What Is a Silicon Carbide (SiC) MOSFET?

SiC MOSFET is a MOSFET that uses a silicon carbide (SiC) MOSFET, a compound semiconductor, instead of the conventional Si substrate.

MOSFETs are used for on/off switching, amplifiers, and other applications. By using SiC, a compound semiconductor, as the semiconductor substrate material, it is possible to reduce the resistance when voltage is applied compared to a conventional silicon carbide (SiC) MOSFET.

As a result, switching loss during turn-off,and power loss during power operation can be reduced. This can improve the performance of the semiconductor chip and reduce the cooling capacity required during transistor operation, leading to downsizing of the product itself.

Uses of Silicon Carbide (SiC) MOSFETs

SiC MOSFETs are used in many semiconductor products, such as relays, switching power supplies, and image sensors in the field of power electronics. SiC MOSFETs are also used in communication equipment in many cases.

When selecting a silicon carbide (SiC) MOSFET, the operating conditions of the product application must be considered, i.e., absolute maximum ratings, electrical characteristics, package use and size, etc.

Principle of the Silicon Carbide (SiC) MOSFETs

Silicon carbide (SiC) MOSFETs can achieve a MOSFET structure that allows low ON resistance and low-loss operation during turnoff, while maintaining a similar level of withstand voltage. This is because the active layer thickness can be reduced because the transistor is made of SiC substrate, which has properties of band gap energy about 3 times higher and breakdown field strength about 10 times higher than that of Si substrate.

A silicon carbide (SiC) MOSFET has a stacked structure of p-type and n-type semiconductors. Usually, the n-type semiconductor is stacked on top of the p-type semiconductor. The drain and source electrodes are attached to the n-type semiconductor, and the oxide insulating layer and gate electrodes are attached between the n-type semiconductors. In addition, SiC (silicon carbide), a compound semiconductor, is used as an epi-substrate for the silicon wafer of the body.

In a MOSFET, applying a positive voltage to the gate causes a current to flow between the source and drain. In this case, a silicon carbide (SiC) MOSFET, which uses SiC in the silicon wafer, can operate with a larger voltage and current between the source and drain than a MOSFET that uses only Si. Since the concentration of impurities in the semiconductor can be increased, losses can be reduced and the size of the MOSFET can be made smaller.

Other Information on Silicon Carbide(SiC) MOSFETs

1. Distinction Between Silicon Carbide (SiC) MOSFETs and IGBTs

IGBTs are transistors used for applications in the high-power range, which are difficult to handle with ordinary Si MOSFETs, but recently SiC MOSFET devices are being used in this range. SiC MOSFET devices are being used in this area because SiC has a large band gap energy, which allows it to operate at higher temperatures than IGBTs. Another reason is that SiC MOSFETs can overcome the problem of large switching losses in the subsequent bipolar transistor in the case of IGBTs.

In the past, SiC epi-substrates had a small diameter, making mass production and cost difficult. Recently, however, it has become possible to use 8-inch substrates, and mass production and prices have been improving.

SiC is being actively used in relatively large power handling applications exceeding 10 kW, such as electric vehicle (EV) applications, power generation system applications, and residential power applications.

2. Differences Between SiC and GaN Devices

Along with SiC, gallium nitride (GaN) is another wide band gap semiconductor that is attracting attention. GaN has a larger band gap energy and higher dielectric breakdown strength than SiC, and is the subject of active research at research institutes.

Since GaN generally consists of a GaN active layer on a Si substrate, it is difficult to support high-power applications as well as SiC MOSFETs. In the market, applications that handle power equivalent to 1KW are relatively being considered. Examples include high power amplifier applications for 5G base stations and battery charging applications via PC or USB.

GaN devices, like silicon carbide (SiC) MOSFETs, can operate at high temperatures and do not require cooling equipment or excessive heat removal structures, which has led to their widespread use in recent years as compact PC power adapters.

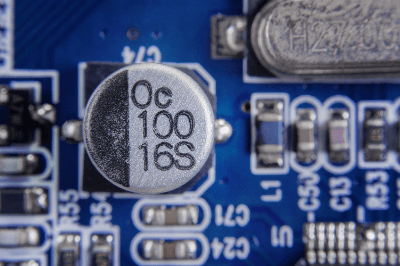

Aluminum electrolytic capacitors are small

Aluminum electrolytic capacitors are small