What Is Laser Machinery?

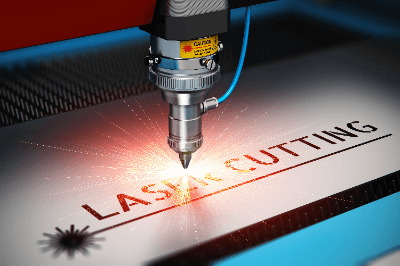

Laser Machinery is a general term for machines that use lasers to perform various processes such as cutting, welding, engraving, marking, and drilling.

CO2 lasers, YAG lasers, fiber lasers, and semiconductor lasers are mainly used for laser machinery.

Laser machining is a non-contact processing type that does not require the use of knives or other tools, and so it is less likely to deform or distort materials due to stress or pressure.

They also require fewer consumables and are easier to maintain. Recently, inexpensive, compact systems designed for home use are also available.

Uses of Laser Machinery

A wide variety of laser machinery is available, of which the following are the main types:

1. CO2 Laser Machinery

CO2 lasers with output power of up to several hundred watts are used for welding, cutting, and engraving. They can weld everything from automobile frames to microfabrication of electronic components. They are also used for cutting thick acrylic sheets and wood, engraving on stone and leather, and cutting paper and fabric.

The output wavelength of 10.6 μm is a wavelength that is also absorbed by glass, so glass can also be processed.

Compared with other laser Machinery, the YAG Laser Machinery can process a wide range of materials and is inexpensive, making it the most standard type of laser machinery.

2. YAG Laser Machinery

The YAG laser, which is often compared to the CO2 laser, has a wavelength of 1.06μm (1060nm) and can process materials that are incompatible with the CO2 laser. Also, the fiber can be used for the optical path, allowing for a compact system design.

3. Fiber Laser

Fiber lasers can process metals such as aluminum, copper, and brass, which are difficult to process because of reflections from other lasers. Also, CO2 lasers require replenishment of the laser medium with carbon dioxide, while fiber lasers require almost no maintenance.

The beam can be easily focused to a small spot diameter, making it suitable for microscopic processing.

Principle of Laser Machinery

Laser light is highly directional, monochromatic, and coherent, and its energy increases further when focused.

In processing machines, the light is usually focused using a special lens. The focused light with increased energy density rapidly heats the surface of the irradiated workpiece. This is because the atoms and molecules within the material vibrate rapidly and emit heat when exposed to light.

This phenomenon is used to instantly dissolve and process the material. Since dust flies when processing metals and other materials, assist gas and dust collectors are used to blow the dust away while ensuring that it does not interfere with the processed surface.

Structure of Laser Machinery

Laser Machinery consists of a laser oscillator, optical path, focusing optics, and drive system. The laser oscillator uses the aforementioned laser. The optical path is the path that transmits light from the laser to the focusing optics, and mirrors and optical fibers are used. The focusing optics collects and irradiates the light. The drive system is the stage or jig on which the material to be processed is placed.

Appropriate types are designed according to the processing of the material and the oscillation speed of the laser.