What Is a Cutting Service?

Cutting service is a general term for a process used to cut an object into two pieces.

It is used to combine materials for machine parts, such as round bars or plates. Common cutting services include using sword blades, scissors, and saw blades as tools, melting the material to be cut with a flame, and cutting by spraying fine powder.

When cutting out materials, machine tools that match the shape of the material are used. Pipe, angle, and channel materials are easy to machine.

Uses of Cutting Services

There are a wide variety of processing methods depending on the target material. By using the appropriate cutting service, the best procedure can be used.

For example, laser cutting services can be used for a wide range of applications, such as sheet metal, accessories, and signboards, because the material can be cut according to the created data. The thickness that can be cut varies depending on the material.

Wire-cut EDM can be used for cutting services for hard materials such as ceramic and tungsten. Waterjet machining is suitable for machining rubber and reinforced plastics that are easily deformed by heat. Milling is used for spacers for machine parts, while turning is used for shafts and bearings.

Types of Cutting Services

1. Cutting Service by Lathe Turning

The lathe is capable of various cutting processes. A butt cutting tool or other tool is attached to the lathe to cut bars and other workpieces. This cutting service is used at the end of the process when the bar or other workpiece is longer than the desired length.

2. Cutting Service by Milling

A lathe is used for a wide variety of cutting services, and tools such as metal saws can be attached to the lathe for cutting services.

3. Cutting Service by Press Working

Two blades are prepared at the top and bottom of the workpiece and pressed to cut the workpiece to the desired size and shape. In this case, it is often called shearing, a type of cutting service.

4. Cutting by Laser Cutting

Cutting is performed by laser. Complex shapes can be cut.

5. Cutting Service by Water Jet

Cutting is performed by jetting water under ultra-high pressure through a nozzle with an extremely small diameter.

6. Cutting by Wire Cutting

Cutting is performed by electrical discharge using electrode wires. Complex shapes can be cut.

How to Choose a Cutting Service

A wide variety of machine tools are used for cutting services.

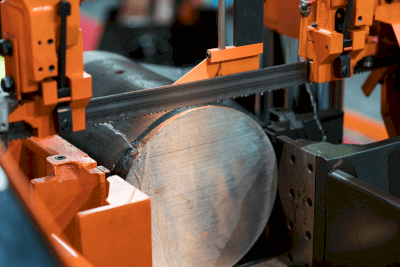

1. Bandsaw Machine

A bandsaw is used to cut plates. The band aw has a blade of about 8 mm in width that rotates from top to bottom to cut the material. When cutting boards with the band saw, a shaving margin (3 to 5 mm) should be taken into account. If you use military gloves, you may get caught in the blade, so do not use them and hold the material firmly with both hands. However, do not place your fingers in the direction of the blade.

2. Bow Sawing Machine

A hacksaw is used to cut round bars. The hacksaw automatically moves the blade back and forth. By placing the blade on a fixed material, a round bar can be easily cut. Fix the material at an appropriate length and move the bow saw blade. Slowly place the blade over the material and the cutting will be completed automatically.

3. Handsaw

When cutting round bars with a diameter of 10 mm or less, use a handsaw instead of a hacksaw. The reason is that the blade of the hacksaw will be damaged. When cutting materials with a handsaw, apply force when pushing and relax when pulling. The material is secured in a vise.

4. Foot-Pedal Cutting Machine

A foot-operated cutting machine is used to cut steel plates less than 1 mm thick and aluminum alloy plates less than 2 mm thick. The cutter can cut by simply aligning the injured plate with the blade and pressing down hard on the pedal. The foot pedal cut-off machine is used for cutting in a straight line.

5. High-Speed Cut-off Machine

The high-speed cut-off machine cuts materials with a grinding stone of about 5 mm in thickness that rotates at high speed. It can quickly cut materials with thin walls, such as steel pipes and angle materials.

6. Gas Cutting

In gas cutting, steel materials are melted and cut by the combustion heat of acetylene gas and oxygen. Beginners may find that the cut surface is bent and quality cannot be ensured. Also, a qualification is required to perform gas cutting.