What Is a PCR Plate?

A PCR plate is a plastic experimental device used as a reaction vessel in PCR (Polymerase Chain Reaction) experiments. Unlike PCR tubes, PCR plates are suited for medium to large-scale experiments due to their capacity to handle a larger number of samples. Available in various sizes and colors, these plates are integral in automated processes.

Uses of PCR Plates

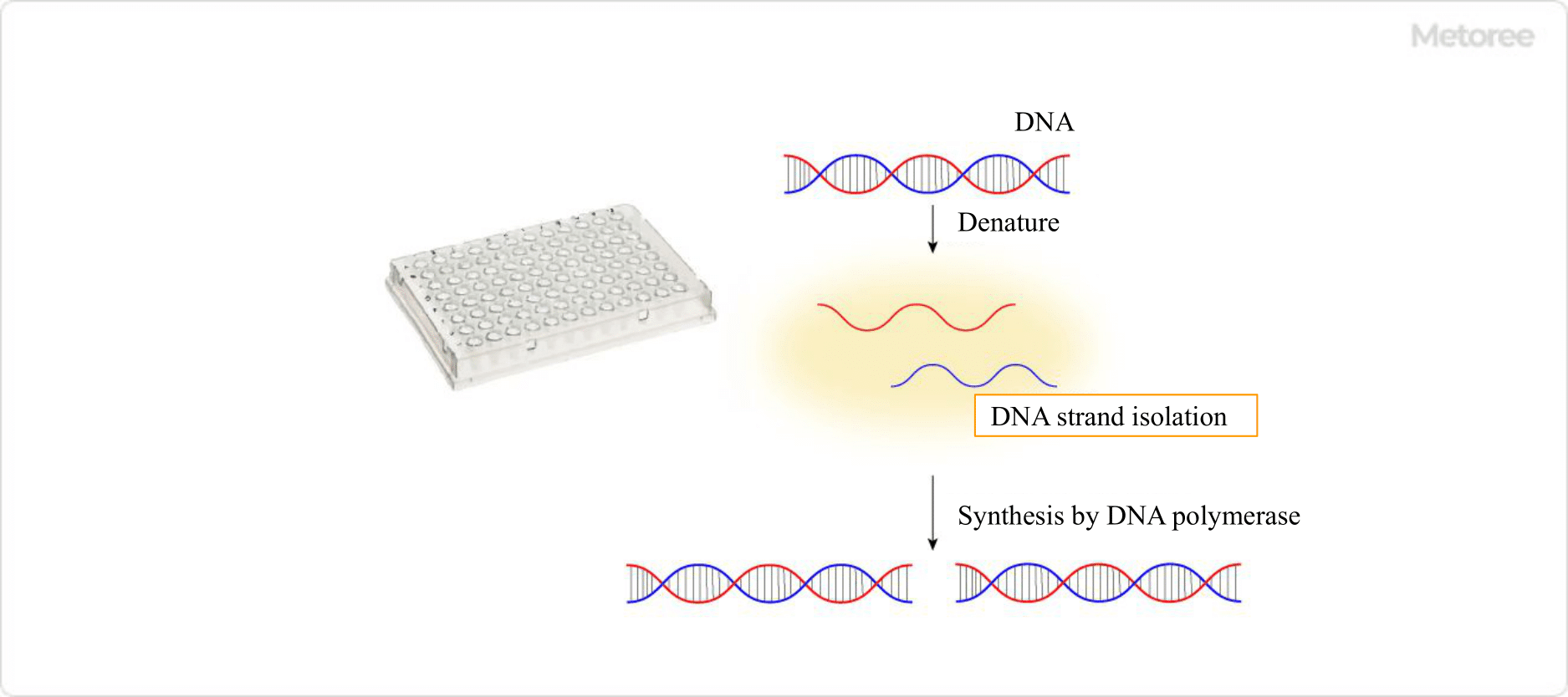

Figure 1. PCR plate and principle of PCR

PCR, a technique for amplifying specific DNA sequences, involves repeated cycles of denaturation, annealing, and elongation. A thermal cycler automates these temperature changes. Selecting the right PCR plates is crucial, depending on the thermal cycler’s specifications and the type of PCR being performed, such as standard, gradient, or real-time PCR/qPCR.

Structure of PCR Plates

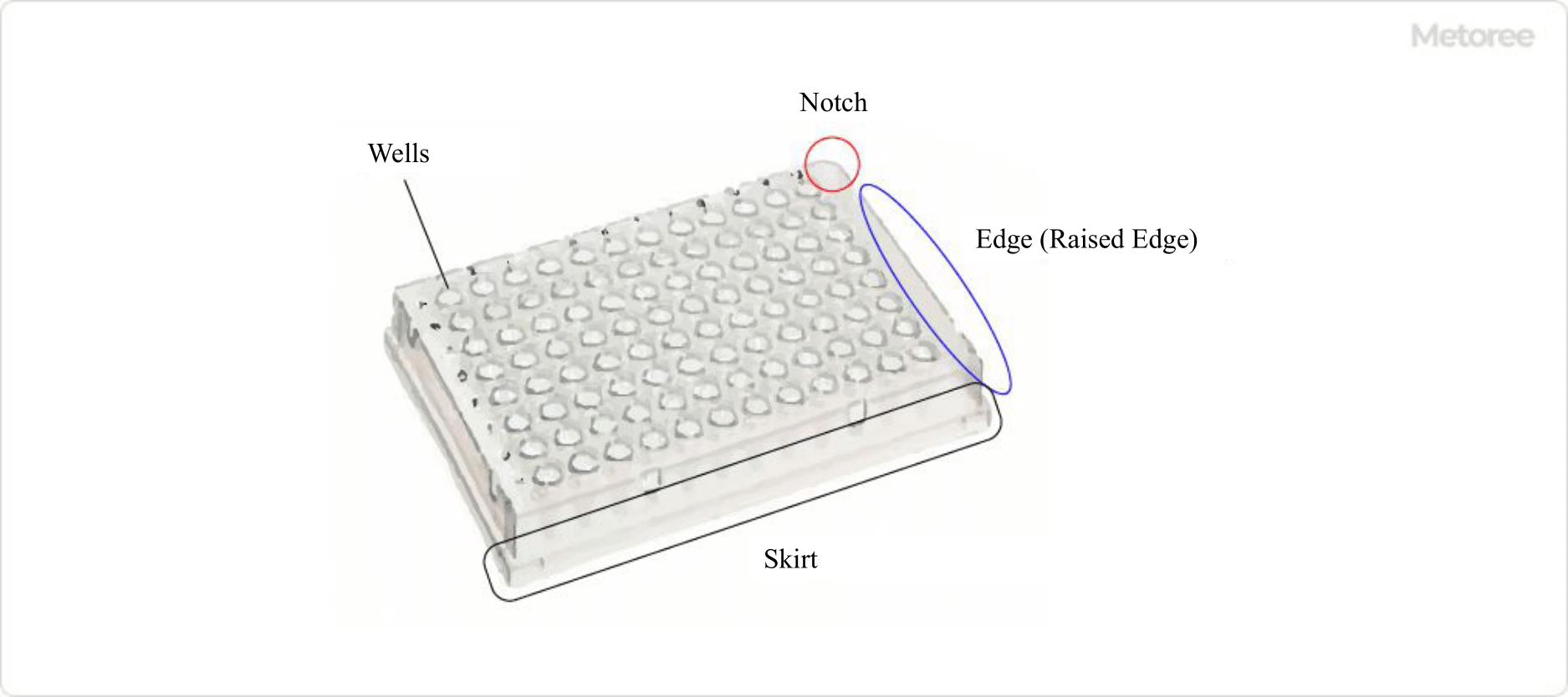

Figure 2. Names of the parts of a 96-well PCR plate

PCR plates, typically made from polypropylene, are designed for efficient heat transfer and minimal reaction component absorption. The choice of well color impacts the experiment’s visibility and sensitivity, especially in qPCR.

The production environment for PCR plates is highly controlled to prevent contamination that could interfere with PCR accuracy. The plates come in various sizes and colors, with different skirt styles and deck types to cater to diverse laboratory needs and equipment compatibility.

How to Choose PCR Plates

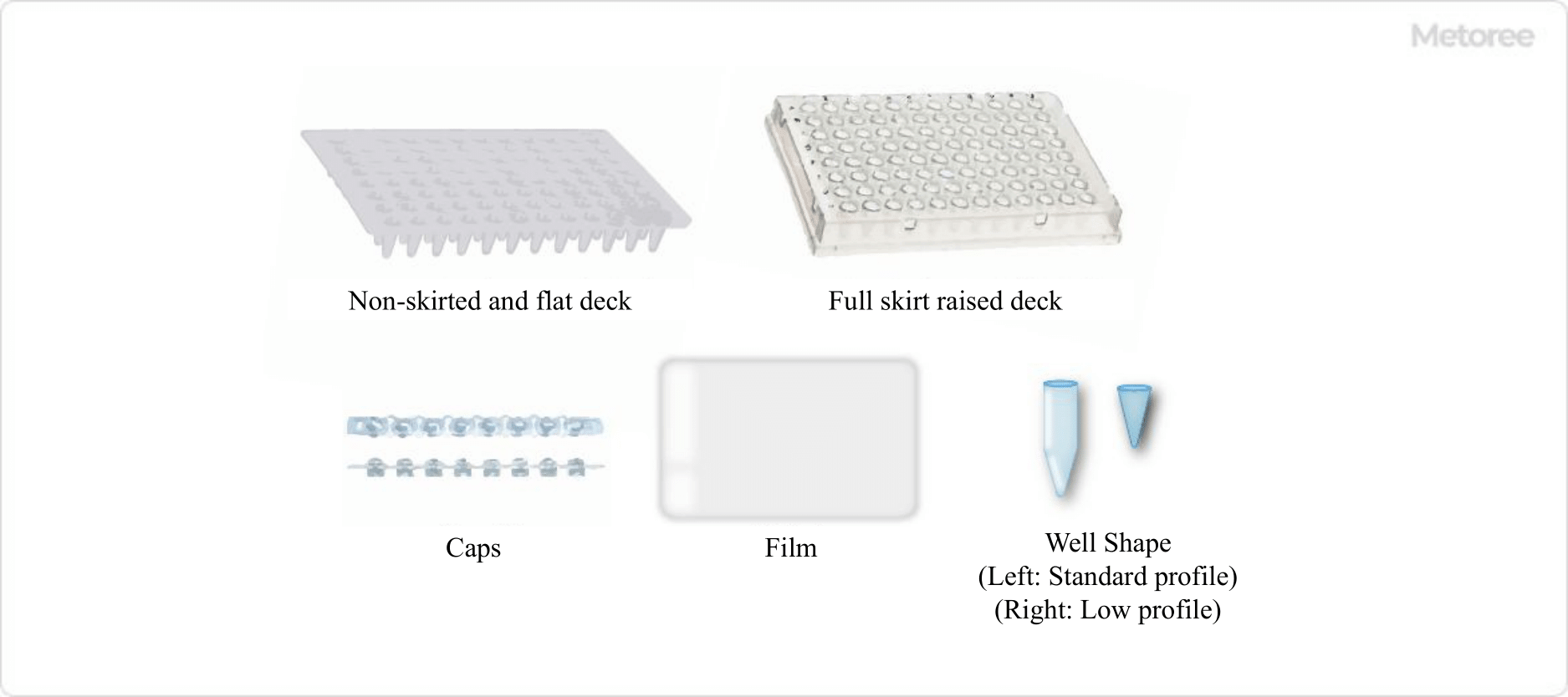

Figure 3. Examples of PCR plate / Component types

Choosing the right PCR plate involves considering the type of experiment, well color and volume, thermal cycler compatibility, and the need for automation. Transparent wells are ideal for visual checks, while white wells enhance qPCR sensitivity. The well size should match the reaction volume to avoid issues like inadequate heat transfer or sample evaporation.

Plate shape and skirt style should align with the thermal cycler’s specifications and any automation requirements, such as robotic handling or tracking. Plates with strong polycarbonate frames are preferable for automated processes due to their durability under mechanical stress and thermal cycling.