What Is a Cement Resistor?

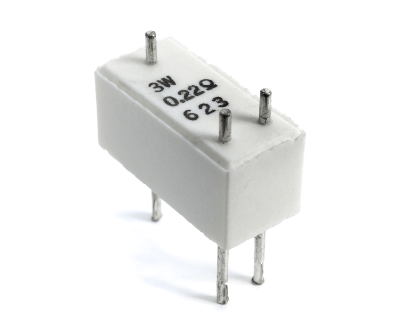

A cement resistor is an electronic circuit component that acts as a resistance to the current flowing in a circuit.

A cement resistor is an electronic circuit component that acts as a resistance to the current flowing in a circuit.

There are various types of resistors, of which cement resistor is classified as wire-wound resistors. This is because many of them use wire-wound resistive elements to block the flow of electricity. Some cement resistors use resistance elements other than wire-wound resistors.

Wire-wound resistors are classified according to the material of the case covering the outside. Besides cement resistors, there are wire-wound resistors, metal-clad resistors, and enamel resistors.

Uses of Cement Resistors

Cement resistors are resistors in electronic circuits that impede the flow of current. They are used to limit current, divide voltage, or detect current, depending on the purpose.

In many cases where cement resistors are used, the temperature of the resistor is high or the humidity is high enough to cause severe deterioration of the resistor. Resistors are also classified according to the power they can use, but cement resistors fall into the medium capacity class (10 W or less) for power circuits.

Cement resistors have excellent heat, moisture, and vibration resistance because the resistors are surrounded by cement. Therefore, most of them are mounted on electronic circuit boards used in outdoor high-power equipment.

Principle of Cement Resistors

Cement resistors are resistance in an electronic circuit, which is expressed as resistance in Ohm’s law. Ohm’s law is expressed by the following equation

V (voltage) = R (resistance) x I (current)

The unit of resistance is the ohm (Ω), which can be found in cement resistor catalogs. In cement resistors, a resistive element, which provides electrical resistance, is encapsulated in cement. When an electric current flows through the resistive element, it generates heat, and its role is to dissipate the heat little by little so that the heat is not easily transferred to the surroundings.

Most resistive elements are wire-wound resistors, but metal oxide film resistors are sometimes used for large resistance values (100 Ω or more). Because of their excellent environmental resistance, they are used outdoors in adverse environments such as high temperatures, high humidity, and intense vibrations.

Most cement resistors are wire-wound type resistors, and their structure is the same as that of a coil. Therefore, they have an inductance component. Because of this effect in the high-frequency band, it is safer to avoid using them in circuits that operate at high speeds, such as high-speed switching, because they may generate unexpected noise.

Other Information on Cement Resistors

1. Advantages of Cement Resistors

The cement used for the casing of cement resistors is non-flammable. Since it does not ignite even at high temperatures, its advantage is that it can be mounted directly on a circuit board. Cement resistors are suitable for use as stable power circuits in harsh environmental conditions.

2. Disadvantages of Cement Resistors

Most cement resistors use wire windings for the resistive elements, which create inductance. When used in high-frequency AC circuits, this results in an increase in impedance. The disadvantage is that these phenomena may cause unexpected noise in circuits operating at high speeds, such as high-speed switching.

Inductance is a phenomenon in which an increase in the current flowing through a coil causes the coil itself to work to reduce the flow of current, and conversely, a decrease in the current causes an increase in the current flowing through it.

Impedance is the ratio of voltage to current in an AC circuit, and it works to impede the flow of current. It expresses the difficulty of current flow and is equivalent to resistance in a DC circuit.