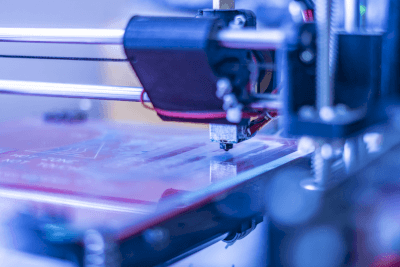

What Is a Nano 3D Printer?

A Nano 3D printer is a precision 3D printer that boasts a resolution of 100 nanometers (0.1μm) among all types of 3D printers.

A Nano 3D printer is a precision 3D printer that boasts a resolution of 100 nanometers (0.1μm) among all types of 3D printers.

It is capable of modeling at the nanoscale, making it possible to produce microscopic-scale models that could not be produced with conventional 3D printers.

In addition, due to the thin and smooth layers, it becomes possible to obtain extremely smooth surfaces in terms of surface roughness. This characteristic allows for the creation of high-precision products, even in the case of small parts.

Uses of Nano 3D Printers

Nano 3D printer technology is used in a wide variety of fields.

For example, nano 3D printers are being used in the medical field, where precision is required, as well as in the art and entertainment industry for miniature art such as figurines, and are gaining momentum as a new form of art.

In addition, the improved precision of the bonding surface of a collection of small parts, such as the base of an electronic circuit, is expected to reduce defects in electronic devices, such as faulty connections.

Features of Nano 3D Printers

The FDM (Fused Deposition Modeling) method used in inexpensive 3D printers has rough seams between the layers, making it difficult to achieve high precision in modeling. The “stereolithography” method is used.

The advantages of the stereolithography method lie in its high fabrication speed and the fact that the material does not reach high temperatures as in the FDM method, making it difficult to shrink.

In addition, since the stacking marks are not noticeable, a smooth surface can be obtained, making it easy to paint, and making it suitable for figure and model making.

Furthermore, since acrylic resins can be used to create highly transparent moldings, they are used to create prototypes such as car lights.

One disadvantage is that it is vulnerable to direct sunlight due to its property of curing in response to ultraviolet light, and must be stored in a cool, dark place, which makes storage more costly.

Another disadvantage is the time-consuming post-processing, such as polishing and coating.