What Is a High Precision Thermometer?

A high precision thermometer is a precision temperature measuring instrument that can measure temperature with the highest precision of any thermometer.

A high precision thermometer is a precision temperature measuring instrument that can measure temperature with the highest precision of any thermometer.

It is used together with a temperature sensor. By using a thermometer and a temperature sensor together, accurate temperature measurement is possible. Therefore, they are used to adjust temperatures and calibrate thermometers.

Thermoelectric sensors and resistance thermometer sensors are used as temperature sensors, each of which has different characteristics, so it is important to select a temperature sensor suitable for the intended use.

Uses of High Precision Thermometers

High precision thermometers are used to calibrate thermometers. By using a combination of temperature sensors, the temperature is adjusted to confirm that the calibration temperature of the thermometer in everyday use is correct. However, high precision thermometers are more expensive than ordinary thermometers, and their large size makes them less convenient to use.

The correct temperature data, pre-calibrated by the temperature sensor, is stored in memory, or in external memory for those types of high precision thermometers that do not have built-in memory. By reading the data in this memory, measurement with high accuracy can be made.

Principle of High Precision Thermometers

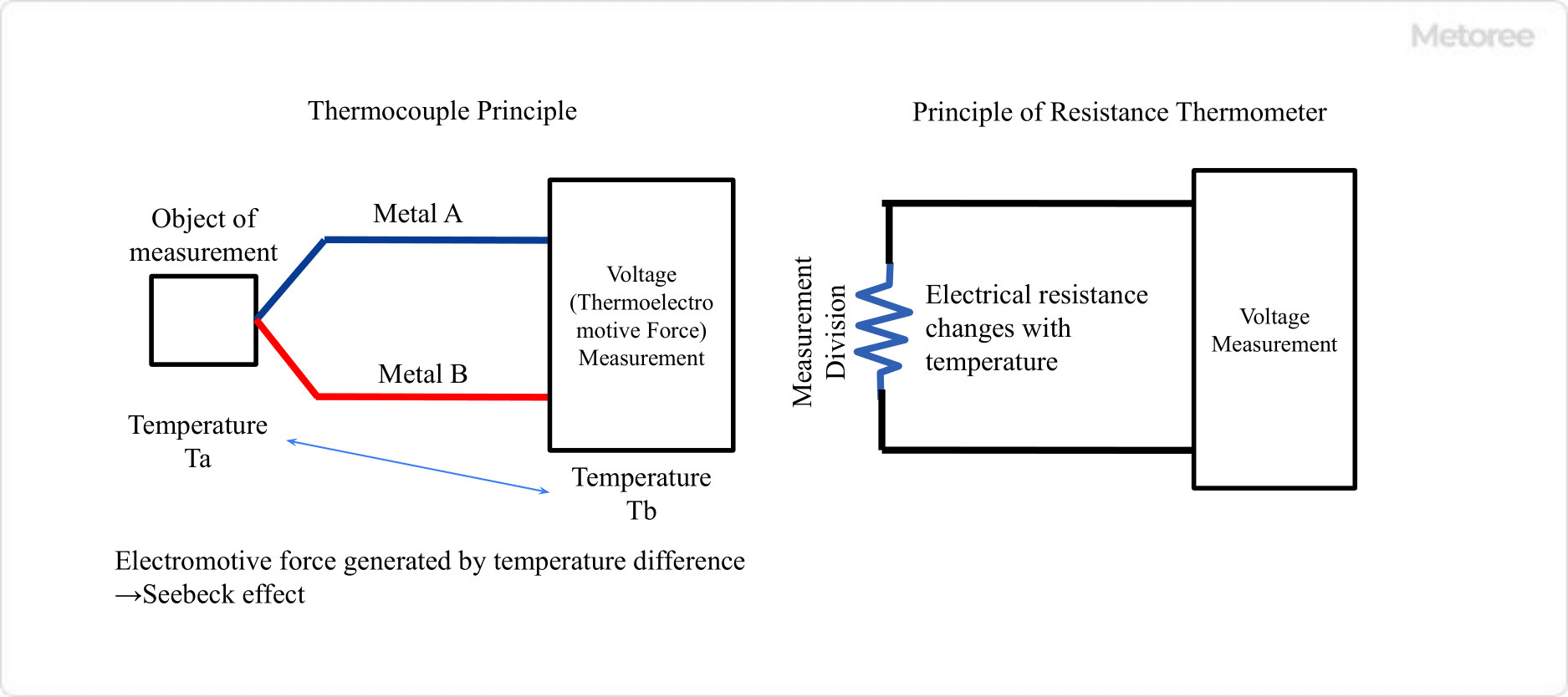

Figure 1. Principle of thermometers

The most commonly used temperature sensors in the industry are thermocouples and resistance thermometers.

1. Thermoelectric Temperature Sensor

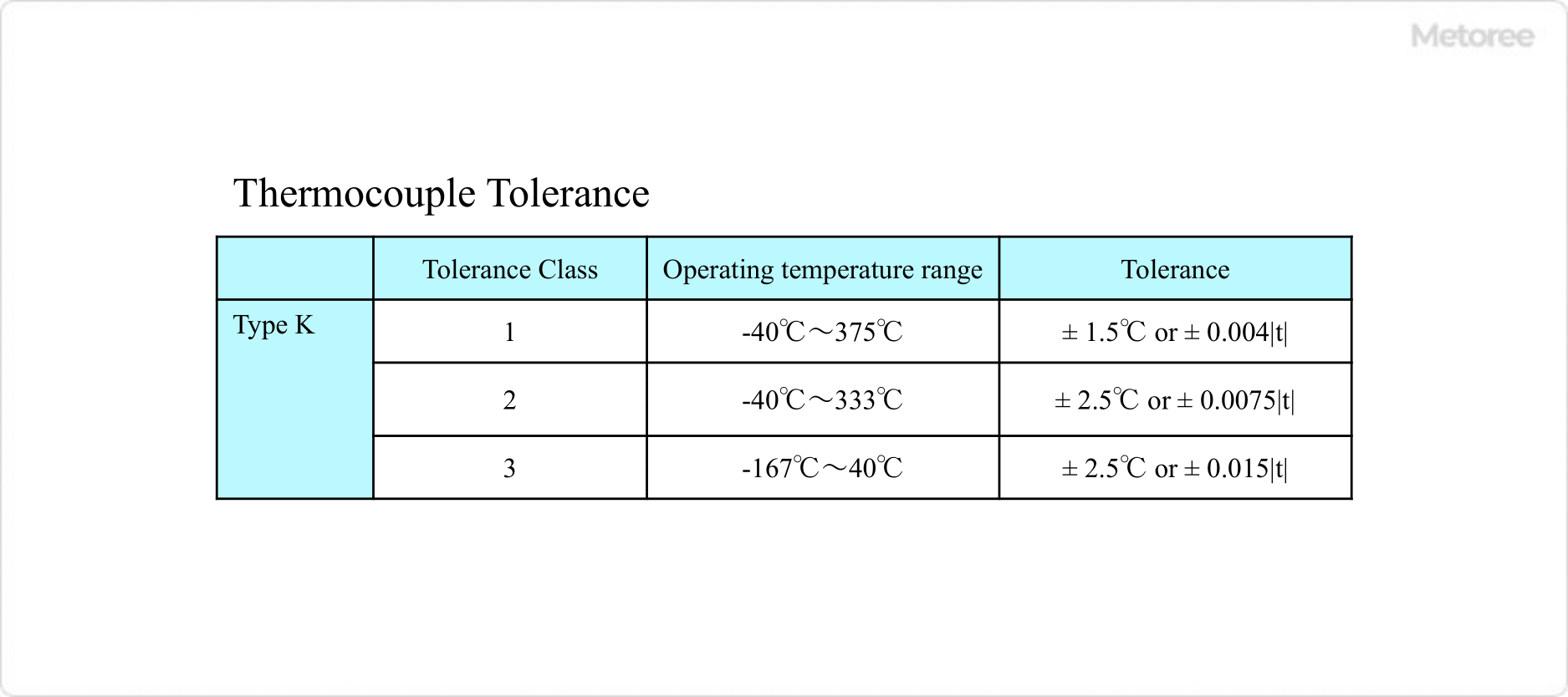

Figure 2. Thermocouple Temperature Tolerance

A thermoelectric temperature sensor is a temperature sensor that combines two different types of metal conductors. When a temperature difference occurs at the contact points of the different metals, a voltage is generated between the metals, and the Seebeck effect, which generates a thermoelectromotive force, is used to measure the voltage, thereby accurately measuring the temperature.

The characteristics of the thermocouple are its fast response and the ability to measure even at high temperatures due to its small size. It is often misunderstood that only the tip of the thermocouple (the part where the different metal wires are bonded) is the measurement part, but since the electromotive force generated between the different metal wires is the target of measurement, the temperature difference including the conductor part is important. The temperature tolerance is larger than that of the resistance thermometer.

2. Temperature Sensor Using Resistance Thermometer

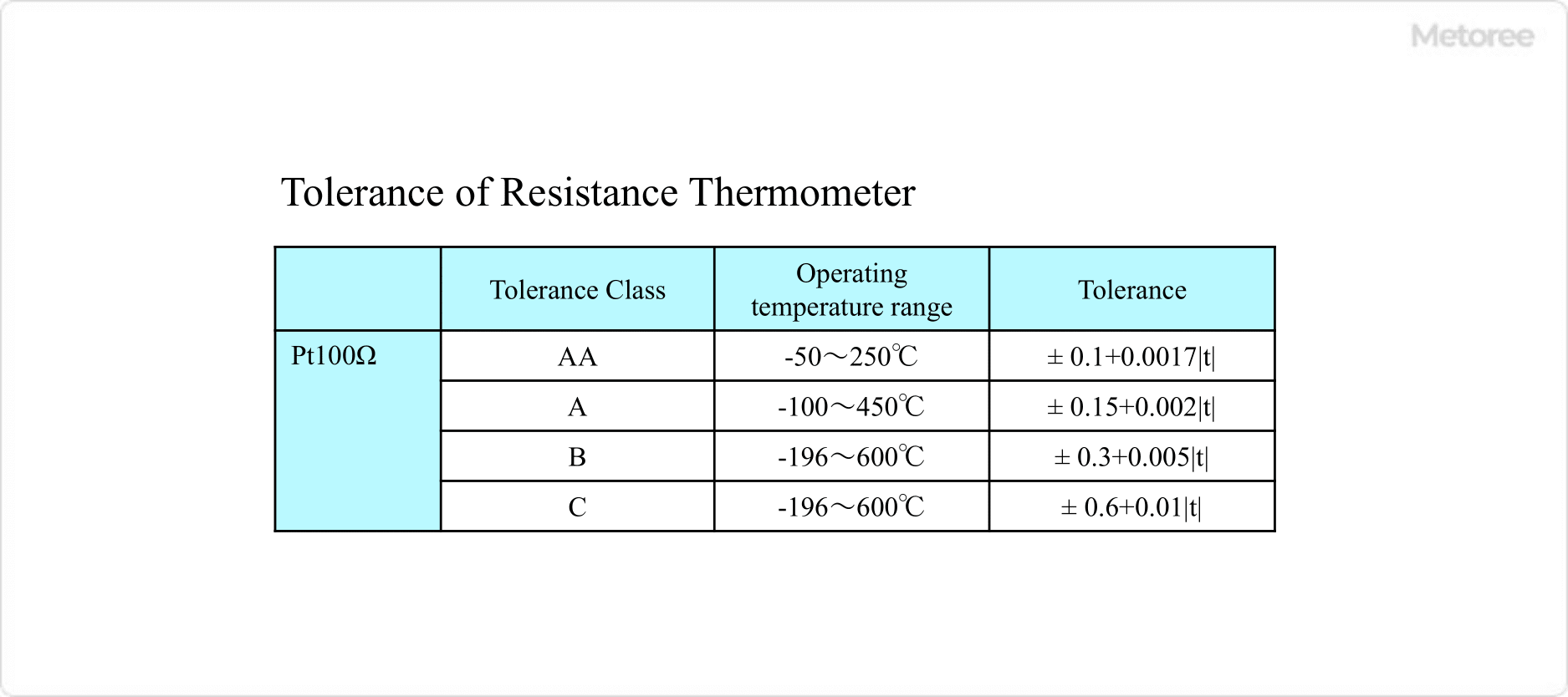

Figure 3. Resistance Thermometer Tolerance

Temperature sensors using resistance thermometers are based on the principle of the electrical resistance of metals increasing as the temperature rises. Highly pure platinum or nickel is used as the material for the strands.

Compared to thermoelectric, they cannot be used at high temperatures and have a narrower coverage range. However, it is characterized by its ability to detect temperatures with very high accuracy in the low to medium temperature range and its high stability.

High precision thermometers are similar in principle to ordinary thermometers, but they use a higher class of thermometer, and their accuracy is maintained through thorough calibration and other measures.

Other Information on High Precision Thermometers

1. Measurement Error of High Precision Thermometer

No matter how strictly calibrated the specifications are, if the measurement is not appropriate for the environment, the correct temperature cannot be measured. Typical error factors are as follows.

Error Factors for Resistance Thermometers

- Effect of self-heating due to energizing current

- Influence of thermal shock due to temperature change of measurement object

- Effects of vibration and shock

Other factors include the effects of abnormal voltages and currents (e.g., lightning strikes, high-voltage discharges, etc.) and the effects of low insulation resistance.

2. Error Factors of Thermocouples

Error factors for the most commonly used K-type thermocouples are as follows:

Oxidation in a Reducing Atmosphere

When K-type thermocouples are used in a high-temperature reducing atmosphere between 800 and 1,000°C, the measured value may deviate by several hundred degrees. This is because the surface oxide film of the chromel wire used on the + side of the K-type thermocouple is reduced by the reducing atmosphere and then oxidized to form NiCr2O4. In particular, hydrogen gas permeates through some metal protection tubes at high temperatures, so it is important to use a sheath material with low hydrogen permeability.

Effect of Sheath Mid-Temperature (Shunt Error)

If the sheath is in contact with a hotter part than the temperature to be measured, the temperature will be higher than the part to be measured. This is because the insulation resistance of the inorganic filler inside the sheath decreases at temperatures higher than 800°C. It is effective to pay attention to the installation method and select a sheath with a larger outer diameter to increase the insulation distance between strands.

Inevitable Error of K-Type Thermocouples (Short Range Ordering)

When K-type thermocouples are used at temperatures between 300 and 550°C, the EMF characteristics may change and errors may occur. This is because the metallurgical structure of the chromel alloy increases EMF at temperatures between 300 and 550°C. Heating to 650°C or higher will restore the original characteristics.

External Electrical Influences

Noise generated by generators, motors, etc. can cause errors. To minimize the effect of noise, use shielded compensating conductors. If a shielded compensating conductor is not used or a two-point grounding type is used, the shielding effect may be reduced or induced currents may be picked up instead.

Effects of Not Using Compensating Conductors

Thermal thermocouples do not measure the temperature at the tip, but rather the “temperature difference” between the tip and the area connected by a conductor, which is the electromotive force. Therefore, the part of the thermocouple that is connected to the conductor is the electromotive force generating part. However, if thermocouple wires are used for the entire measurement, the cost will be high and the resistance value will be too high, so compensating conductors are used.

A compensating conductor is a conductor that has almost the same EMF as the thermocouple used in combination. Sometimes the principle of the thermocouple is misunderstood and an ordinary conductor is used instead of a compensating conductor, or the conductor that should be used is mistaken.

In addition, both resistance thermometers and thermocouples are used to measure temperatures by making contact, so care must be taken with the method of contact and the external ambient temperature.