What Is a Vacuum Vapor Deposition Device?

A vacuum vapor deposition device is a device that forms a film on an object by vaporizing a substance under reduced pressure.

A vacuum vapor deposition device is a device that forms a film on an object by vaporizing a substance under reduced pressure.

A vacuum vapor deposition device can form a smooth coating on an object, and the thickness and composition of the coating can be controlled.

Uses of Vacuum Vapor Deposition Devices

Vacuum vapor deposition devices can form films of various materials, including metallic materials, such as aluminum and organic/inorganic materials.

Vacuum vapor deposition devices are used for the following applications:

- Optical thin films (antireflection coatings for lenses, special mirrors, etc.)

- Magnetic tapes (audio and video tapes, etc.)

- Semiconductors (organic EL, LED, solar cells, etc.)

- Electronic components (resistors, capacitors, semiconductor integrated circuits, etc.)

- Food packaging materials (e.g. aluminum evaporated film used for snack bags, etc.)

- Analytical applications (sample preparations)

Principle of Vacuum Vapor Deposition Devices

A rotary pump or turbomolecular pump is used to depressurize the chamber, vaporize the material to be deposited, and deposit it on the object at a distance. The reduced pressure removes impurities from the chamber and improves the diffusion of the vaporized material to produce a smooth film with good adhesion.

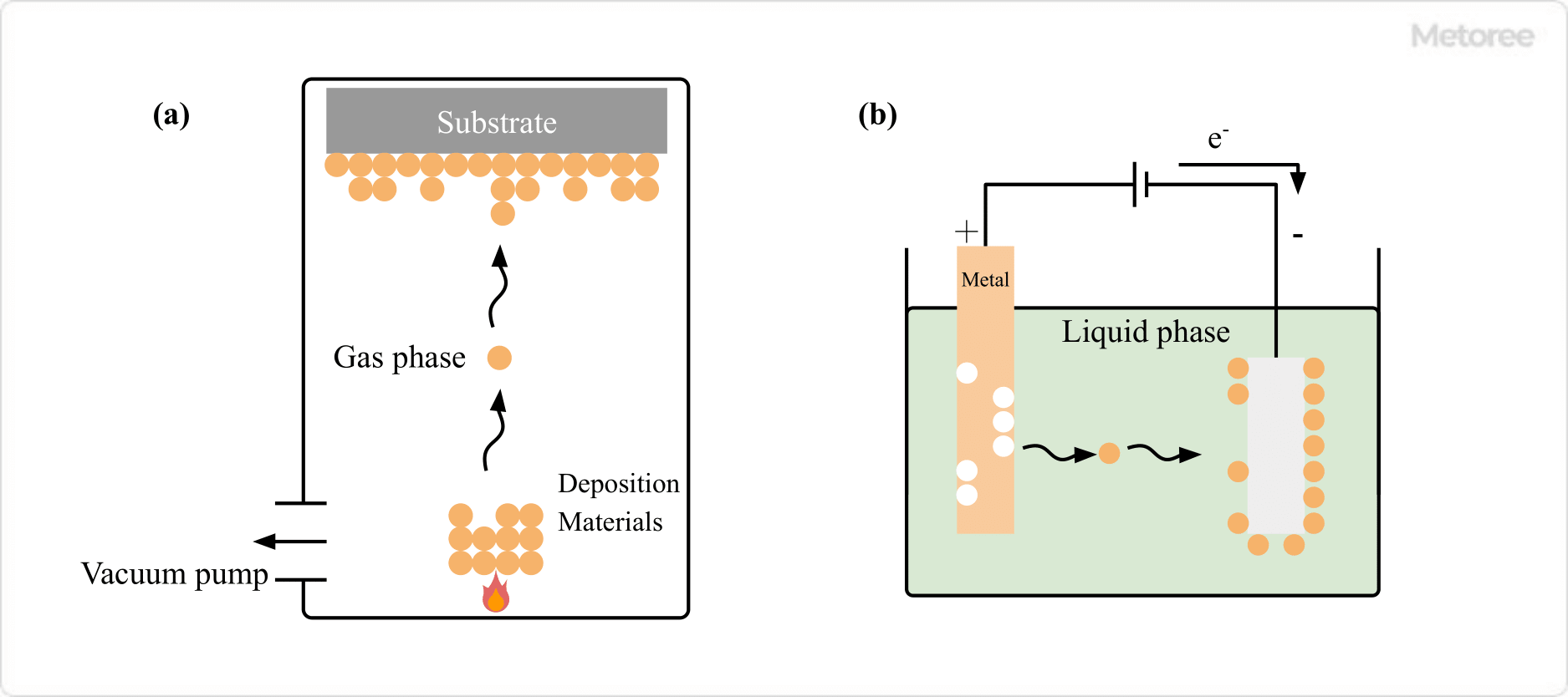

Plating is a well-known method of forming a film on the surface of a material. The difference is in plating, raw materials are supplied from the liquid phase, whereas in vapor deposition, raw materials are supplied from the gas phase.

Types of Vacuum Vapor Deposition Devices

Deposition methods used in vacuum vapor deposition devices can be divided into two types according to the method used to vaporize the substance: physical vapor deposition (PVD) and chemical vapor deposition (CVD).

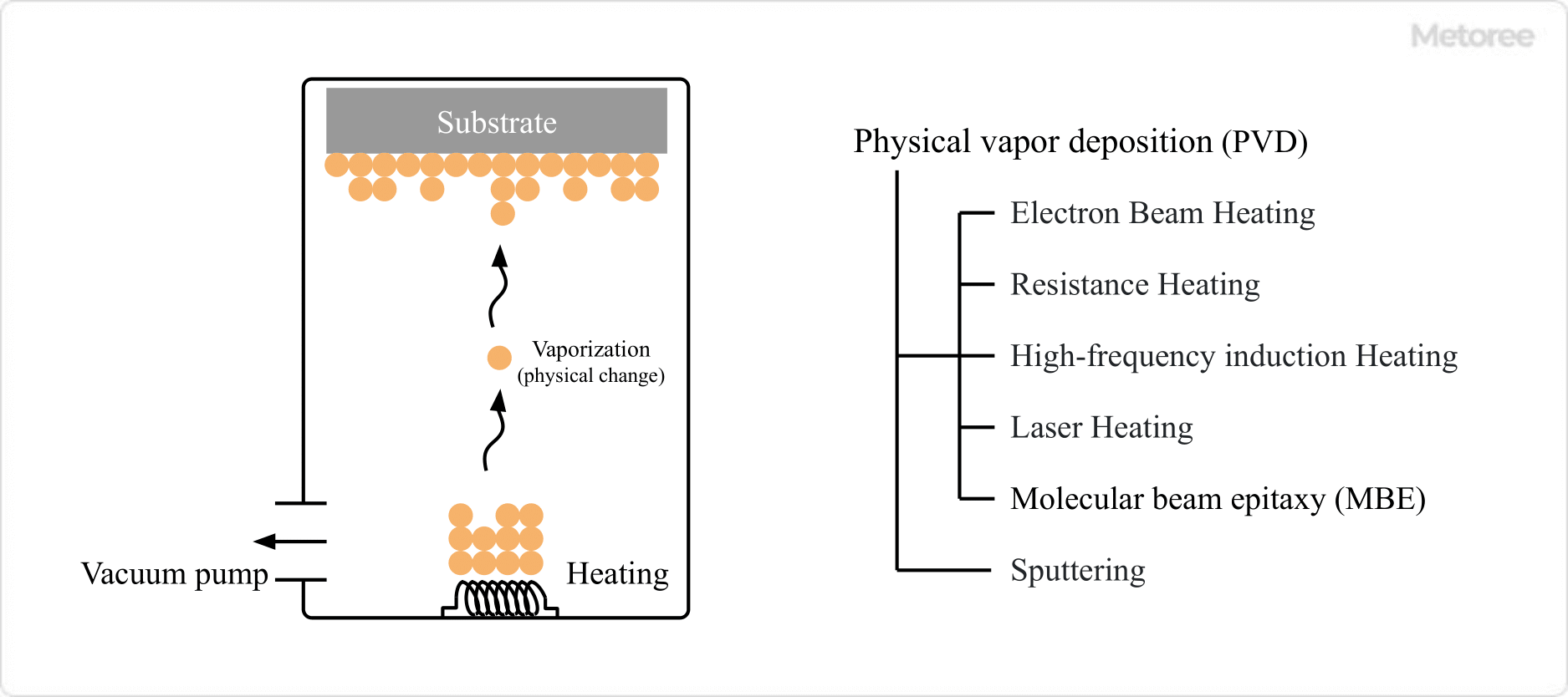

1. Physical Vapor Deposition (PVD)

Physical vapor deposition (PVD) is a method of forming films by vaporizing or sublimating evaporation materials through physical means, such as heating. Heating methods include electron beam, resistance heating, high-frequency induction, and laser.

- Electron Beam Heating

Vaporization is caused by irradiating the evaporation material stored in a crucible made of refractory materials with an electron beam. Electron beams have high energy and can be applied to materials with high melting points. - Resistance Heating

An electric current is applied to a resistor such as tungsten to generate heat, and the evaporation material is placed on the resistor to heat and vaporize the evaporation material. Since it is relatively difficult to raise the temperature, this method is suitable for materials with low melting points. - High-frequency Induction Heating

The evaporation material is placed in a crucible with a coil wound around it, and a high-frequency current is passed through the coil to generate a strong magnetic field. The current generated by the magnetic field and the heat generated by the electric heat resistance rapidly raise the temperature to vaporize the film material. - Laser Heating

By irradiating the deposition material with a laser, high energy is supplied to vaporize the deposition material.

Plasma and molecular beam methods are also used as physical vapor deposition methods.

- Molecular Beam Epitaxy (MBE)

This method uses vacuum deposition in an ultra-high vacuum to align the vaporized molecules in the same direction, allowing for more precise control of film thickness and composition. The growth rate is slow and requires a high vacuum, making it unsuitable for larger equipment and poor for mass production. - Sputtering

When an inert gas, such as argon, is injected into a vacuum and a voltage is applied to the electrode to cause a glow discharge, the plasmaized argon collides with the cathode, repelling atoms and molecules on the cathode. If the object to be deposited is placed on the anode, the repelled atoms are deposited on the surface. Ionization methods include direct current voltage (DC), radio frequency alternating current voltage (RF-AC), magnetrons, and ion beams.

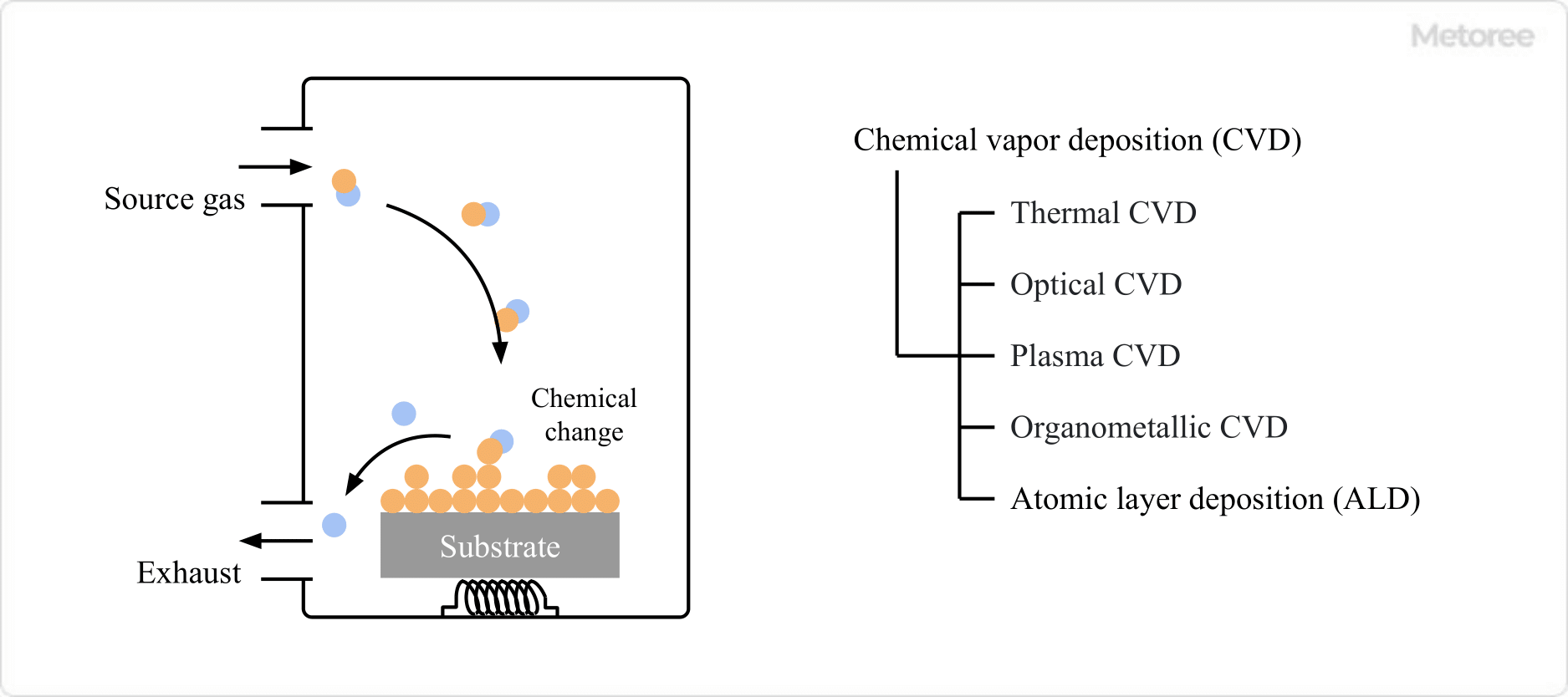

2. Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) is a method of forming films by depositing evaporation materials on an object using chemical reactions or other chemical methods. Typical methods include thermal CVD, optical CVD, plasma CVD, organometallic CVD, and atomic layer deposition (ALD).

- Thermal CVD

This method uses a resistively heated furnace to create high temperatures, through which raw material gases flow to induce chemical reactions to form thin films. Relatively uniform film thickness can be achieved. - Optical CVD

This method uses ultraviolet lamps or laser beams to cause chemical reactions in a low-temperature process to form thin films. Since no ions are generated, there is little damage to the substrate. - Plasma CVD

Plasma CVD is a method in which the reactivity of raw materials is increased by plasticizing them, causing a reaction to the evaporation target to form a film. High-quality films can be formed because thin films are formed at low temperatures. However, the equipment is expensive and maintenance is difficult. - Organometallic CVD

This method uses an organometallic precursor of the metal to be vapor-deposited as a raw material, which reacts on the target to form a metallic thin film. This method is used for the mass production of LEDs and other devices because it can form films at high speed while precisely controlling film thickness. - Atomic Layer Deposition (ALD)

By depositing and replacing multiple types of raw materials one at a time, the materials react in a controlled manner at a fixed location to form a thin film with a controlled structure and thickness.

In addition to the above, vacuum vapor deposition devices of various methods have been developed and are sold. It is necessary to select the appropriate equipment according to the application.