What Is a Press Service?

A press service is a process of deforming soft metals and other materials using a press machine.

A die is pressed against the material and strong pressure is applied by the press machine to deform it into the desired shape. The pressing mold is used by cutting and turning alloy steel such as pre-hardened steel and stainless steel.

A press service is characterized by the fact that the metal is deformed and formed in a single press by applying strong pressure. The greatest advantage is that a large number of pieces can be mass-produced at once in a short time because the processing time is extremely short.

Presses also require an initial investment and are recommended when products need to be mass-produced over a long period of time.

Uses of Press Services

Press services are used for the mass production of a single part.

It is often used to form familiar metal products because it is a simple and easily mass-produced process. Many of the frames of automobiles and home appliances are made of metal, and most of the parts are press-formed because they can be processed to the same shape with high precision.

Generally, it takes 3 to 6 months to produce a single die, including fine adjustments to improve dimensional accuracy during processing. In order to accurately shape complex bends and curved surfaces, such as those found in the outer panels of automobiles, it is necessary to press a single sheet multiple times using multiple molds.

Press services are not suitable for parts used only in small quantities because of the time and cost required to prepare the dies.

Principle of Press Services

The principle of press services is to cause plastic deformation of the metal to be formed by pressing a die against it while applying high pressure with a press machine.

When a load is applied to a metal, a force is generated that tries to return the metal to its original shape. This is called plastic deformation. By causing plastic deformation in a press machine all at once, large quantities can be produced in a short time with high accuracy.

Types of Press Services

There are three major types of press services:

- Shearing

- Bending

- Drawing

These three processes may be combined to perform a series of processes on a single workpiece of metal.

1. Shearing

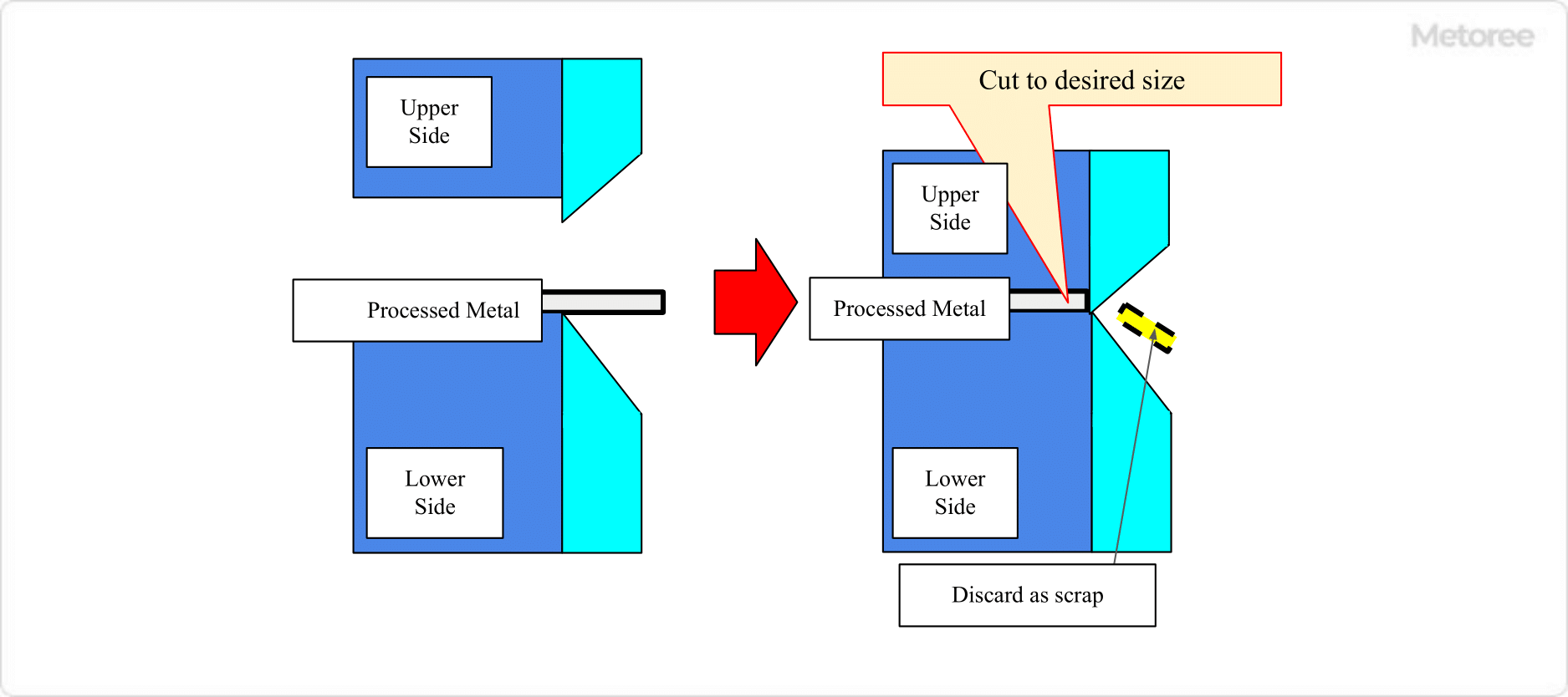

Figure 1. Shearing

Shearing is a process of cutting a workpiece to a desired size or shape by preparing two blades on the top and bottom of the workpiece and pressing them together at once. As a processing method that applies shearing processing, there is also a processing method called punching processing in which a target mold is punched like a cookie cutter to cut out the desired shape from a flat plate-shaped processing agent.

2. Bending Processing

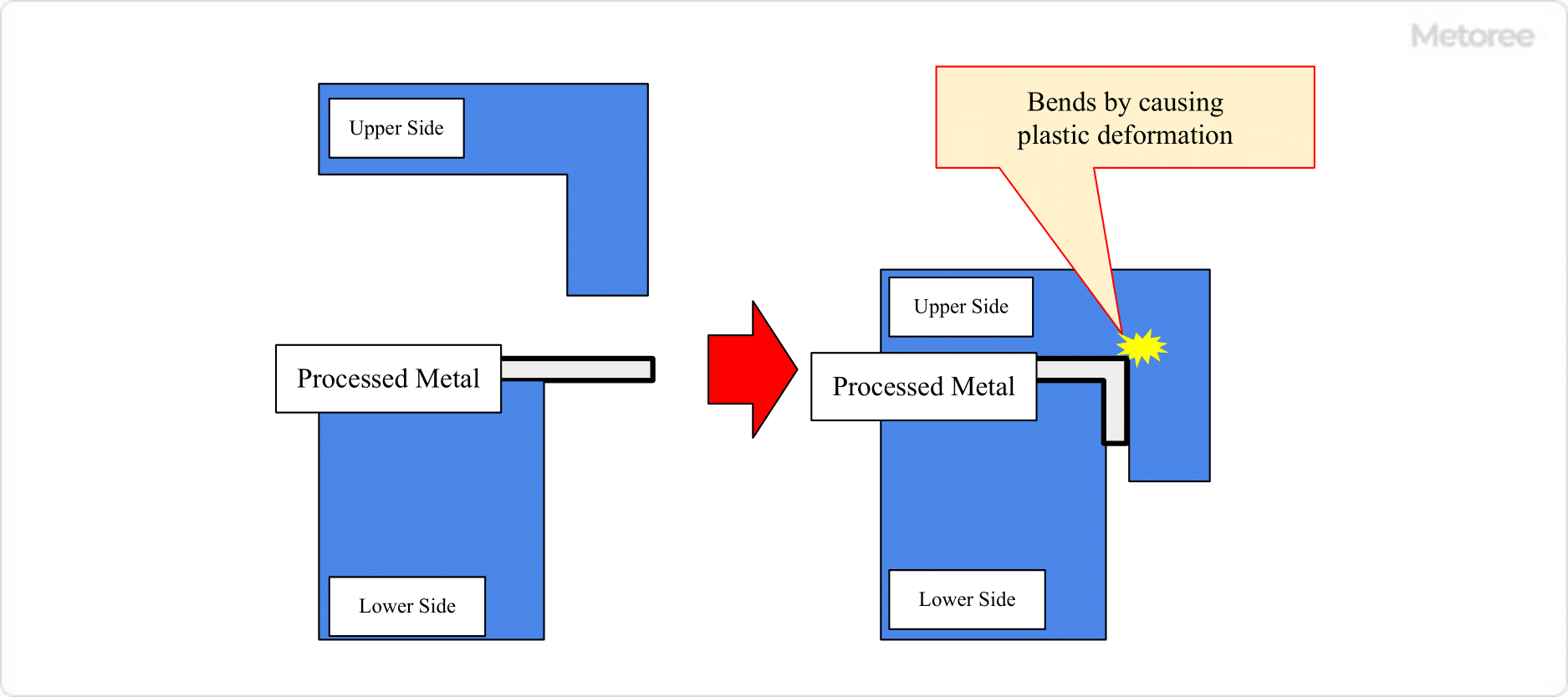

Figure 2. Bending process

Bending is a process for bending metal by pressing a V- or L-shaped bending die against the material to be processed using press services. Since many metals are hard and cannot be bent without strong pressure, it is important to bend them with a press machine that can apply strong pressure at once.

The use of press services allows the angle of bending to be set precisely, but there is a limit to the angle of bending that can be set because undercutting may occur, where the product cannot be pulled out of the die after processing.

3. Drawing Process

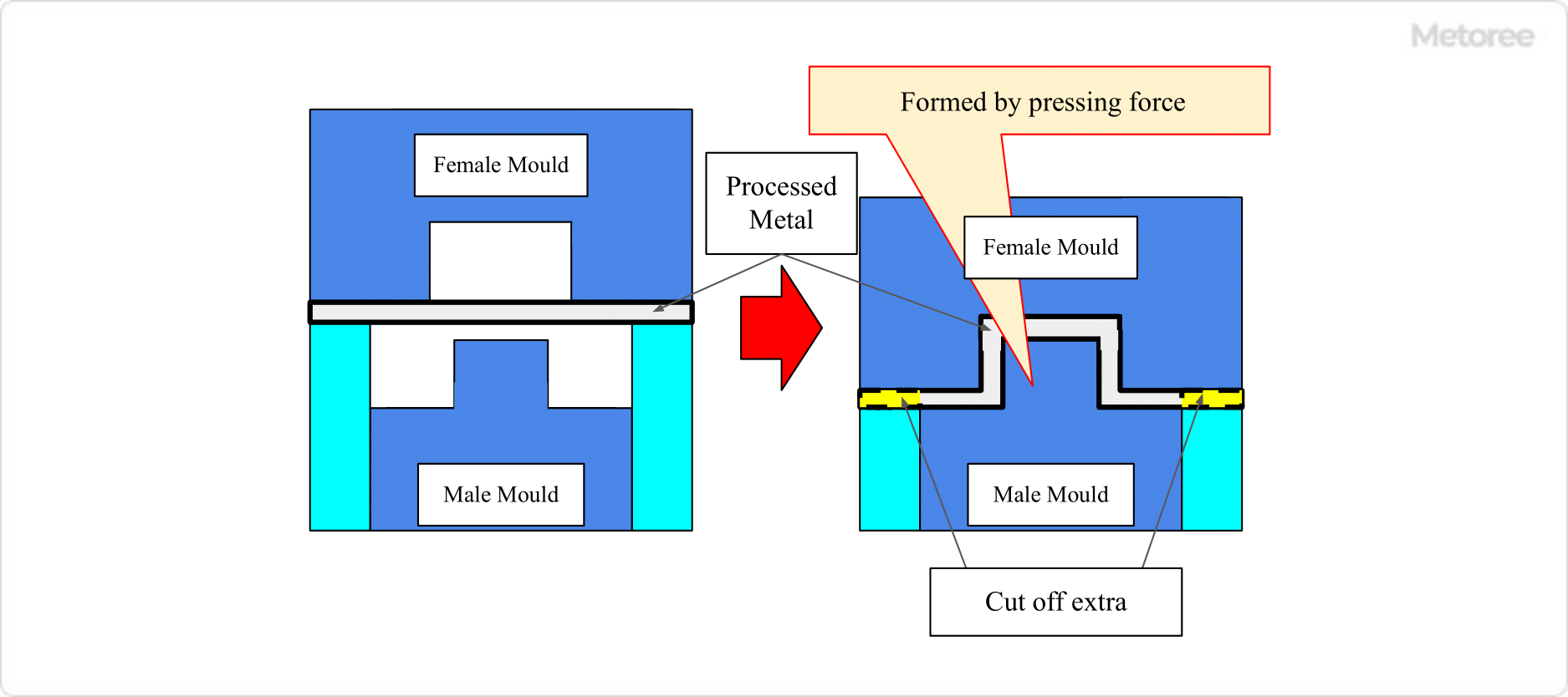

Figure 3. Drawing process

Drawing is a processing method in which a flat sheet of metal is deformed into a container shape by preparing a concave part of the desired shape on the receiving side of the press services and a convex part on the extruding side and applying it to the press machine.

Since the concavities and convexities are aligned to form the desired shape, right-angle bending cannot be handled, but a three-dimensional shape with a rounded edge can be formed. Compared to bending, it is necessary to hold down the outer circumference firmly because it is pressed against the mold, so the material is required to be one size larger, and the material cost tends to be higher.

These processing methods can be combined to create more complex shapes.

Other Information on Press Services

Machines Used in Press Services

1. Types of Presses by Power Source

- Mechanical Press Machine

A mechanical press is a machine that presses by rotating a motor and moving a slide up and down. - Hydraulic Press Machine

A motor-driven pump applies pressure to the oil in the cylinder to move the piston and press the slide in an up-and-down motion. Although it can be processed in a wide range, it is not suitable for mass production because the processing speed is slow. - Hand Press Machine

A hand press is a machine that presses by manually moving a handle or lever.

2. Types of Presses by Shape

- C-type Press

This is a versatile press machine that looks like the letter C when the machine is viewed from the side. - Straight Side Press Machine

This is a press machine with a press force exceeding 2500 kN. - Transfer Press

This press machine is used for line press services. - Servo Press

Driven by a servo motor, this press is capable of complex, high-precision processing.