What Is Rust-Proof Paper?

Figure 1. Image of anticorrosion paper

Rust-proof paper is a wrapping paper with a rust-preventive function.

Rust-proof paper is manufactured by coating or impregnating kraft paper with a vaporizable chemical substance (rust-proofing agent) that prevents rust (corrosion) of metals. By simply wrapping the metal or other product to be protected from rust with rust-proof paper, the object can be easily protected from rust.

The paper can be freely transformed according to the size and shape of the object, and can be easily used for everything from simple wrapping to sealed packaging.

Uses of Rust-Proof Papers

Rust-proof paper is used to protect and preserve objects from rust for a long period, for example, when the object is made of rust-prone materials or in an environment where rust is likely to occur. It is used in industries that handle metals, such as steel and automobiles, where rust can cause quality problems.

Rust-proof paper with a barrier layer and moisture-proofing properties is also commercially available, and when using such rust-proof paper, moisture-proof packaging is not necessary. In addition to direct wrapping, the paper can be placed in a sealed space, such as a polyethylene bag or a moisture-proof cardboard box, to prevent rust.

Principle of Rust-Proof Papers

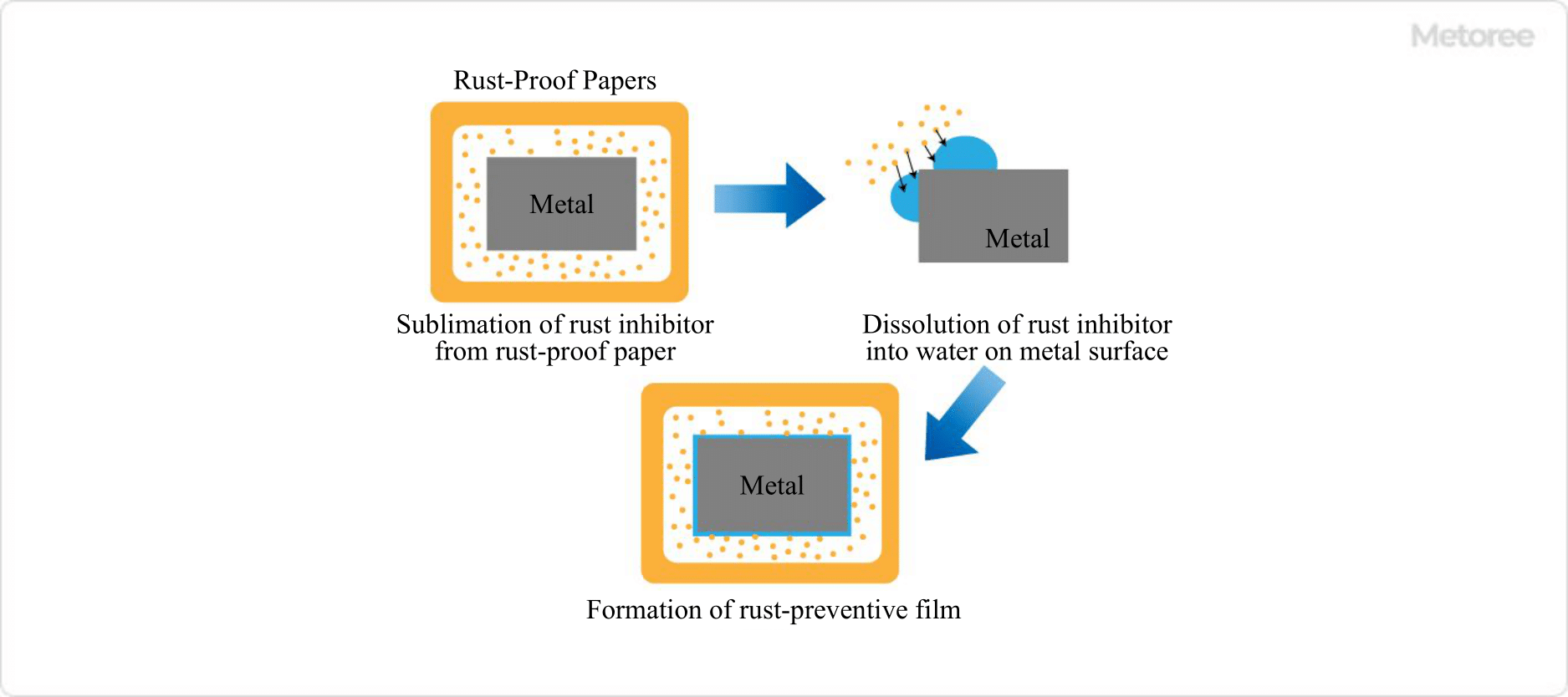

Figure 2. Principle of anti-rust paper

Rust-proof paper prevents rust through a chemical action. When the rust inhibitor vaporized from rust-proof paper is adsorbed on the metal surface, it exerts its rust-preventing effect. The principle of how rust-proof paper prevents metal from rusting is as follows:

- The rust-proof paper gradually vaporizes (sublimates) at room temperature, and the vapor quickly fills the sealed space between the paper and metal.

- The vaporized rust inhibitor dissolves in the moisture on the metal surface. The dissolved rust inhibitor is physically and chemically adsorbed as molecules or ions to form a “rust inhibiting film.

- The rust-preventive film shields the steel from the outside air, which causes rust, and prevents it from changing into rust.

The rust-preventive film of this vaporizable rust-preventive agent is extremely thin, on the nanometer order of thickness, and has weak adsorption power, so it does not cause any change in the appearance of the metal surface. After rust-preventive packaging, metal products can be used immediately without cleaning the surface. In addition, because it is a rust inhibitor that uses vaporization, it is expected to have an immediate effect.

Rust-proof paper uses a chemical reaction, so unlike rust-preventive oil, which prevents rust through physical action, it cannot be expected to have the same effect on all metals, which can be considered a disadvantage. It is important to select the most suitable rust-proof paper for the product to be packaged.

It is also necessary to clean the product to be packaged before wrapping it in rust-proof paper. Rust-proof paper does not remove dirt, so it may be difficult for the rust inhibitor to reach the product if dirt remains on the paper.

Types of Rust-Proof Paper

Rust-proof paper can be classified in two ways: by the metal to be rust-proofed, i.e., the rust-proofing agent component, and by the packaging form, i.e., the base packaging paper part.

1. Classification by Rust-Preventive Metals/Rust-Preventive Agent Components

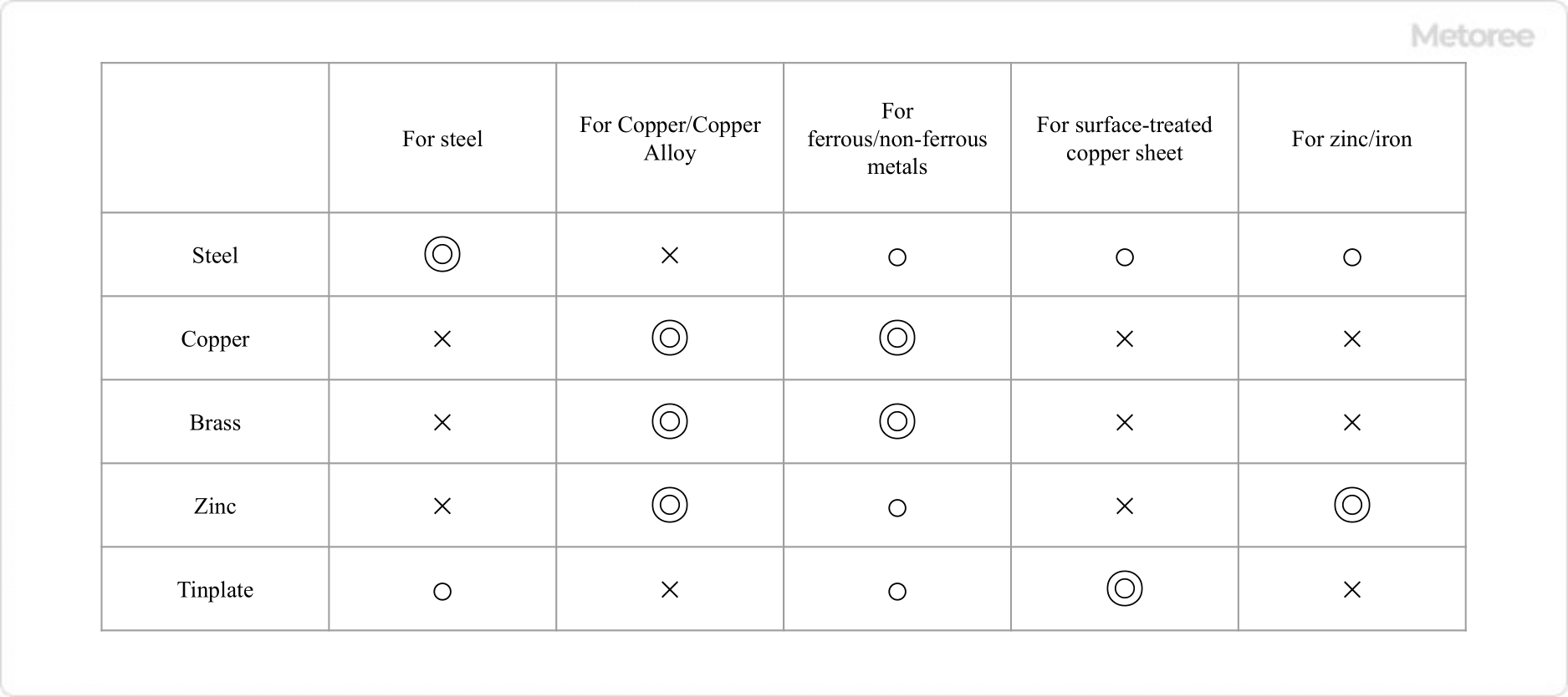

Figure 3. Types of Anti-Corrosion Paper and Whether Metals Can Be Used

Since there is no rust inhibitor that is effective on all metals, it is necessary to use rust-proof paper that contains the appropriate rust inhibitor for the target metal. To give an example, rust-proof paper specifically designed for steel is not effective on copper.

Rust-proof paper for ferrous/non-ferrous metals has been developed that can be used when steel and copper coexist, but it will be less effective than using one specifically for each metal.

2. Classification by Wrapping Paper Material

When rust-proof paper is used for wrapping, it must be strong enough to withstand wrapping operations and handling after wrapping. Basically, kraft paper (40-100 m2) of a thickness appropriate for the uses of the paper is used. However, when the paper is inserted into a sealed space, it does not require any particular strength, so using a paper with a thinner thickness is not a problem.

In addition, when packaging slit coils, etc., rust-proof paper based on crepe paper (wrinkled paper) provides an excellent fit.