What Are Infrared Sensors?

Infrared sensors are sensors that detect light rays in the infrared region.

Infrared sensors are sensors that detect light rays in the infrared region.

Light differs in color and characteristics depending on its wavelength. The wavelength of visible light is considered being around 400 nm to 800 nm, and light other than that is not visible to the eye. To the human eye, light rays in the 400 nm range appear purple, while light rays in the 800 nm range appear red. When referring to invisible light, light with a wavelength of 400 nm or less is called ultraviolet light, and light with a wavelength of 800 nm or more is called infrared light.

Infrared sensors are sensors that detect the above mentioned infrared rays. However, in addition to detecting infrared rays, there are also methods that emit infrared rays and detect reflected waves.

Uses of Infrared Sensors

Infrared sensors are used in a variety of ways in consumer products. A typical use is in TV remote controls. The TV’s infrared sensor receives the remote control’s operation signal. This takes advantage of the invisible nature of infrared light.

Infrared sensors are also used in thermometers. The temperature is detected using the characteristic that the hotter the substance is, the more infrared light it emits. Since temperatures can be detected quickly and without contact, they are useful during infectious disease outbreaks.

Infrared sensors are used in a wide range of industrial applications, including space development and military applications.

Types of Infrared Sensors

Infrared sensors have been actively researched and are available in a variety of materials. The principles are mainly divided into thermal and quantum types.

Infrared sensor wavelengths are classified into near infrared, mid infrared, and far infrared, and each sensor has its own area of expertise.

1. Thermal Infrared Sensors

A typical example of a thermal infrared sensor is a pyroelectric sensor. Pyroelectric infrared sensors are made of ferroelectric pyroelectric ceramics and utilize the pyroelectric effect. When the infrared sensor is heated, the amount of electric charge on the ceramic changes due to the pyroelectric effect. The sensor detects the electric current that flows according to the changed amount of charge. Even the slightest infrared radiation emitted from the human body can be detected.

Thermopile sensors are also a type of thermal type. A thermopile is a thermo-electromotive sensor that consists of multiple thermocouples and converts the thermal energy of infrared sensor into an electromotive force.

2. Quantum Infrared Sensor

Quantum infrared sensors are sensors that detect band gap energy as an electric current. The mechanism is the same as that of solar panels, which are made of elements that generate electricity from infrared rays. While the detection sensitivity is 100 to 1,000 times higher than that of thermal sensors, the heat generated by the sensor itself is also detected, so it must be cooled sufficiently.

Other Information on Infrared Sensors

1. Disadvantages of Infrared Sensors

Infrared sensors can malfunction or fail to operate. Cases of malfunction include when the sensor is blocked by an object that does not transmit far infrared sensors, such as glass or acrylic, or when the object to be detected is hardly moving.

Let us use an automatic door as an example. Automatic doors detect objects by the rate of change of infrared reflection. Due to its principle, if a persons wears clothes of the same color as the carpet or approaches an automatic door slowly, it might malfunction.

Heat sources other than the human body can also cause malfunctions. For example, infrared devices may malfunction in response to sunlight or incandescent light. Malfunctions can also occur when there is a sudden change in temperature in the vicinity of air conditioning or heating equipment.

2. Infrared Sensors and Automobiles

Driving at night increases the probability of accidents due to poor visibility. Infrared sensors are gaining attention as the new eyes that can solve nighttime driving problems and increase safety.

Night Vision Systems

Infrared sensors are used to identify pedestrians and other objects and visualize them on a display. Passive-type sensors directly detect far-infrared radiation, eliminating the need for light illumination.

The active type uses near-infrared lights to illuminate the road ahead, and the reflected light is captured by an infrared camera.

Vehicle Perimeter Monitor

Infrared cameras are installed on all four sides of the vehicle to detect pedestrians in blind spots. If pedestrians are present, an alarm is triggered when the vehicle starts, and a system has been developed to deter the vehicle from starting.

Air Conditioning Systems

An air conditioning control system has been developed that measures the surface temperature using far-infrared radiation emitted from the occupants and switches the air outlets.

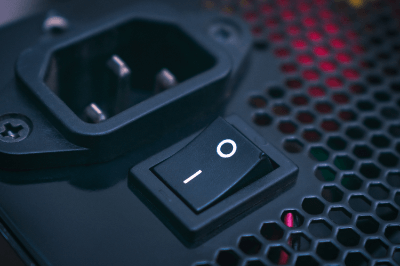

Rocker Switches are a type of manual switching device. Rocker switches are used to switch electrical circuits on and off by means of seesaw-like motion buttons.

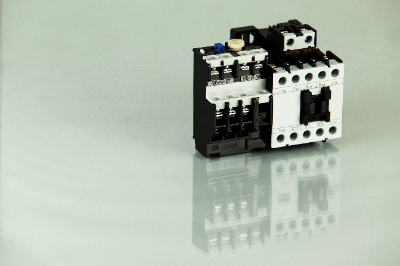

Rocker Switches are a type of manual switching device. Rocker switches are used to switch electrical circuits on and off by means of seesaw-like motion buttons. An electromagnetic switch is a switch that combines an

An electromagnetic switch is a switch that combines an  A Zener diode is a diode consisting of an n-type semiconductor and a p-type semiconductor connected together, and has a relatively small reverse voltage and a stable voltage value. They are also called constant voltage diodes.

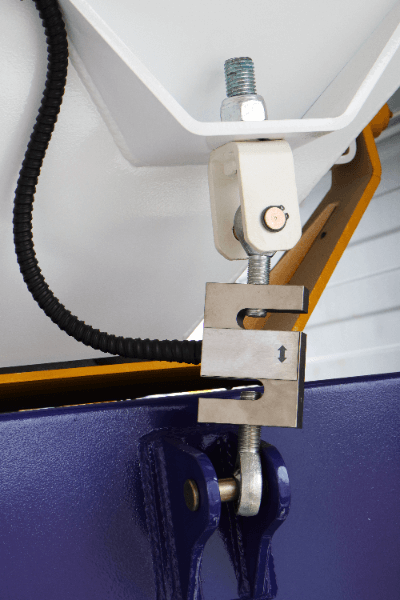

A Zener diode is a diode consisting of an n-type semiconductor and a p-type semiconductor connected together, and has a relatively small reverse voltage and a stable voltage value. They are also called constant voltage diodes. A load cell is a load

A load cell is a load

Lightning rods are structures that protect electrical equipment and the human body from lightning strikes.

Lightning rods are structures that protect electrical equipment and the human body from lightning strikes.