What Is an Actuator?

An actuator is a drive device that converts various types of input energy into physical motion.

In addition to electricity, the energy input to an actuator can be pneumatic, hydraulic, electromagnetic, steam, heat, etc. By using the energy converted by an actuator, it is possible to control the movement associated with the movement of objects.

Applications of Actuators

Actuators are used in a wide variety of applications, either as devices for simple motions such as extending, bending, and turning or to generate power continuously, such as motors and engines.

Depending on the energy input, actuators are generally classified into three main categories

- Electric Actuators: Industrial robots and transport equipment that require high-precision positioning.

- Hydraulic Actuators: Machine tools and construction equipment that require high thrust

- Pneumatic Actuators: General industrial and food production equipment requiring clean and simple structures

Principles of Actuators

Actuators can be broadly classified into the following principles

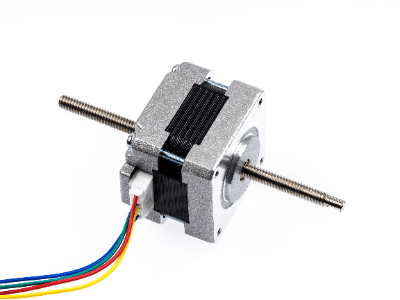

1. Electric Actuators

Electric actuators are driving devices consisting of ball screws, linear guides, servomotors, etc., and are used to transport production equipment.

Electric actuators include servomotors that use electricity as energy, electromagnetic actuators that use magnetic force from electromagnets as energy, and piezoelectric actuators that use piezoelectric elements that deform when voltage is applied.

2. Hydraulic Actuator

Hydraulic actuators use Pascal’s principle to generate fluid power, so they can provide large power even though they are small.

3. Pneumatic Actuator

Pneumatic actuators use pneumatic pressure as the power source, whereas hydraulic actuators require high loads, high pressure, and heavy equipment, so they are used as a safe method with low loads and little risk of fire.

Other Information on Actuators

1. Distinction Between Hydraulic and Electric Actuators

Actuator propulsion energy is mainly used at a power density of about 1k (W/kg), with hydraulic energy control used for higher power applications and electric energy control used for lower power applications.

Electric actuators have also been actively improving their power with technological innovations in recent years, but the power has improved significantly only in the field of brushless DC motors for small to medium actuator applications, while AC servomotors for large applications have not seen a significant increase in power since the early 2000s. AC servomotors for large-size applications have not seen a significant increase in power since the early 2000s.

Therefore, especially in the field of machine tools and construction machinery in factories that require large power densities of 10k(W/kg), hydraulic actuators are the sole domain of these applications, and electric-controlled actuators are not used in this field. However, it is also true that hydraulic energy control is desired to be electrically controlled if possible in this field from the viewpoints of running costs such as oil changes and maintenance, as well as environmental considerations.

2. Hybrid Actuator With Hydraulic and Electric Control

One of the recent technological trends is the development of hybrid actuators that combine hydraulic and electric control. Hydraulic control has generally been based on Pascal’s principle, but the problems with this type of actuator are that it requires piping equipment for oil circulation to control the flow rate of the servo valve of the working oil, which makes the equipment large, and that the working oil deteriorates due to the rise in exhaust heat temperature of the machine, which requires periodic oil changes and maintenance costs. This also caused high maintenance costs due to the deterioration of the working oil caused by the rise in the machine’s exhaust heat temperature.

The latest hybrid actuator with hydraulic and electric control enables final control of actuator output based on the drive speed of the electric servomotor rather than servo valve flow control, eliminating the need for extensive piping, and enabling highly efficient output control to suppress the rise in working oil temperature. This also reduces maintenance costs for oil changes and is suitable for environmental considerations.

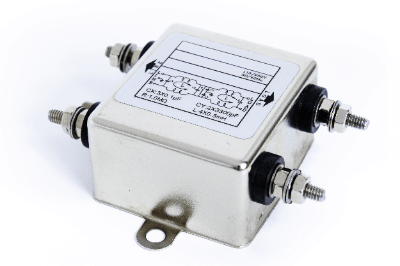

A noise filter is an electronic component used to remove noise from a power supply or signal.

A noise filter is an electronic component used to remove noise from a power supply or signal.

A heater is a general term for any device that generates heat.

A heater is a general term for any device that generates heat.

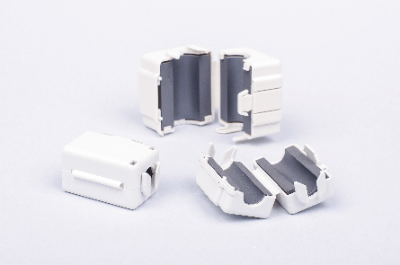

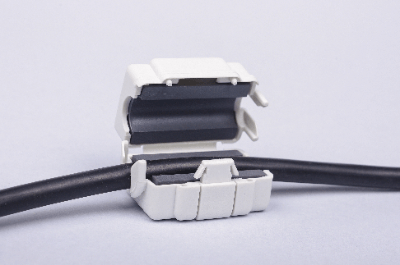

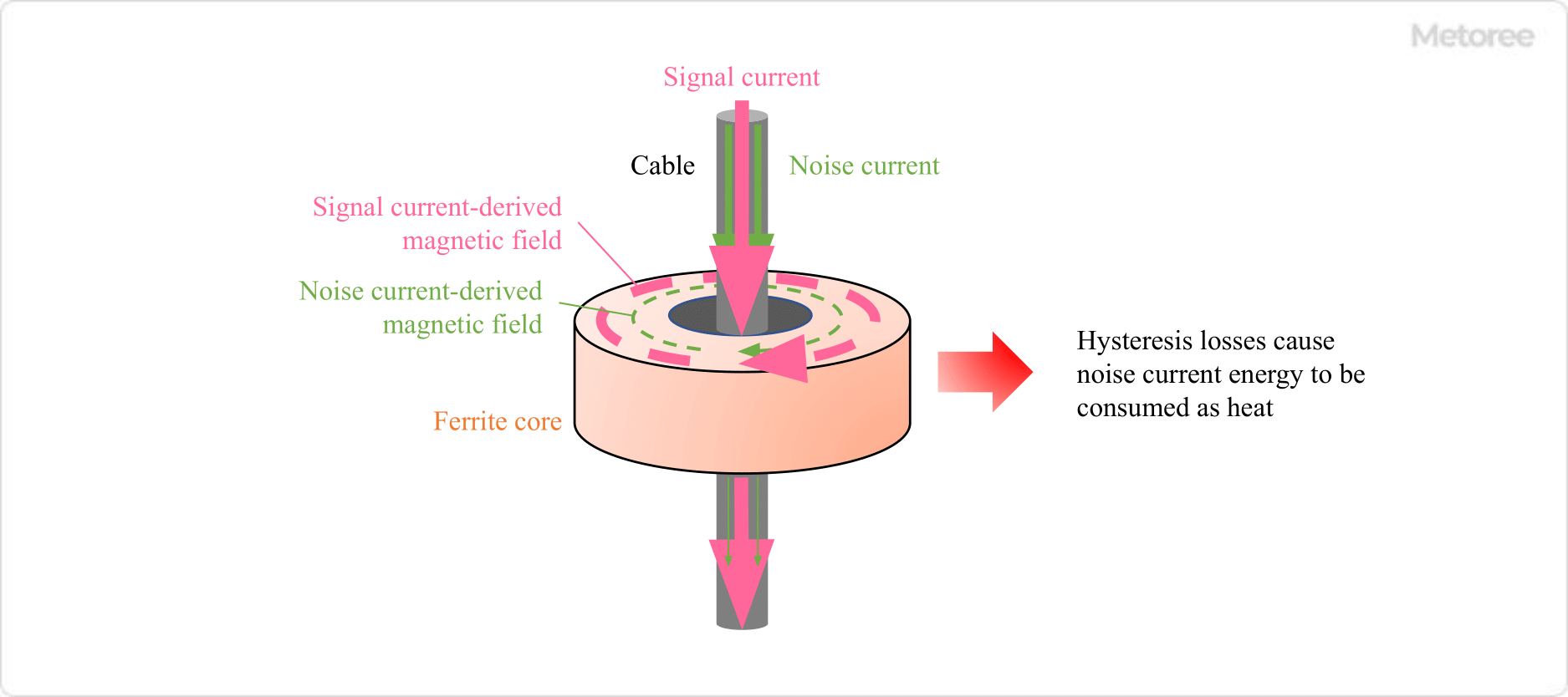

A ferrite core is a ceramic

A ferrite core is a ceramic

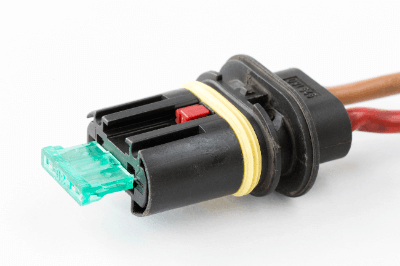

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.