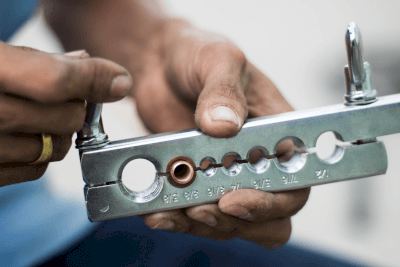

What Is a Flaring Tool?

A flaring tool is used to flare wires by deforming their tips into a trumpet shape. This method allows for the installation of a flare joint to connect two wires. Mainly used for processing soft wiring in air conditioning systems, flaring tools are popular for their ease of use.

Uses of Flaring Tools

Flaring tools are essential for connecting various types of wiring, such as in air conditioners. Copper pipes from the indoor and outdoor units are connected using flaring tools. By flaring one end, the other can be wrapped around it for connection. The wires are then securely joined with a nut, creating a strong, seamless bond that prevents refrigerant gas leakage and maintains cooling efficiency.

Principle of Flaring Tools

Flaring tools consist of a handle and holes of various sizes to hold the wiring. The wire is clamped between these holes, and when the handle is turned, the wire’s tip expands into a trumpet shape. There are two types of flaring tools:

- Manual Type

In this type, the user manually rotates the handle to gradually widen the wire’s tip. When the handle feels light, the flaring is complete. - Ratchet Type

This type includes a ratchet handle. The wire’s tip is spread by a reciprocating motion, eliminating the need for rotation. It is simpler to use than the manual type.

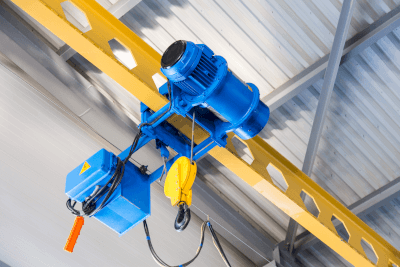

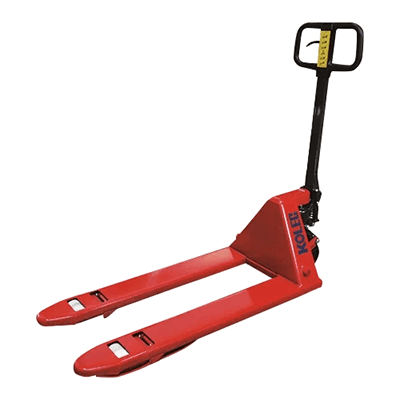

A trolley is a

A trolley is a

Carbide bars, or cemented

Carbide bars, or cemented

A plastic expansion joint is a component used for connecting pipes in various construction projects. Commonly used in DIY projects, these joints facilitate the connection of pipes at right angles or for extending lengths. Available in removable and fixed (adhesive-injected) types, plastic expansion joints are lightweight, waterproof, and suitable for outdoor use.

A plastic expansion joint is a component used for connecting pipes in various construction projects. Commonly used in DIY projects, these joints facilitate the connection of pipes at right angles or for extending lengths. Available in removable and fixed (adhesive-injected) types, plastic expansion joints are lightweight, waterproof, and suitable for outdoor use.