What Is a Sprue Bush?

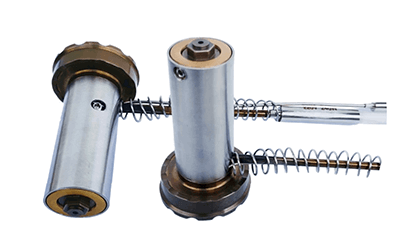

A sprue bush is a cylindrical component attached to a mold. “Sprue” is a word that means path (hot water channel) that carries molten resin (plastic) injected from the nozzle of a molding machine to the mold. A sprue bush is used to form this sprue.

This part consists of a sprue hole fitted with a taper and a base that is suitable for attaching injection molding machine nozzles closely to each other. It is one of the most important parts when molding resin in a mold.

Uses of Sprue Bushes

Sprue bushes are an indispensable part when melting resin and processing it in a mold. The size of processed products using this part varies from small to large, and the thickness also varies from thin to thick. These parts are used in a variety of situations, and the materials used include metal, highly durable diamond, and even specially processed resin. The appropriate sprue bush is used depending on the application.

Principle of Sprue Bushes

Molded resin products are made by sending plastic resin from an injection molding machine to a mold. The mold has a path for the resin to pass through, and the resin flows into the sprue, then the runner, and finally the gate, in that order. The cross section of the sprue is circular, and the sides are sloped. The runner is an important path through which the resin flows at once, so it must be just the right thickness for the molded product. If there are multiple molded products, the resin will branch off and flow through the runner, so it must be placed so that the resin flows evenly through it. The last gate is the entrance to the molded product, where the speed at which the plastic resin flows in is very important.

In the sprue bush, the molten resin passes through hundreds of thousands of times, and coagulation is repeated inside, so this part must have excellent abrasion resistance and good surface roughness. The radius of the entrance of the sprue bush should be about 1 to 2 mm larger than the radius of the nozzle tip, and the diameter of the sprue entrance should be about 0.5 to 1.0 mm larger than the nozzle diameter. If the size is inadequate, molten resin will leak out, making it difficult to pull out the sprue bush.