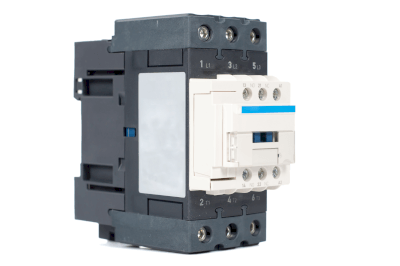

What Is a Contactor?

Contactors, also called electromagnetic contactors, are a type of control device called a plunger relay.

A plunger relay is a type of control device called a plunger relay, which is cylindrical and has a movable part with a spring mechanism. Inside the cylindrical electromagnetic coil is a movable iron core that acts as a relay, and the movement of the iron core controls electrical on/off.

Plunger-type relays are characterized by the large open/close capacity of their electrical contacts and excellent dielectric strength. Taking advantage of these features, they are often used as control devices to turn on and off equipment that uses large currents.

In addition to electromagnetic contactors, plunger-type relays include electromagnetic switches, which are also called magnet switches. Electromagnetic switches are composed of a contactor and a thermal relay.

Uses of Contactors

Contactors are used in a variety of electrical equipment for the purpose of interrupting or connecting electrical circuits that handle large amounts of power, such as interrupting electric circuits, opening and closing heaters, and turning motor current on and off.

Many of these devices carry relatively large currents, and their uses include electric industrial equipment, various vehicles including EVs, ships, and airplanes. Since the contact points are contacted electromagnetically, they can be driven by a small operating current and can control and operate large currents.

The most significant feature of contactors is that they can be switched on and off by electrical signals, rather than manually on and off via the human hand.

Principle of Contactors

The principle of contactors is they switch the contacts of an electrical circuit in accordance with the mechanical contact of an iron core, which is operated (like an electromagnetic relay) by the force of the magnetic field generated by the current flowing in an electromagnet coil.

In general, a contactor consists of a contact part, an electromagnet part, and an external connection part.

1. Contact Section

The contact part creates a state of electrical continuity or non-conductivity through mechanical contact.

2. Electromagnet

The electromagnet section generates a magnetic field with an electromagnetic coil and brings the movable iron core into contact with the fixed iron core.

3. External Connection

The external connections include terminals that connect to the outside of the contactor.

The principle of opening and closing the contactor is the same as that of an electromagnetic relay, in which the fixed iron core acts as an electromagnet to attract the movable iron core. When the coil does not operate, the spring force causes the movable iron core to return to its original position, returning to an electrically non-conductive state. This action creates an electrically conductive or non-conductive state.

Contactor terminals can be broadly classified into three types: main contacts, auxiliary contacts, and coils.

- Main Contact

A terminal that connects to a load, etc. - Auxiliary Contacts

Auxiliary contacts are used to communicate the contactor’s operating status, etc., to the control unit. - Coil

This terminal is connected to the coil that operates the electromagnetic contactor.

Other Information on Contactors

1. Difference Between Breakers, Contactors, and Magnetic Switches

Breakers, as used in ordinary households, are used for high current (tens of times the rating or more) protection or to protect circuits when overcurrents exceeding the rating continue to flow. It is the on/off operation of the electric circuit for this purpose, and can also be turned on and off manually.

Contactors, on the other hand, do not have a manual on/off function and operate only on electrical signals. In addition, contactors generally do not have a protective function and cannot handle high currents in the event of a short circuit that greatly exceeds their rating.

A magnet switch consists of a contactor and a thermal relay. The major difference between a magnet switch and a contactor is that a magnet switch has an overload protection function via a thermal relay to protect a motor, for example. However, unlike breakers, most of them cannot handle instantaneous high current in the event of a short circuit.

2. Contactors for EVs

Contactors are also used in the motor control section of EVs and other electric vehicles, but they have features unique to EVs.

First, to ensure high reliability for in-vehicle applications, special gases such as hydrogen gas are sealed in the movable contact points of contactors to prevent deterioration in reliability over time due to oxidation of the contacts.

Some manufacturers are also developing and commercializing robust structural designs that can withstand the shocks and vibrations inherent to EVs, as well as special electromagnets that accommodate the reversed polarity differences unique to EVs during arcing caused by charging and discharging of EVs.