What Is an Ultrasonic Metal Joining Machine?

Ultrasonic metal joining machines are machines that use air vibrations generated by ultrasonic waves to join metals together.

Normally, heat is used to melt metals when joining metals, but ultrasonic metal joining machines do not use heat. Ultrasonic joining machines, however, do not use heat. Ultrasonic waves cause metal atoms to vibrate, making it possible to join metals with different melting points.

On the other hand, the disadvantage is that the joining strength is weak because the metal is not melted once and then joined completely, as is the case with heat. Therefore, care must be taken when seeking high strength.

Metal joining can be broadly classified into three categories. Specifically, there are three types of metal joining: fusion welding, in which the joint is heated and melted; solid phase welding, in which mechanical pressure is applied to cause plastic deformation of the joint; and brazing, in which a solder material with a low melting point is applied to the joint. Ultrasonic bonding is classified as solid phase bonding.

Uses of Ultrasonic Metal Joining Machines

Ultrasonic metal joining machines are used to join items that should not be affected by their surroundings, such as foil lamination of battery electrodes and joining copper wires to connector terminals. Ultrasonic Metal Joining Machines do not melt metal with heat, so the material itself is not subjected to intense heat.

Therefore, there is little effect of heat on other parts of the joint. However, since the connection strength is not high, it is not suitable for large moving parts.

Principle of Ultrasonic Metal Joining Machine

When metals are exposed to air, an oxide film is formed on the surface or foreign matter adheres to the surface. When these materials are adhered, joining is not possible unless the bonding surface is melted once.

However, when ultrasonic vibrations are applied parallel to the bonding surface while pressure is applied vertically to the metal, the ultrasonic vibrations cause the metals to rub against each other, peeling off the oxide film and adhesions to expose the metal surface. The interatomic force enables atoms to bond to each other without melting the metal.

Once the metal is melted, if the metal surface is thin, the shape itself may be deformed or shrink. However, with ultrasonic metal joining, the force acts on only a small layer of the joining surface, so the shape is not greatly disrupted.

Also, since only ultrasonic energy is used, no gas is consumed. The consumption of electrical energy is also greatly reduced, making it an environmentally friendly joining method.

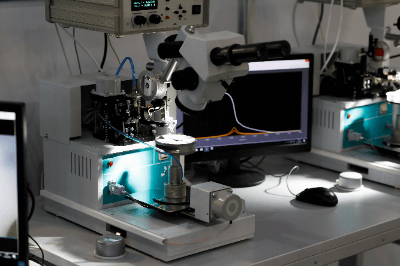

Structure of Ultrasonic Metal Joining Machine

Ultrasonic metal joining machines consist of an oscillator, a vibration unit, and an ultrasonic horn.

1. Oscillator

It provides high-frequency power and controls the frequency. Since the frequency varies with each ultrasonic horn used and fluctuates depending on the temperature and pressure conditions during operation and operation, a frequency tracking circuit is included to adjust the frequency to the optimum level.

2. Vibrating Section

The vibration section consists of a transducer and a fixed horn. The frequency sent from the oscillator is transmitted through the transducer to the fixed horn, which amplifies the amplitude.

3. Ultrasonic Horn

In the ultrasonic horn, the ultrasonic vibration from the vibrating section and the applied pressure cause instantaneous frictional heat on the workpiece joining surface, which melts the contact surface of the workpiece and bonds the molecules to each other. When the ultrasonic vibration stops, the molten workpiece rapidly cools and solidifies.

If pressure is applied continuously during cooling, the bonded surfaces will solidify in a denser state, resulting in a stronger bond.

Ultrasonic Metal Joining Machine Features

Ultrasonic metal joining machines are safer, quicker, and more accurate than other joining methods. Joining by ultrasonic waves is a spot joining process, which allows for precise processing. In addition, it takes only a few seconds to join.

Except for the spot portion, there is little effect on the metal, and damage or deformation is unlikely to occur. Due to solid phase bonding by ultrasonic waves, the temperature rise to the base metal is slow, and bonding is possible at a relatively low temperature of 35% to 50% of the base metal’s melting temperature.

Therefore, there are no sparks or smoke, and excellent strength and conductivity can be ensured.