What Is a Cutting Duct?

A cutting duct is a component that allows electric wires to pass through its interior to improve the appearance and prevent electric shock.

A cutting duct is a component that allows electric wires to pass through its interior to improve the appearance and prevent electric shock.

A cutting duct is used when installing lighting fixtures and inside control panels. Since the wiring is not exposed, the scenery is improved and electric shock can be prevented.

Raceways are used as power feeders to install lighting fixtures, depending on the width of the installation location. For a width of 2 inches or less, a raceway is recommended, and for a width of 2 inches or more, a cutting duct is recommended.

Uses of Cutting Ducts

Cutting ducts are used inside control panels and to install lighting fixtures. It is used for commercial and industrial applications in addition to general household use. Specific applications are as follows:

- For home lighting

- Lighting for boutiques and exhibitions

- For internal wiring of control panels

- For lighting wiring in commercial facilities

- For wiring alignment in factories

In recent years, products that emphasize design have also been sold, expanding the use of these products as interior decoration. In many cases, they are also used for 2S purposes in factories, as they require fewer man-hours for installation.

Principle of Cutting Ducts

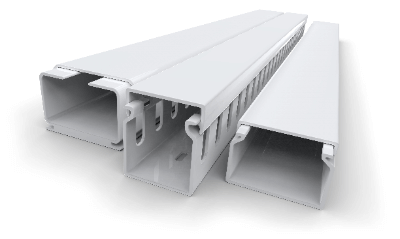

Cutting ducts are mainly made of PVC or other insulating resins. They are sold in lengths of 1 to 3 m and are divided into a cover and a main body.

The sides of the main body have evenly spaced holes for wiring, allowing cables to be inserted and removed. The resin portions between the side holes can be deformed by hand, allowing for easy adjustment according to the wire thickness, application, and position.

To make effective use of limited space, products with DIN rails mounted directly on the duct are also available, reducing the floor space of the distribution panel. This facilitates wiring work and increases flexibility in the design of equipment placement in the switchboard.

The corner type, which utilizes unused vertical corners in the distribution panel, allows the distribution panel itself to be downsized. The flexible shape makes it easier to install in the corners of the switchboard than the standard type.

Types of Cutting Ducts

Cutting ducts must be purchased in selected heights, widths, and lengths. For height, there is a lineup of ready-made products ranging from 30 to 120 mm. The most commonly used range is around 60 to 80 mm. The higher the height, the more wires can be introduced, but more installation space is required.

Widths can be selected from 20mm to 100mm, but 40mm to 60mm widths are most common. If thick wiring is to be introduced inside, 3 to 4 inches in width should be selected. Lengths are available from 3 to 10 ft. It is often purchased in 6 foot lengths.

Other Information on Cutting Ducts

1. Price of Cutting Ducts

Cutting ducts are relatively inexpensive components. Smaller size cutting ducts are less expensive, and larger size cutting ducts are more expensive. The typical price range is 10 to 200 dollars.

Prices also vary depending on the material. Cutting ducts are generally made of polyvinyl chloride resin, but cutting ducts made of special materials, such as polypropylene, are also available. Cutting ducts made of special materials are generally more expensive.

2. Color of Cutting Ducts

Since cutting ducts are generally made of polyvinyl chloride, most of them are gray if they are not painted. However, white, black, and milky white cutting ducts are also available to not disturb the landscape. Cutting ducts in special colors such as red and yellow are not often sold, so if you must have them, you will need to paint them yourself.