What Is a Pressure Gauge?

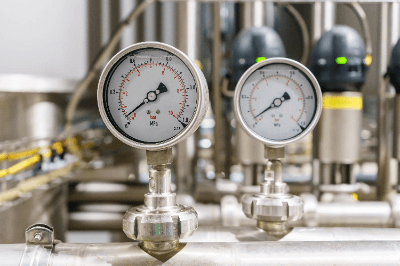

A pressure gauge is a device that measures the pressure of a fluid, such as air or water.

There are different types of pressure, such as constant pressure, fluctuating pressure, and pulsating pressure. And, depending on how the zero point is taken, there can be absolute pressure, gauge pressure, and differential pressure. So it is necessary to select an appropriate pressure gauge depending on the type of pressure to be measured and the output indication method.

Incidentally, a pressure gauge that measures positive gauge pressure is called a pressure gauge, while one that measures negative gauge pressure is called a vacuum gauge.

Uses of Pressure Gauges

Pressure gauges are used in equipment under pressure in factories, plant pipes, and residences and should be selected based on the environment in which they are to be used.

The following are examples of pressure gauge applications:

- Checking the steam volume of a boiler for steam generation in a factory.

- Checking the remaining amount of carbon dioxide in a carbonation tank in a restaurant.

- Measuring the pressure of a compressor.

Principle of Pressure Gauges

Pressure gauges measure pressure by reading the amount of deformation of an elastic body called a pressure-receiving element. There are three types of pressure gauges — Bourdon tube, diaphragm, and bellows — depending on the type of pressure-sensing element, and the principle of each is explained below.

1. Bourdon Tube

Pressure is applied to a metal pipe called a Bourdon tube, causing displacement. The Bourdon tube pressure gauge measures pressure by measuring this displacement, and can do so without the need for external energy such as electricity. Bourdon tube pressure gauges can be further classified into general, compact, sealed, and glycerin-injected types. The Bourdon tube pressure gauge is widely used, but due to its small tube diameter, it cannot be used as is with highly viscous fluids or solids.

2. Diaphragm

Diaphragm pressure gauges measure by converting pressure into an electrical signal through a diaphragm using an element whose resistance value changes according to pressure. Longevity and heat resistance vary depending on whether semiconductors, strain gauges, or thin films are used for the element. Since measurement is made using electrical signals, high-precision pressure measurement is possible. Diaphragm pressure gauges are also suitable for corrosive or highly viscous fluids.

3. Bellows Type

Bellows pressure gauges measure pressure by interpreting the amount of displacement of a bellows-like cylinder with external folds under pressure. Because of its high sensitivity to pressure, the bellows tube type is suitable for measuring relatively low pressures.

How to Use Pressure Gauge

Pressure gauges are used by attaching to the piping through which the fluid to be measured is flowing. For analog gauges, the needle position is read straight from the front of the scale, as with other needle-type analog measuring instruments. In the case of a digital gauge or pressure gauge, the indicated value is read directly.

Since pressure gauges are generally connected directly to piping or other equipment, there are some points to keep in mind when handling them. If a pressure gauge is defective, for example, unintentionally removing it may result in leakage of fluid or injury due to fluid leakage. The pressure in the piping must be reduced during removal. In addition, fluid may remain in the piping or inside the pressure gauge after removal, or a small amount of that fluid may leak out when it is removed. Depending on the fluid being measured, caution may be required during handling.

There are many cases where piping is branched to install a pressure gauge or a branch pipe for measurement. When designing or manufacturing new equipment or machinery that includes piping that handles such fluids, installing a branch pipe for a pressure gauge in advance will minimize the work required when stopping the equipment or machinery and connecting a pressure gauge later.

Selection of Pressure Gauge

There are a variety of pressure gauges on the market intended for different uses. Considerations include:

- Fluid type – Air, oil, water, nitrogen, oxygen, acetylene, propane, refrigerant, etc.

- Gauge pressure notation vs. absolute pressure notation – Normally, we live under an atmospheric pressure of about 0.1 MPa. Gauge pressure is the pressure measured under atmospheric pressure as 0 Pa, and absolute pressure is the pressure measured under vacuum as 0 Pa. Gauge pressure is sometimes referred to as PaG and absolute pressure as PaA.

- Range of pressure to be used – The maximum and minimum pressure that the pressure gauge can withstand, and whether to measure pressure below atmospheric pressure to vacuum.

- Measurement method of pressure gauges – The type of fluid, pressure range, and accuracy that can be used are determined to some extent by the method, such as Prudhomme Kan, diaphragm, and others.

- Measurement accuracy required.

- Pressure gauge size.

- If there is already a branch pipe for mounting the pressure gauge.

- The type of connecting joint.

- The method of mounting the main unit.