What Is a Resistance Welding Service?

Resistance welding is a technique that utilizes the heat generated by electrical resistance when current is passed through metal. This process involves applying an electric current to the metals to be joined under moderate pressure. The heat generated melts the metal, which then cools and solidifies, forming a strong joint.

Resistance welding is a technique that utilizes the heat generated by electrical resistance when current is passed through metal. This process involves applying an electric current to the metals to be joined under moderate pressure. The heat generated melts the metal, which then cools and solidifies, forming a strong joint.

Distinct from arc and laser welding, resistance welding relies on internally generated heat rather than an external heat source. This method directly melts the base metals, creating a strong bond without the need for solder or other welding aids, thus reducing costs. Moreover, weld marks are typically less noticeable, providing a more aesthetically pleasing finish.

Uses of Resistance Welding Services

Resistance welding is known for its efficiency, often completing processes faster than other welding methods due to the rapid melting of metal under current. This ease of automation, often implemented with robotics, makes it a popular choice in mass-production settings such as home appliances and automotive manufacturing. Its ability to achieve a visually appealing finish also makes it suitable for exterior parts of automobiles and railcars.

However, resistance welding is not suitable for all materials. It requires materials that conduct electricity, are not overly thick, and have suitable properties for resistance welding. Materials like nickel and stainless steel are commonly used in resistance welding services.

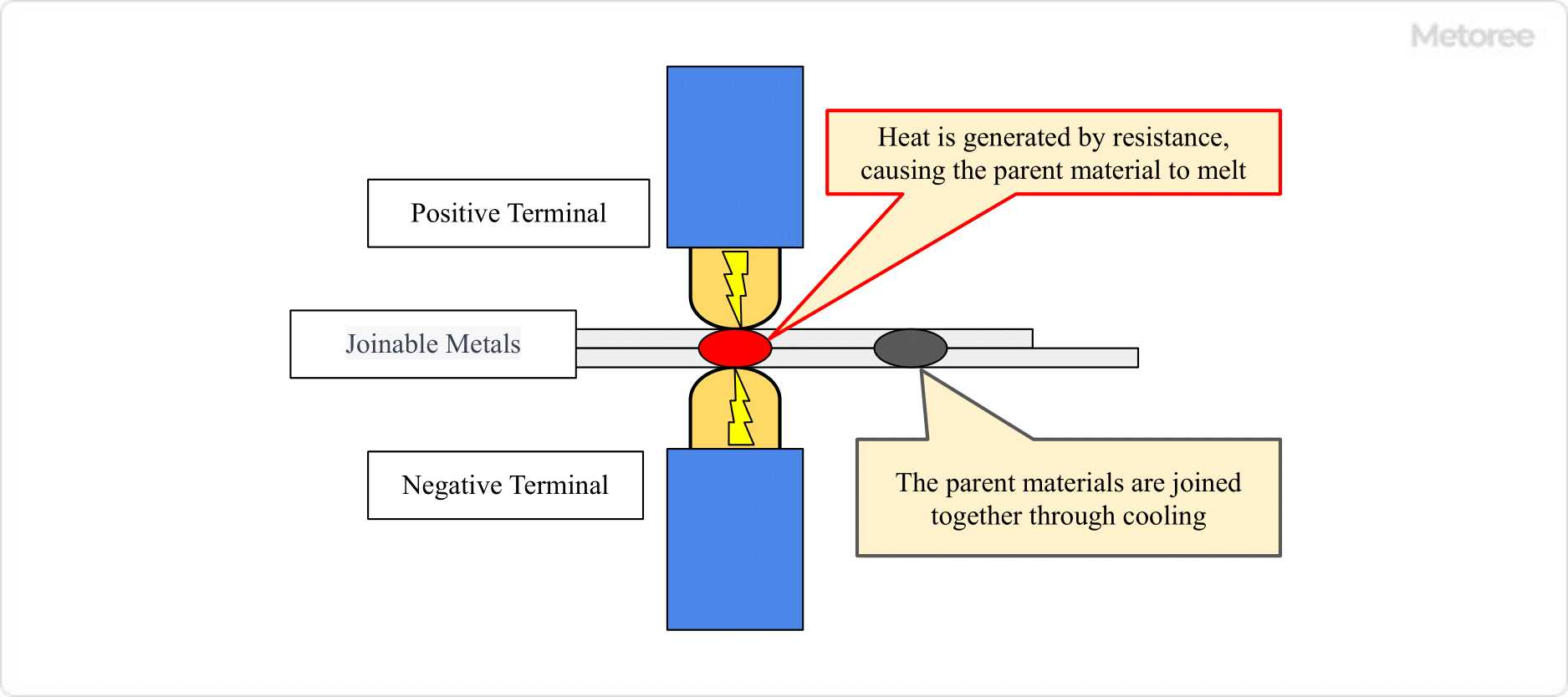

Principle of Resistance Welding Services

Figure 1. Principle of resistance welding

Resistance welding operates on the principle of using heat generated by electrical resistance when current is applied to metal. This process is a reversal of conventional electricity use, where resistance and the resulting heat are typically minimized. In resistance welding, however, this conductive loss is harnessed to melt and join metals.

The process is governed by four key factors, often referred to as the “four major conditions of resistance welding”: applied pressure, welding current, energizing time, and electrode shape. These factors are crucial in determining the quality of the welding.

1. Applied Pressure

Applied pressure refers to the force exerted by the electrode on the metal, facilitating the flow of electric current and affecting the stability of the weld.

2. Welding Current

The welding current influences the rate at which heat is generated and the speed of metal melting, impacting the overall strength of the weld.

3. Energizing Time

Energizing time, the duration for which the current is applied, directly affects welding efficiency.

4. Electrode Shape

The shape of the electrode impacts the distribution of the current and the area of metal melted, affecting the strength and quality of the weld.

Types of Resistance Welding Services

Resistance welding can be primarily categorized into two types: spot welding and seam welding.

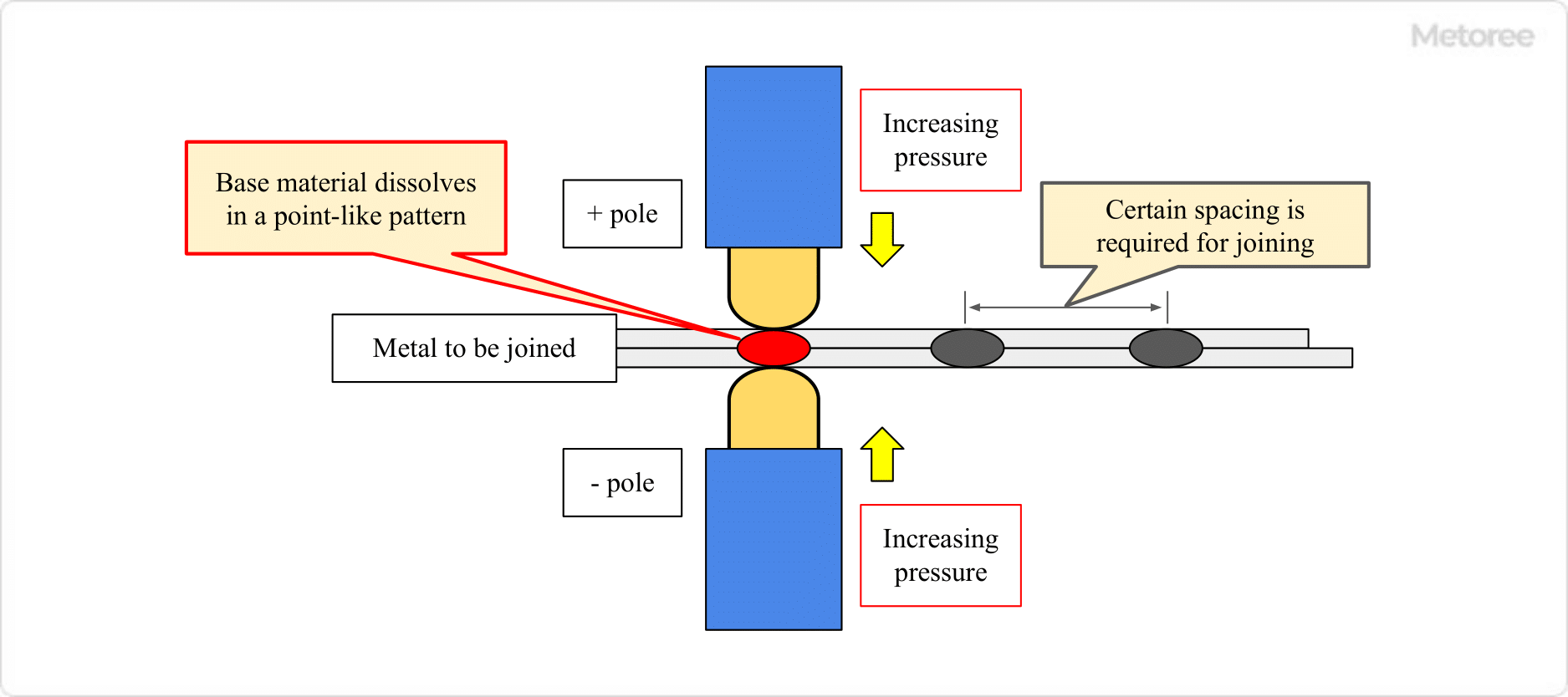

1. Spot Welding

Figure 2. Spot welding

Spot welding involves welding at specific points using two electrodes. This method is effective for joining two metal rods with minimal heat distortion. However, care must be taken to avoid shunting in areas near existing welds.

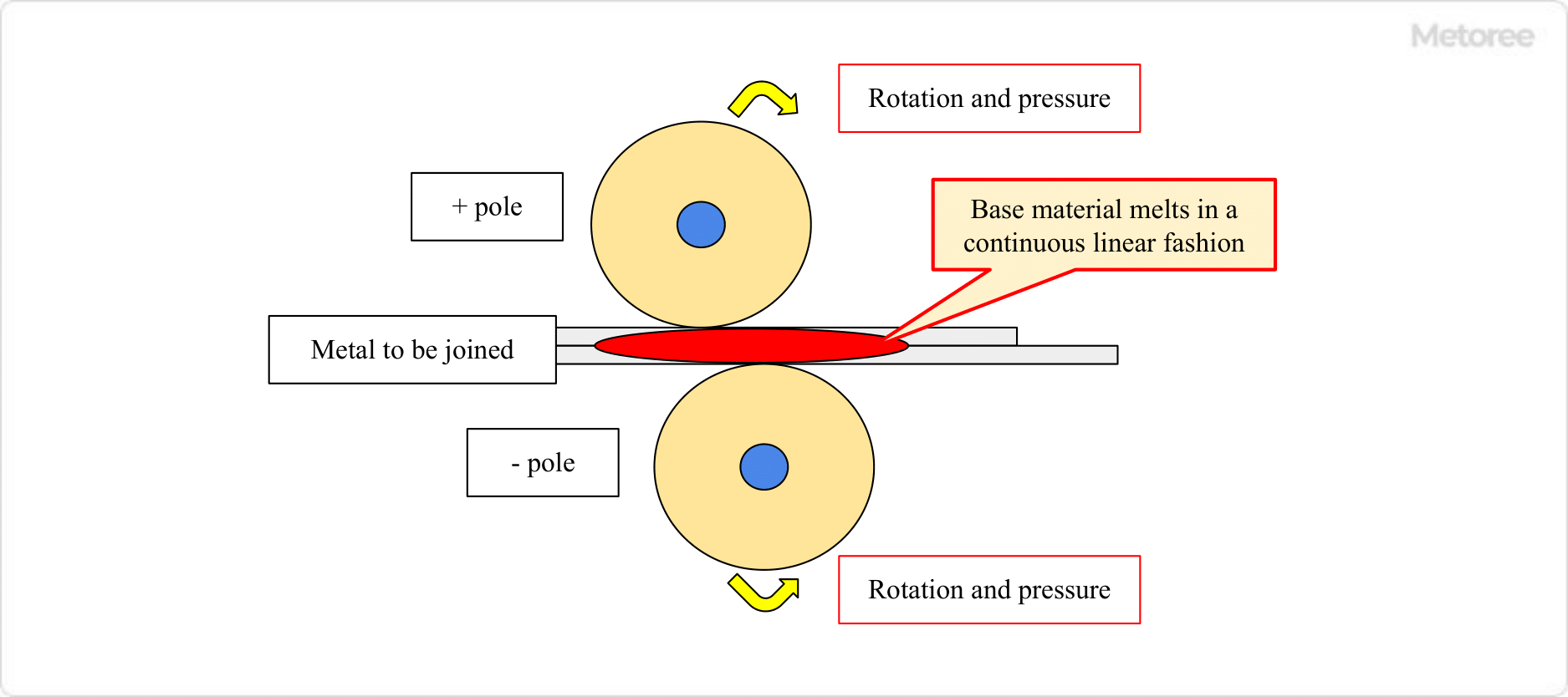

2. Seam Welding

Figure 3. Seam Welding

Seam welding uses roller-shaped electrodes to create continuous, linear welds. While this method is efficient and strong, it can lead to heat distortion in the processed product.