What Is a Shot Blasting Service?

Shot blasting service is a surface treatment method in which a projectile, such as sand, glass balls, steel balls, or ceramic material, is shot onto the surface of a workpiece, such as metal, at high speed.

It is sometimes simply referred to as blasting. The main purpose of shot blasting service is to inhibit the progression of rust and improve the durability of the coating to maintain its quality for a long time. Shot peening has the following three effects:

1. Cleaning to Remove Rust and Dirt

The first effect is to remove rust and scale from the surface of the product being treated. When repainting, it is sometimes done to remove old paint and clean the surface.

2. Surface Preparation Prior to Painting or Bonding

Shot blasting service is used as a surface preparation before painting, plating, or gluing. The rougher the surface by shot blasting service, the better the adhesion to the paint, plating, or adhesive.

3. Improvement of Durability

Work hardening occurs in metal materials when they are processed. Shot blasting service can improve the durability of parts by work hardening in a narrow area of the surface layer.

Uses of Shot Blasting Services

Shot blasting services are used in the iron-working, shipbuilding, and construction industries. These purposes are performed on components that must be protected from rust and other corrosion over a long period of time.

For example, shot blasting services are used for aggregates that support the structure of ships, bridges that span rivers and the sea, and buildings such as condominiums and buildings that must be highly resistant to sea breezes, sea water, and wind and rain. Shot blasting services are also applied to power plants, gas tanks, offshore structures, and a wide range of other applications.

Principles of Shot Blasting Services

There are two principles of shot blasting services: removal of mill scale and improvement of adhesion to the paint.

1. Mill Scale Removal

Mill scale is a layer of iron oxide on the surface of steel. If paint is applied with this mill scale remaining, rust will form from underneath the paint. Therefore, shot blasting services are performed before painting to remove mill scale to prevent rust from progressing under the paint.

2. Improved Adhesion to Paint

Shot blasting services improves the adhesion between the steel and the paint by creating a wedge effect on the surface.

Types of Shot Blasting Services

There are two types of shot blasting services, manual and automatic, depending on the method of operation.

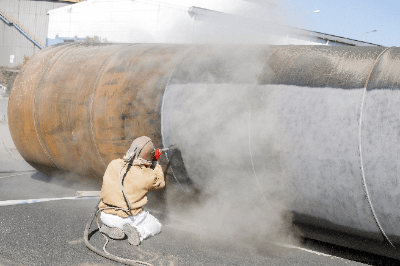

1. Manual Type

Manual shot blasting is performed with a hand-held air gun. It is possible to apply shot blasting services to the entire surface of large workpieces that are difficult to automate or have complex shapes.

2. Automatic Type

The automatic type is suitable for processing large quantities of non-large workpieces. Products are placed in the automatic shot blast machine, and a large quantity of products are processed at one time. Products can be supplied by roller conveyors, by suspending products on hangers, or by rotating tables. Appropriate selection is necessary depending on the shape of the products to be processed and the number of products to be processed.

Other Information on Shot Blasting Services

Difference From Shot Peening

Shot peening is a surface treatment similar to shot blasting services. Shot peening is another surface treatment technique in which media is projected onto the surface of the product.

The difference between shot blasting and shot peening is the purpose of the treatment. While shot blasting services are primarily aimed at improving appearance and corrosion resistance functions, such as inhibiting the progression of rust, the purpose of shot peening is to improve material strength.

A metallic material undergoes a phenomenon called work hardening, in which plastic deformation causes it to become harder and material strength to increase. Shot blasting services also generate residual compressive stress on the surface, which increases the strength of the product. As a result, the fatigue strength, wear resistance, and stress corrosion cracking resistance of parts are improved.

For example, in automotive parts, the strength and wear resistance of gears that transmit the output of engines and motors are improved. Shot peening is used as a strengthening method to make gear parts smaller and lighter than before or to apply them to engines with even greater output.