What Is a Conductive Mat?

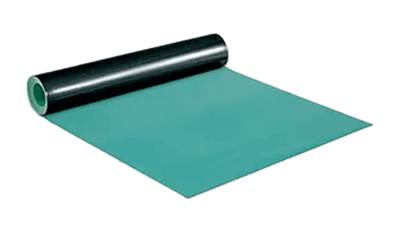

Conductive mats are used to discharge static electricity gradually that has been charged on the human body.

They are often laid on the floor and used in workshops, factories, laboratories, and clean rooms. In some cases, durability and abrasion resistance are required, and regular maintenance is necessary.

Uses of Conductive Mats

Conductive mats are made of conductive materials and are used to discharge static electricity, seal electromagnetic waves, and prevent damage to equipment caused by static electricity.

1. Prevention of Static Electricity

Conductive mats are placed on floors to reduce the risk of static electricity generation and discharge. They are especially used in workshops, factories, and clean rooms to facilitate the discharge of static electricity from people and equipment.

2. Electromagnetic Shielding

Conductive mats are placed around electronic and precision equipment to block the entry of electromagnetic waves from the outside. This protects the proper operation of the equipment and reduces electromagnetic interference (EMI) problems.

3. Explosion-Proof Environment

Conductive mats may be used in potentially explosive environments. In areas where explosive gases or vapors are present, the generation and discharge of static electricity must be suppressed. Conductive mats can reduce the risk of ignition due to electrical discharge.

4. Prevention of Electric Shock

Conductive mats, when connected to the ground or grounding system, provide a safe grounding condition for people and equipment. Secure grounding improves safety by reducing the risk of electric shock and equipment failure.

5. Laboratory or Clean Room

Conductive mats may also be used in certain environments, such as laboratories and clean rooms. In environments where static control and electromagnetic shielding are important factors, conductive mats can be expected to play a part.

Principle of Conductive Mats

Conductive mats promote the discharge of static electricity by means of conductive materials. The following is a brief description of the principle of conductive mats.

1. Conductive Material

Conductive mats are typically made of conductive materials. These materials include conductive fibers, conductive rubbers, and conductive polymers. The resistivity of these materials is generally around 10-6 Ωm to 10-4 Ωm, which is one to three orders of magnitude greater than that of iron.

Since a small resistance value is dangerous due to the large electric current that flows when static electricity is discharged, we dare to use materials with a larger resistance value. Conductive mats have conductive materials woven into their surfaces and interiors, and electric charges and currents flow to ground through these materials.

2. Electrostatic Discharge

Conductive mats serve to facilitate the discharge of static electricity from charged objects. Static electricity builds up (is charged) on objects and the human body, but is quickly discharged when it comes into contact with the conductive material woven into the conductive mat.

3. Connection to Earth

Conductive mats are effective when connected to the ground or the grounding system. Static electricity (charge) on a person or object flows to the ground through the ground wire the moment it touches the conductive mat.

As described above, the effect of conductive mats is due to the conductive material’s ability to conduct electricity and discharge static electricity. This allows the mats to achieve their intended purposes, such as static electricity suppression, safety improvement, and electromagnetic shielding.

How to Choose a Conductive Mat

There are several types of conductive mats available, but the following factors should be considered in selecting the appropriate conductive mat

1. Type of Conductive Material

Conductive materials used for conductive mats vary widely, with conductive fibers, conductive rubbers, and conductive polymers being the most common. Depending on the application and requirements, the properties of the material (durability, antimicrobial properties, heat resistance, etc.) should be taken into consideration when selecting the appropriate material.

2. Electrical Performance

The electrical performance of conductive mats is also important. The resistivity of the material should be checked and its ability to discharge static electricity and grounding should be considered.

3. Size and Shape

Conductive mats come in a variety of sizes and shapes, and the appropriate size should be selected to suit the work space and installation location. There are also types that can be cut on site and can be processed into appropriate shapes to suit the installation environment.

4. Durability and Maintainability

The durability of conductive mats is also important. If abrasion or chemical resistance is required, a mat with corresponding durability should be selected. It is also important to select mats that can be easily cleaned and regularly inspected based on ease of maintenance.

5. Standards and Regulatory Requirements

Certain industries and environments may have specific standards or regulatory requirements for conductive mats (e.g., regulations, fire codes, etc.). Please review applicable standards and requirements and select mats that comply with them.