What Is Super Cleaner?

Super cleaner, a potent cleaning agent, effectively removes stains from diverse materials. Its versatility allows its use on materials ranging from metals to plastics. This cleaner effectively tackles various stains, including oil and watermarks.

Super cleaner, a potent cleaning agent, effectively removes stains from diverse materials. Its versatility allows its use on materials ranging from metals to plastics. This cleaner effectively tackles various stains, including oil and watermarks.

Available in various forms like liquid, cream, or mousse, it caters to different cleaning needs. Both commercial and domestic versions are available, with the latter easily found in home centers.

Uses of Super Cleaners

Super cleaners are particularly useful in areas like kitchens, where grease stains are common due to cooking. They effectively remove stubborn, burnt-on oil stains that ordinary cleaners struggle with. In bathrooms, they tackle water and soap stains that form tenacious marks when combined with metal components in the water. Super cleaners can lift and remove even these challenging stains.

Principle of Super Cleaners

Super cleaners vary in liquid properties and mechanisms for stain removal, depending on their formulation:

- Acidic Super Cleaner: Contains acids like citric acid. They work through a neutralization reaction with basic stains, producing water-soluble salts that lift the stains.

- Neutral Super Cleaner: Contains surfactants that have both hydrophilic and hydrophobic groups. They encapsulate dirt in micelles, making it easier to wash away, and particularly effective for oil stains.

Both acidic and neutral types are sometimes diluted with water to adjust their concentration.

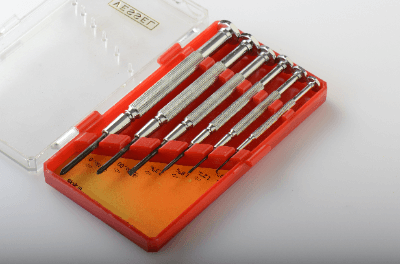

Precision screwdrivers are specialized tools used for tightening small screws. These

Precision screwdrivers are specialized tools used for tightening small screws. These

Adapter cables are designed to transfer signals from input/output terminals for video, audio, data, etc., and connect them to other devices.

Adapter cables are designed to transfer signals from input/output terminals for video, audio, data, etc., and connect them to other devices.