What Is a Roller Bearing?

A roller bearing is a type of rolling bearing that uses rollers as rolling elements.

The rolling elements are the parts of the bearing that rotate between the inner ring and outer ring (raceway) or raceways. Ball bearings are the most commonly used type of rolling bearing, but they differ significantly in that they use rollers (cylindrical parts) instead of balls as the rolling elements.

Roller bearings are used to support a rotating shaft that is subjected to heavy loads. The contact between the rolling elements and the inner and outer rings and raceways, as described below, is point contact in a ball bearing, whereas it is linear contact in a roller bearing. Since the contact area increases from a point to a line, a larger load can be supported.

Uses of Roller Bearings

Roller bearings are incorporated into a wide variety of industrial machinery. Specific applications include rotating parts in automobiles, rail vehicles, aircraft, construction machinery, wind turbines, and industrial robots.

Roller bearings can support higher loads than ball bearings and have higher support rigidity. On the other hand, ball bearings have an advantage in rotational performance. When a low load and high rotation is required, ball bearings offer lower rolling resistance. Because of these characteristics, ball bearings are often used in gearboxes of industrial machinery.

In automobiles and industrial machinery, helical gears are often used, where the gear teeth are aligned at an angle to the axis of rotation, resulting in lower noise and vibration. However, the oblique nature of the gears will result in large forces acting in three directions. Roller bearings are used to support these shafts.

Principle of Roller Bearings

There are two main types of roller bearings: radial roller bearings and thrust roller bearings. Each has a different structure, but the principle is the same.

The rollers roll between the two parts in which they are sandwiched, allowing the bearing to rotate smoothly while taking the large load generated on the rotating shaft. The surface of each part is finished to be hard and is less uneven, i.e., to have a small surface roughness. Heat-treated alloy steel is often used.

Structure of Roller Bearing

1. Radial Roller Bearing

It consists of an inner ring, outer ring, rollers, and retainer. The rollers are placed between the outer diameter face (raceway) of the inner ring and the inner diameter face (raceway) of the outer ring. Retainers are used to keep the rollers at an equal distance and to prevent excessive friction due to contact between the rollers.

2. Thrust Roller Bearing

The three parts are integrated, the rollers and retainers are integrated with one of the raceways, or all three are separate. The choice of integral or separate construction is determined by factors such as ease of assembly.

Types of Roller Bearings

There are several types of roller bearings, in addition to radial and thrust roller bearings. The two types are the open type, which is externally lubricated, and the sealed type, in which grease is sealed inside the bearing.

By keeping each rolling surface properly lubricated, the bearing continues to roll while an oil film exists on the outer diameter surface at each raceway. Therefore, even under high-load and high-speed operating conditions, frictional resistance is low and smooth operation for a long period is possible.

When classified according to the shape of the roller, they can be divided into the following four categories.

1. Cylindrical Roller Bearing

Cylindrical roller bearings have simple cylindrical rollers. Radial roller bearings support only radial loads, while in contrast, thrust roller bearings support only axial loads.

2. Needle Roller Bearings

A needle roller bearing is a roller bearing whose rollers are as long and narrow as a needle. Needle roller bearings are also called needle bearings. Although there are ISO specifications for this type of roller bearing, needle roller bearings are also referred to as bearings that fall outside the scope of these specifications.

3. Tapered Roller Bearings

Tapered roller bearings are mainly used as radial roller bearings. They are also called tapered roller bearings. Because the rolling elements are tapered, they can support loads perpendicular to the axis and axial loads in a fixed direction.

When used in two or more rows, it can support axial loads in either direction in the axial direction and can also take high moment loads. It is often used to support helical gears.

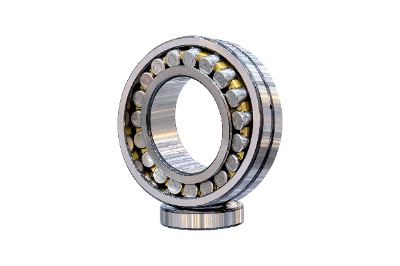

4. Spherical Roller Bearings

In spherical roller bearings, the rolling elements have a sag shape (cylindrical shape with a convex center). Furthermore, when the outer ring raceway is concave and the rollers are in alignment with the inner ring raceway, the circumference of the rolling elements is convex in line with the outer ring raceway.

Therefore, even if the center of rotation between the outer ring and inner ring is inclined, the inclination can be tolerated. It can support loads perpendicular to the shaft and axial loads in both directions.

Other Information About Roller Bearings

Precautions for Using Roller Bearings

Roller bearings are used especially for rotating shafts that must support large loads. When used, it is important to ensure sufficient rigidity in the inner and outer rings and raceways.

The bearing surface of the housing that supports these parts must also be sufficiently rigid. If the surface on which the rollers roll has low rigidity, the rollers will not make linear contact as designed and localized contact will occur. In such cases, the contact surface pressure will be high, and the life of the roller may reach its end earlier than expected in the design.

In addition, it is important to ensure sufficient lubrication, to ensure that the lubrication provides sufficient cooling effect, and to remove foreign matter such as iron powder from the operating environment, including lubricating oil, by means of oil filters or magnets.