-resistant cutter mat so that the desk or floor on which you are working will not be burned. The temperature of the blade can rise from 100°C to 500°C. A type of hot knife cutter that does not have a hand-held switch will stay heated as long as it is plugged in.

It is safer to unplug the outlet each time when not working continuously. Failure to do so may cause a fire. Also, it is important to work in a well-ventilated area, as the melting of the material tends to produce a small amount of smoke and an unpleasant odor.

As the hot knife cutter is used, melted debris from the material may stick to the blade. In such cases, the blade can be easily cleaned by keeping it in a heated state and scrubbing it with a brass brush. Chrome-plated blades are also resistant to melting debris.