What Is a Fine U-Nut?

Fine U-Nuts are a type of locknut with a function or mechanism to prevent the loosening of a screw and are mainly used for bearings.

Locknuts are generally used in combination with lock washers to prevent loosening. In addition, there are hard locknuts that have an anti-looseness mechanism.

Fine U-nuts are used in many machines and equipment that use bearings because of their simple structure and easy tightening as lock nuts with an anti-looseness mechanism.

Uses of Fine U-Nuts

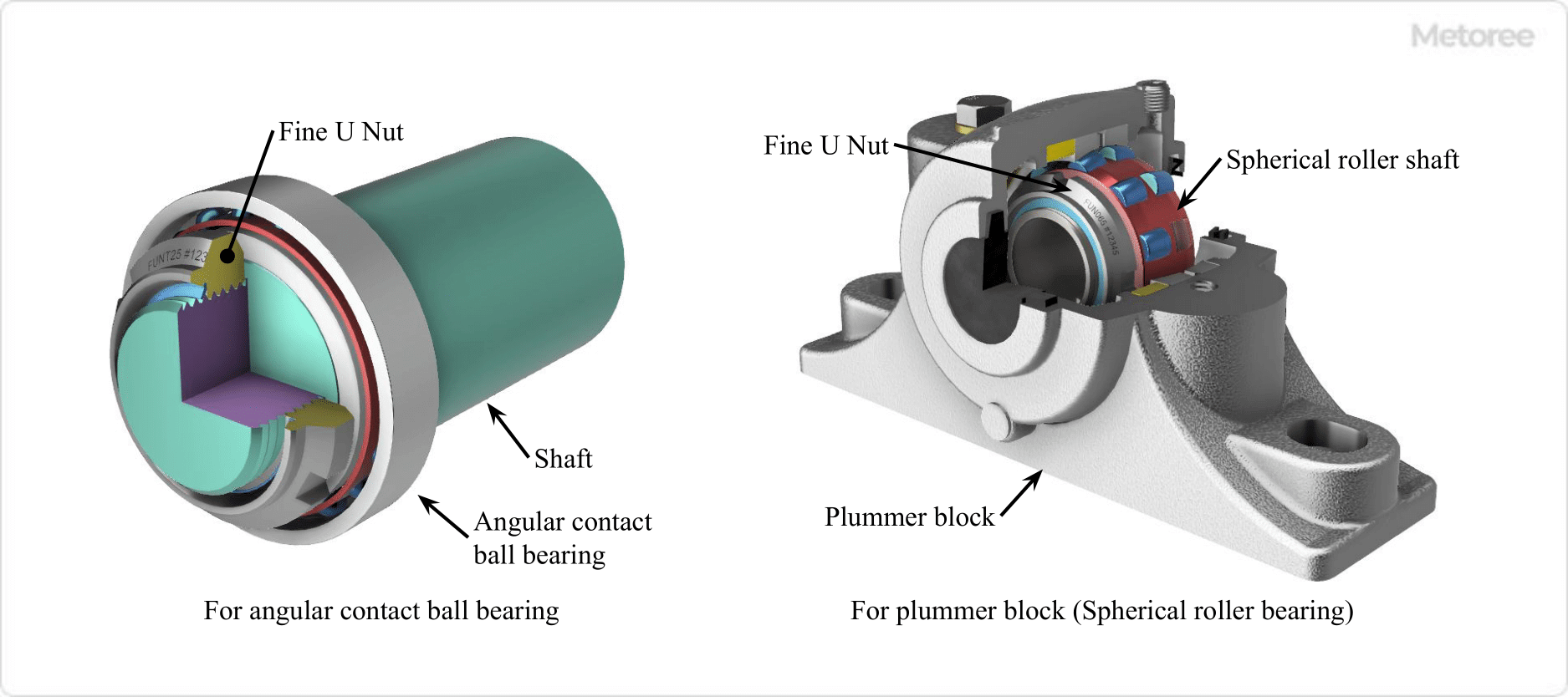

Figure 1. Example of Fine U-Nut use

Fine U-nuts can be applied when bearing locknuts are used, replacing the conventional method of securing bearings with a combination of locknut and lock washer.

Locknuts for bearings are mainly used when angular contact ball bearings, tapered roller bearings, spherical ball bearings, and adapter sleeves for tapered bores of spherical roller bearings are used, and the shaft (rotating shaft) thread is machined and the locknut is used to align, secure, and preload the bearing inner ring. The locknut is used to align, secure, and adjust the preload of the bearing inner ring.

Principle of Fine U-Nuts

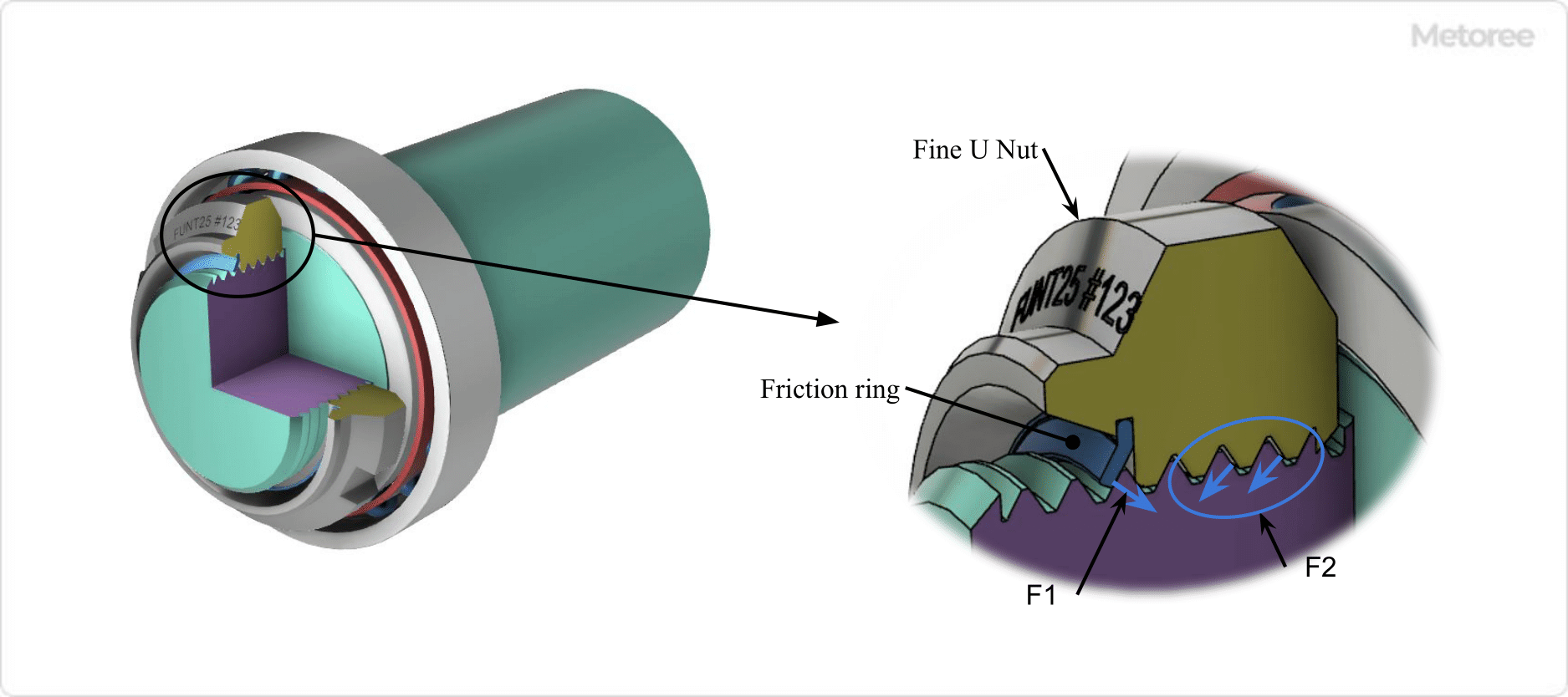

Figure 2. Principle of Fine U-Nut

The Fine U-nut’s anti-looseness mechanism is a type of friction ring lock nut or preveling torque type nut. A ring called a friction ring is fitted on the side opposite the bearing of the lock nut for the bearing, and the outer circumference of the nut is fixed and integrated through a process of crimping. Crimping is a method of joining and fastening two parts by mechanically applying pressure to plastically deform the metal.

When a fine U-nut is screwed onto a shaft, a friction ring is inserted into the valley of the shaft thread. As it is further tightened, the friction ring deforms along the thread to generate a pushing force F1 against the thread and a frictional force F2 between the male and female threads.

F1 and F2 work in opposite directions to prevent the reduction of frictional force between the male and female screws, which is the cause of screw loosening.

Features of Fine U-Nuts

Features of the FINE U-nut are as follows

- Fastening at any position is possible

- No advanced skills are required for the installation

- Reusable

- No grooving of the shaft required

- Improved rotational balance between shaft and bearing

- Reduced number of parts

In particular, the friction ring type anti-looseness mechanism provides an anti-looseness effect regardless of the mounting position (tightening position) of the nut, and the tightening torque can be easily controlled, eliminating the need for advanced skills in installation and removal operations.

If there is no abnormal deformation of the friction ring or the nut itself, the nut can be reused after 10 times of mounting and dismounting with only a slight decrease in axial force. In addition, the material used is metal and can be used in high-temperature atmospheres up to about 300°C.

When a standard lock nut is used, a groove must be machined on the shaft where the projection on the inside of the lock washer fits to prevent the lock washer from turning.

Other Information on Fine U-Nuts

1. Standard Locknut

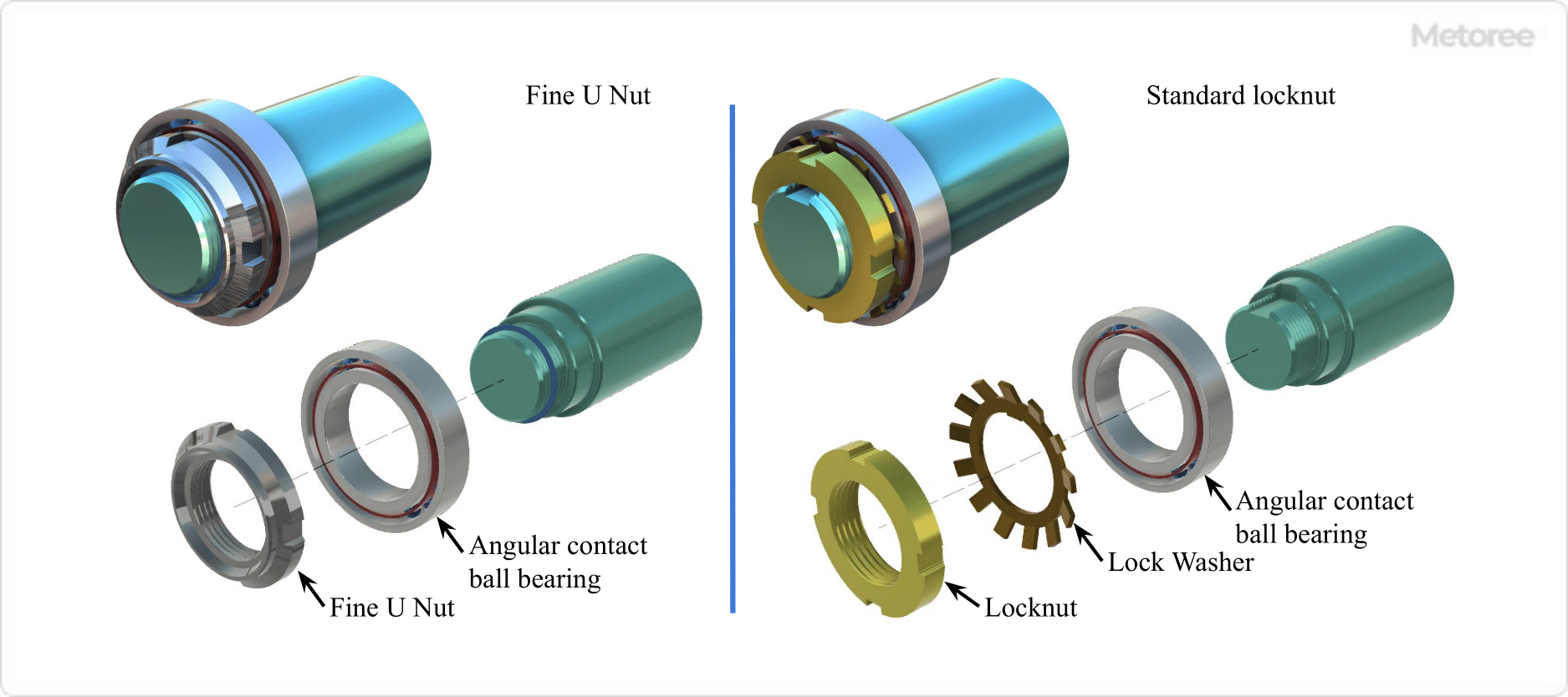

Figure 3. Comparison of Fine U Nut and Standard Lock Nut

The general method of preventing loosening is to use a standard locknut and lock washer (washer) as specified in JIS B1554 Rolling bearings – Locknuts, washers, and retaining clip. In this case, the inner projection (jaw) of the lock washer fits into the shaft groove and the outer projection fits into the groove of the lock nut to prevent loosening.

2. Number of Friction Rings

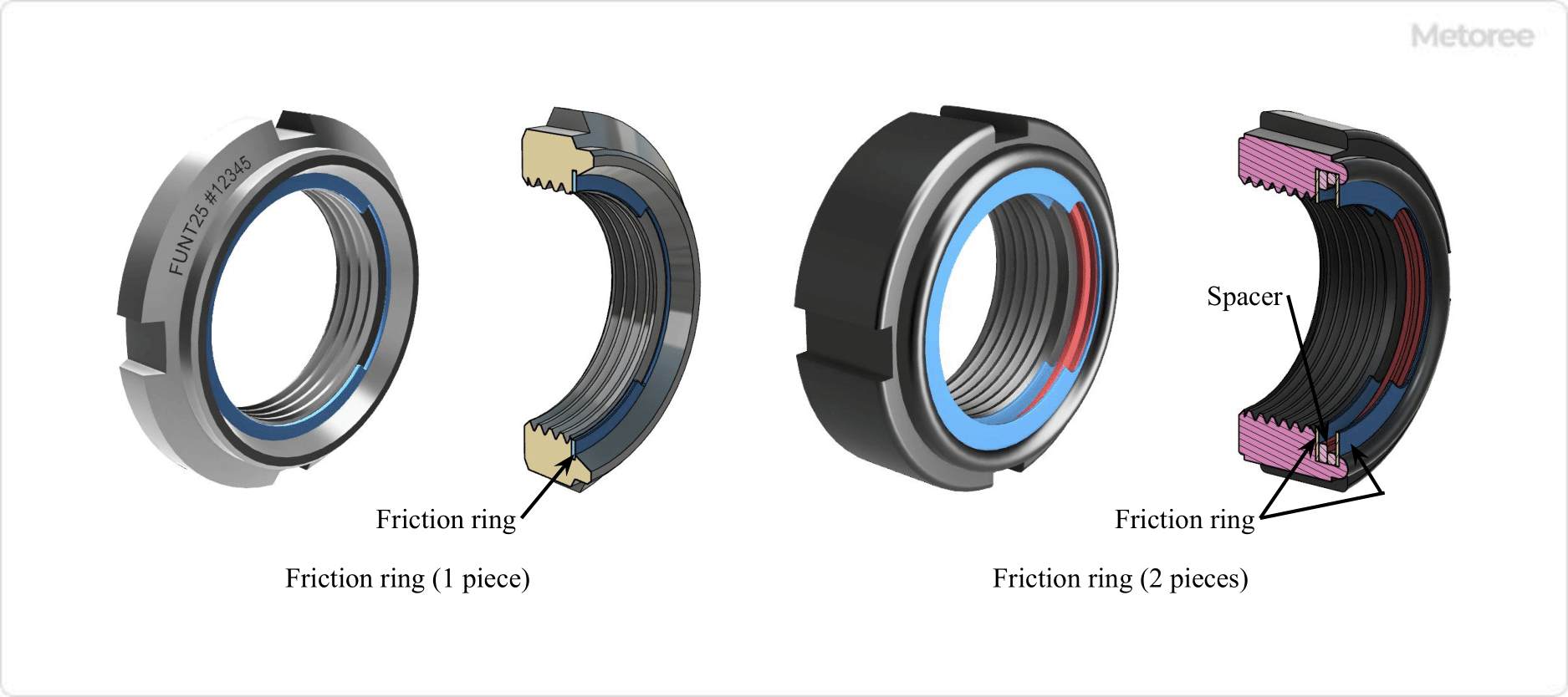

Figure 4. Number of Friction Rings

General fine U-nuts have a single friction ring, but special specifications are available with two friction rings for improved loosening prevention.