What Is a Jig Part?

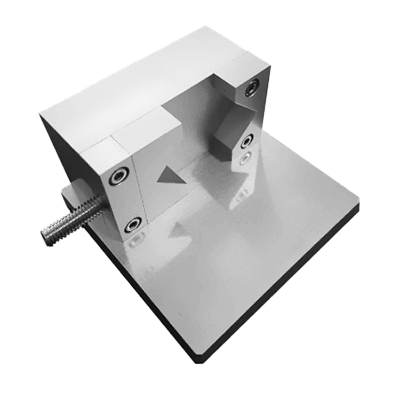

A jig is a positioning device used in machine tools to consistently produce products of high quality in large quantities.

Jigs are also employed to securely hold products in place. When a product is set and fixed within a jig, it remains in the same position, ensuring stability during processes like drilling. The jig is equipped with several components to position the product accurately.

These components include positioning pins, reference seat blocks, clampers, and rough guides.

Applications of Jig Parts

Below are examples of how jig parts are utilized:

- Machining Jigs

Jigs are employed on machine tools such as machining centers, lathes, and milling machines to eliminate the need for operators to make positioning adjustments for each product. - Assembly Jigs

In the assembly process, industrial robots are used to install components like bolts.

Unlike human workers, products must be consistently positioned; otherwise, assembly defects may occur when using industrial robots.

In the inspection process utilizing image processing, the product is assessed by comparing it to registered image data.

Features of Jig Parts

Key features of jig parts are explained for each type of jig component:

- Positioning Pin

These pins are inserted into the material hole, serving as the processing reference for the product.

Typically, a pair of pins is used, one with a round tip and the other with a diamond tip.

The round pin determines the product’s position, while the diamond pin determines the phase.

The reason for having one pin as diamond-shaped is to ensure proper product placement, as it would be challenging with two round pins. - Reference Seat Block

This component is attached to the jig to ensure the parallelism of the product.

It is designed to receive the position known as the reference seat of the product.

Normally, three points are used for receiving the product, as using four or more points could miss the reference seat.

To prevent incorrect product placement, some reference seats have air holes to monitor pressure inside the reference seat. - Clamper

The clamping mechanism holds the product firmly in place, preventing movement under load during processing.

Various power sources, such as springs, air, and hydraulic pressure, are used to secure the product. The selection is based on the clamping force required to withstand the processing load.