What Is a Track Dolly?

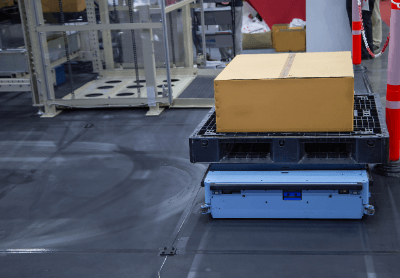

A track dolly is a type of dolly specifically designed to move along a track, commonly used in factories and warehouses for transporting materials and products. Due to their design, track dollies provide high stability by having a large contact area with the track. This stability is crucial for high-speed operation and maneuvering around curves. Typically, their wheels are made of steel or other metals to create optimal frictional forces with the track, reducing the force required for transport and thus enhancing efficiency.

However, proper track maintenance is essential to ensure the accurate and safe operation of track dollies. This includes maintaining the track’s inclination, and curve radius, and ensuring it is free of obstacles.

Uses of Track Dollies

Track dollies have diverse applications:

1. Logistics and Freight Transportation

They are widely used in warehouses and factories to transport large quantities of goods and cargo, moving efficiently on rails to save labor and increase work efficiency.

2. Moving Industrial Equipment

Track dollies facilitate the movement of heavy industrial equipment within a building for rearrangement or maintenance, enabling precise placement of the equipment.

3. Personnel Transportation

In large facilities like airport terminals and exhibition halls, track dollies are implemented for efficient personnel transportation.

Principle of Track Dollies

Track dollies are designed to move on tracks, generally comprising rails, a bogie, and a drive mechanism. The rails are fixed to the floor or ground, dictating the dolly’s operating path. The bogie frame supports the dolly on the rails, with wheels that adhere closely to the rails for stable movement. Many track dollies are equipped with a drive mechanism, often electric motors, for autonomous movement.

How to Select a Track Dolly

When selecting a track dolly, consider:

1. Type of Material to Be Transported

The type of material, such as lightweight boxes, long objects, or liquid containers, dictates the dolly’s design, including the shape of the load bed and fixing devices.

2. Loading Capacity

Choose a dolly with the appropriate loading capacity based on the weight of the cargo, and consider future demand increases.

3. Drive Source

Consider the power source for the motor, focusing on efficient and sustainable options.

4. Transport Speed

Select a speed appropriate for the material type, transport distance, and job requirements. Also, consider the dolly’s ability to brake or decelerate in certain areas for safety and efficiency.