What Is an Iron Wire?

Iron wire is made by drawing low-carbon mild steel into a long, linear shape. It is distinct from steel wire, though both are derived from steel.

Iron wire is made by drawing low-carbon mild steel into a long, linear shape. It is distinct from steel wire, though both are derived from steel.

The production of iron wire involves cold working and may include additional processes like zinc plating, resin coating, heat treatment, and deformation with rollers. The materials used are primarily mild steel wire rods. Iron wire comes in various standardized forms, including plain iron wire, synthetic resin-coated wire, and color-coated, galvanized wire. Hot-dip aluminized and galvanized iron wires are also common.

Uses of Iron Wires

Iron wires have diverse applications. Ordinary iron wires are used for plating and welding. Specific types, like nail iron wires, are available for specialized uses. Annealed iron wires, known for their flexibility, are used in wire mesh, binding, and concrete reinforcement.

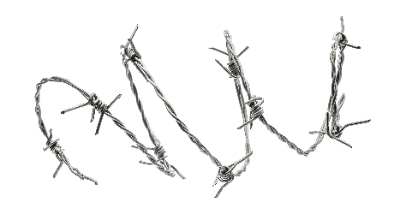

Binding wires, often galvanized and resin-coated, are standardized in thicknesses such as 0.9, 1.2, or 1.6 mm. They are used for supporting and fixing electrical wires and cables, and for priming wires in conduit pipes. Barbed iron wires, with pointed metal thorns, are used for security and crop protection.

Characteristics of Iron Wires

Iron wires are prone to rust and are usually protected by plating, surface treatment, painting, or resin coating. Galvanization is a popular method, forming an iron-zinc alloy layer that protects against environmental elements and corrosion. The service life of galvanized iron wires is determined by the thickness of this layer.

Annealed iron wires are heat-treated and gradually cooled, reducing their strength but increasing flexibility. This makes them suitable for bundling and wire mesh. Streamlined and automated manufacturing processes for annealed iron wires involve pickling, coating, cold-drawing, and annealing, contributing to cost reduction.