What Is a Metal 3D Printer?

A metal 3D printer is a metal processing method that uses molten metal to form parts like a printer based on 3D data created on a PC or other device.

A metal 3D printer is a metal processing method that uses molten metal to form parts like a printer based on 3D data created on a PC or other device.

The technology of metal 3D printers is not yet as widespread as that of cutting processes. However, it can produce more complex shapes than precision machining using a 5-axis machining center, and it can also produce shapes that cutting tools cannot reach.

The number of companies introducing 3D printers has been increasing in recent years due to their cost-effectiveness.

Uses of Metal 3D Printers

Metal 3D printers are used in the automotive, aerospace, and medical industries, where high performance is required.

For example, 3D printers are being used to produce parts with complex shapes such as fuel injection nozzles used in aircraft jet engines, turbine blades, and rocket engine parts, as well as parts for weight reduction and electrification in the automotive industry.

In the medical field, 3D printers are used to create implants for artificial joints.

Characteristics of Metal 3D Printers

There are three main types of metal 3D printers, each with different features.

Powder Head Method

This method lays down small spherical powders of 10 to 60 µm in size, irradiates the powder with an electron beam or laser, and melts and solidifies only the necessary portions to form the shape.

This is the most mainstream method used in metal 3D printers today and is characterized by its high dimensional accuracy. However, its drawback is that it takes a long time to produce.

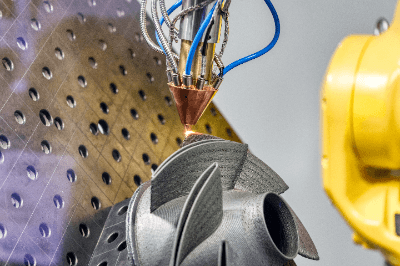

Directional Energy Deposition Method

This method uses a laser as the heat source for melting metal. Molding is performed by irradiating a jet of metal powder from a nozzle with a laser at the center, melting the metal as it is injected.

This method is characterized by its flexibility, which can accommodate large parts by changing the length of the three axes (XYZ). It can also be used to repair partial wall fillings (laser cladding) on worn molds.

FDM Method

This method involves extruding a mixture of thermoplastic resin, which softens with heat, and metal powder, and layering the mixture to form the part.

This method is relatively inexpensive but requires degreasing and finishing work separately due to shrinkage during sintering.