What Is a Spray Nozzle?

A spray nozzle is a device that sprays out a liquid or gas at once by specifying the direction in which the liquid or gas is to flow.

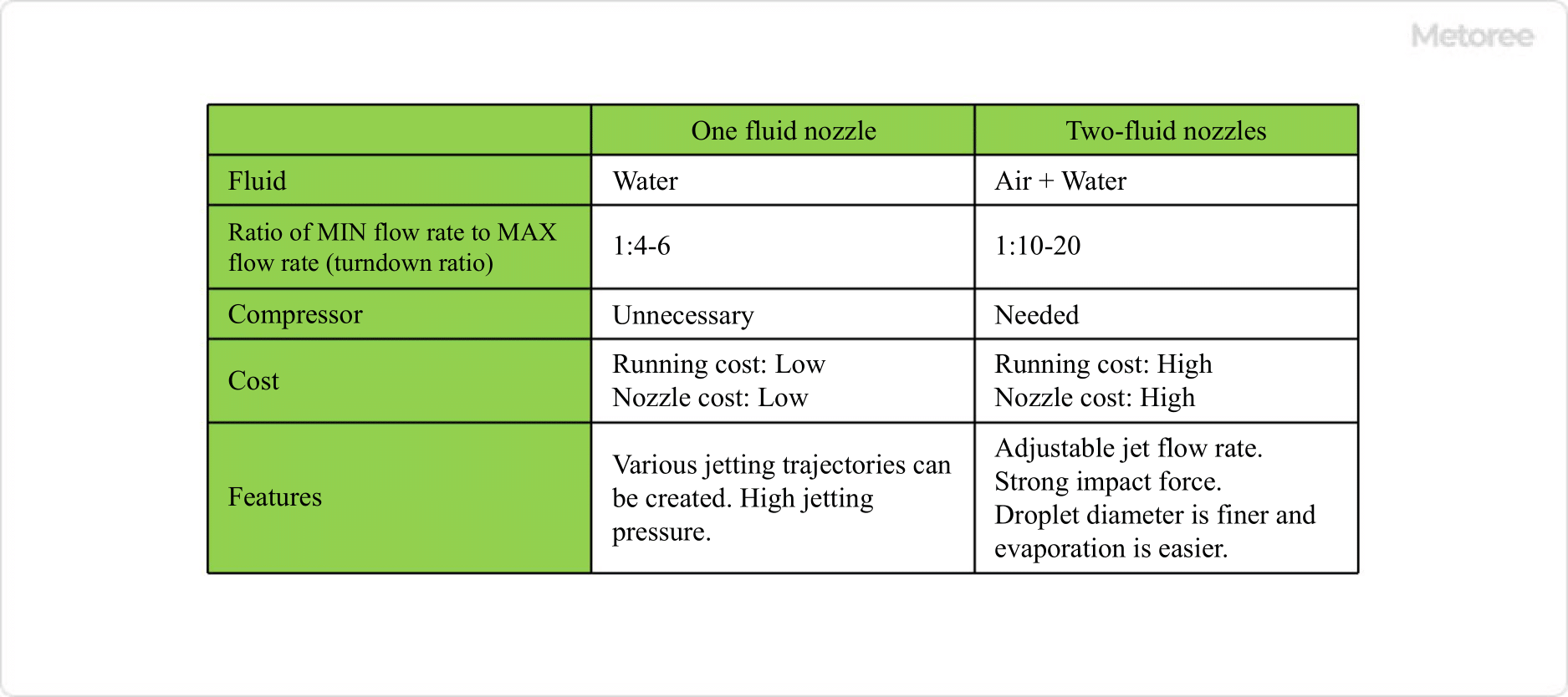

Spray nozzles can be used not only to eject liquids but also to eject gases and are called air nozzles. On the other hand, there are two types of spray nozzles for liquids: one-fluid nozzles and two-fluid nozzles.

One-fluid nozzles are spray nozzles that use only the pressure applied to the liquid to eject the liquid, while two-fluid nozzles are spray nozzles that use a mixture of liquid and compressed air to pulverize the liquid and eject it.

Uses of Spray Nozzles

Spray nozzles are used in a variety of industrial, industrial, and household applications, as they refer to all devices that eject liquids or gases according to the desired spray pattern. The most familiar product that uses a spray nozzle is a “mist sprayer.”

Other functions include humidifying liquids by turning them into fine particles and diffusing them, and applying liquids evenly. Spray nozzles for gases, on the other hand, can be used to spray air at the desired pressure, so they can be used to spray bacteria and invisible debris with an air shower, or to blow off or cool scraps from cutting.

Principle of Spray Nozzles

Figure 1. Comparison of one- and two-fluid nozzles

1. 1-Fluid Nozzle

The one-fluid nozzle lifts the liquid up to the spray nozzle by applying pressure to the liquid. Another major advantage of this system is that it does not require a compressor, and can be easily used as long as a liquid supply facility is available.

Therefore, if you want to change the spray trajectory according to the situation, a one-fluid nozzle is recommended. However, it also has the disadvantage of not being able to apply a small amount of liquid because of the high pressure required for it to function as a spray nozzle.

2. 2-Fluid Nozzle

Two-fluid nozzles use not only pressure but also the force of air currents to eject liquid, enabling atomization of liquid at a lower pressure than with one-fluid nozzles. In addition, a wide range of liquid jet flow rates can be achieved.

Therefore, a two-fluid nozzle is better suited for jetting liquid at low pressure or for producing finer particles from the jet. However, compressed air is required in addition to the liquid pump, so a compressor and other equipment must also be provided.

Another disadvantage is that the nozzle also has a complex structure, making it more costly.

How to Select a Spray Nozzle

When selecting a spray nozzle, it is important to confirm the following points:

1. Confirmation of Equipment

First, before selecting a spray nozzle, check the specifications of the equipment. The pressure and flow rate that can be supplied to the spray nozzle are determined by the performance of the pump that pumps the liquid, the diameter and length of the piping, and the pressure of the compressed air.

It is also necessary to confirm whether there is enough space for the spray nozzle to be installed, and whether the spray nozzle will fit into the equipment. In addition, it is also necessary to check how far away the spray nozzle can be from the object to be applied.

2. Confirmation of the Environment

Next, check the operating environment. It is necessary to check the strength, heat resistance, and materials that will not wear out due to the ambient temperature, viscosity and surface tension of the liquid to be used, and internal pressure.

In addition, if the liquid contains solids or other substances, or if the temperature is high, the spray nozzle may become clogged. Knowing the size of the solid content may make it possible to select a spray nozzle that takes into account the minimum passage diameter inside the spray nozzle.

3. Determination of Spray Nozzle Specifications

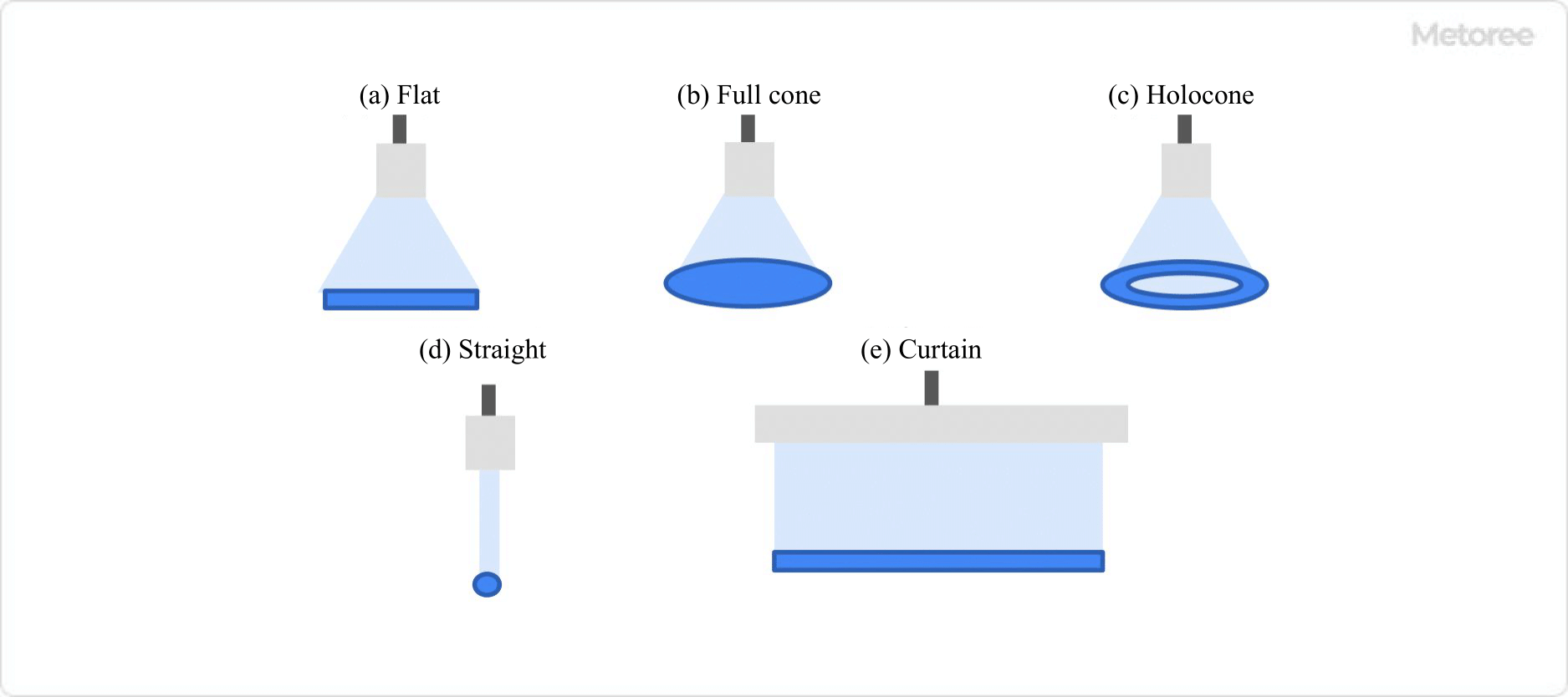

Figure 2. Spray nozzle pattern shape

In order to achieve the objective, confirm what pattern of application is needed, how much flow rate is required, how wide a range of discharge is needed, and how much variation in application volume can be tolerated.

Spray pattern shapes include flat, full cone, holocone, straight, and curtain. Refer to the spray nozzle catalog and select the appropriate nozzle for the spray pattern.

Other Information on Spray Nozzles

Spray Nozzle Application Properties

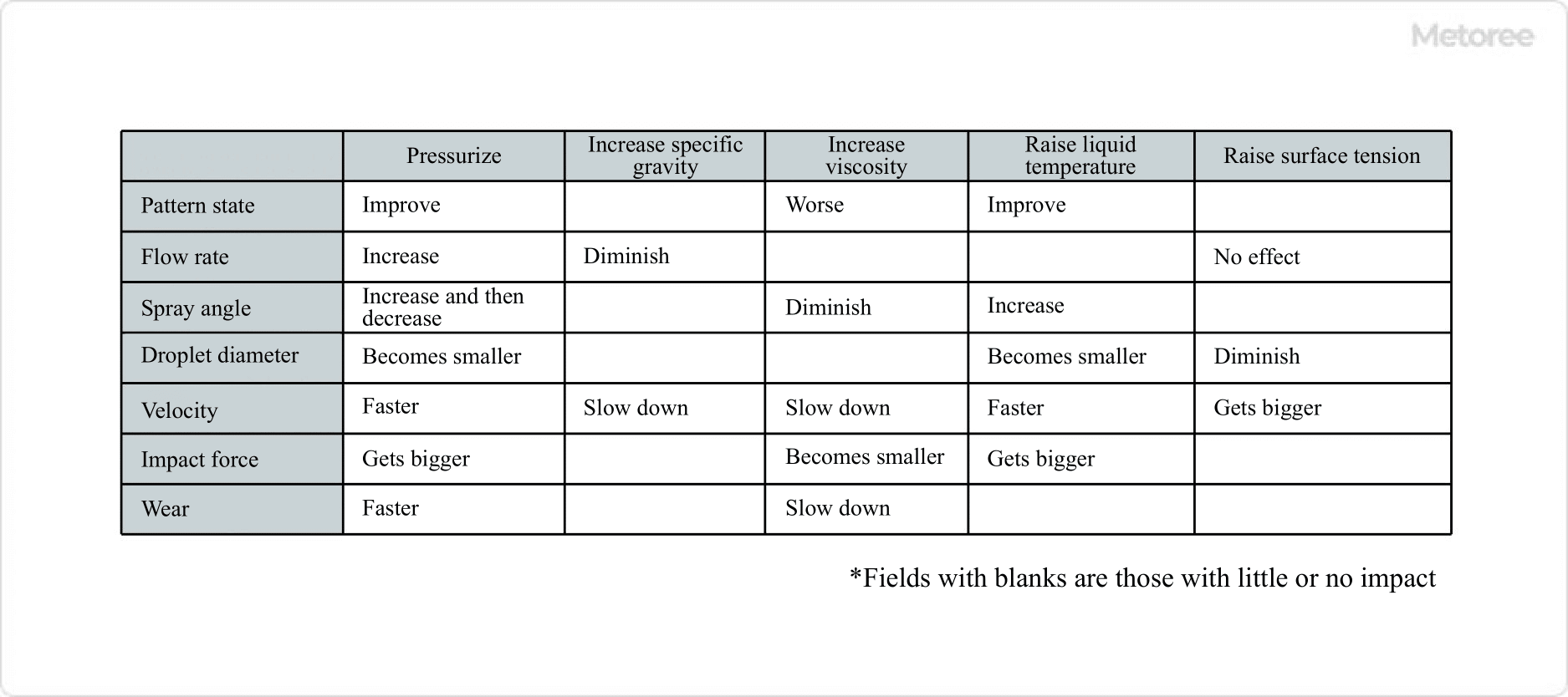

Figure 3. Change in application properties of spray nozzle

After determining the type of spray nozzle, check the flow rate and angle at a given pressure. It is important to note that there are differences in the change in spray angle and other characteristics when the pressure is changed according to each pattern.

In general, the higher the injection pressure, the wider the spray angle. However, for full-cone nozzles and other nozzles containing cores, the angle may widen up to a certain pressure, and narrow at higher pressures.