What Is an X-ray Inspection System?

An X-ray Inspection System is a device that irradiates an object with X-rays and measures and analyzes the X-rays transmitted through the object to detect foreign matter or damage inside the object without destroying it.

It is also possible to identify elements and accurately measure the content rate of hazardous substances.

Uses of X-Ray Inspection System

X-ray Inspection Systems are used not only in the medical field and in the manufacturing and processing of food and electronic components, but also in the construction and aviation industries. Typical applications are as follows

- Medical field: Radiography, CT scans, etc.

- Manufacturing industry: detection of foreign objects, product inspection, etc.

- Construction industry: non-destructive testing of concrete, etc.

- Aviation industry: baggage inspection at airports, etc.

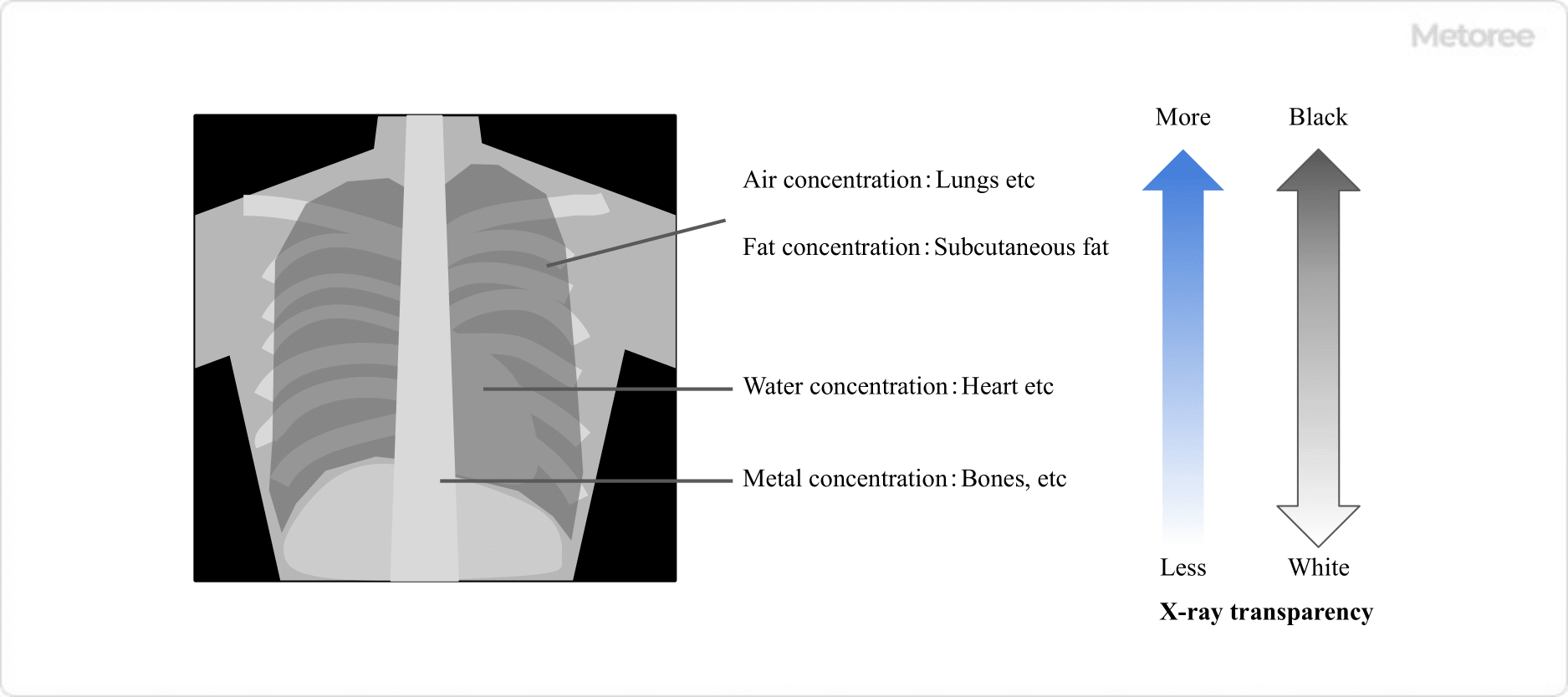

In the medical field, X-ray Inspection Systems produce white contrast in areas where the intensity of transmitted X-rays is high, and black contrast in areas where the irradiated X-rays are attenuated. The intensity of transmitted X-rays is determined by factors such as the atomic number, density, and thickness of the material. The higher the atomic number, the higher the density, and the thicker the material, the more the irradiated X-rays are shielded and the intensity of transmitted X-rays decreases.

For example, in the case of radiography of the human body, the contrast is as follows

- Highly transparent (black): air (lungs, digestive tract gases) and fat

- Medium (gray): water (pleural fluid, ascites, urine), soft tissue (brain, abdominal organs, muscles, etc.)

- Low permeability (white): bone, calcification (gallstones, kidney stones, etc.), metal (artificial joints, etc.)

Using this fact, technology has been developed to convert CT images into 3-dimensional color images.

Principle of X-Ray Inspection Systems

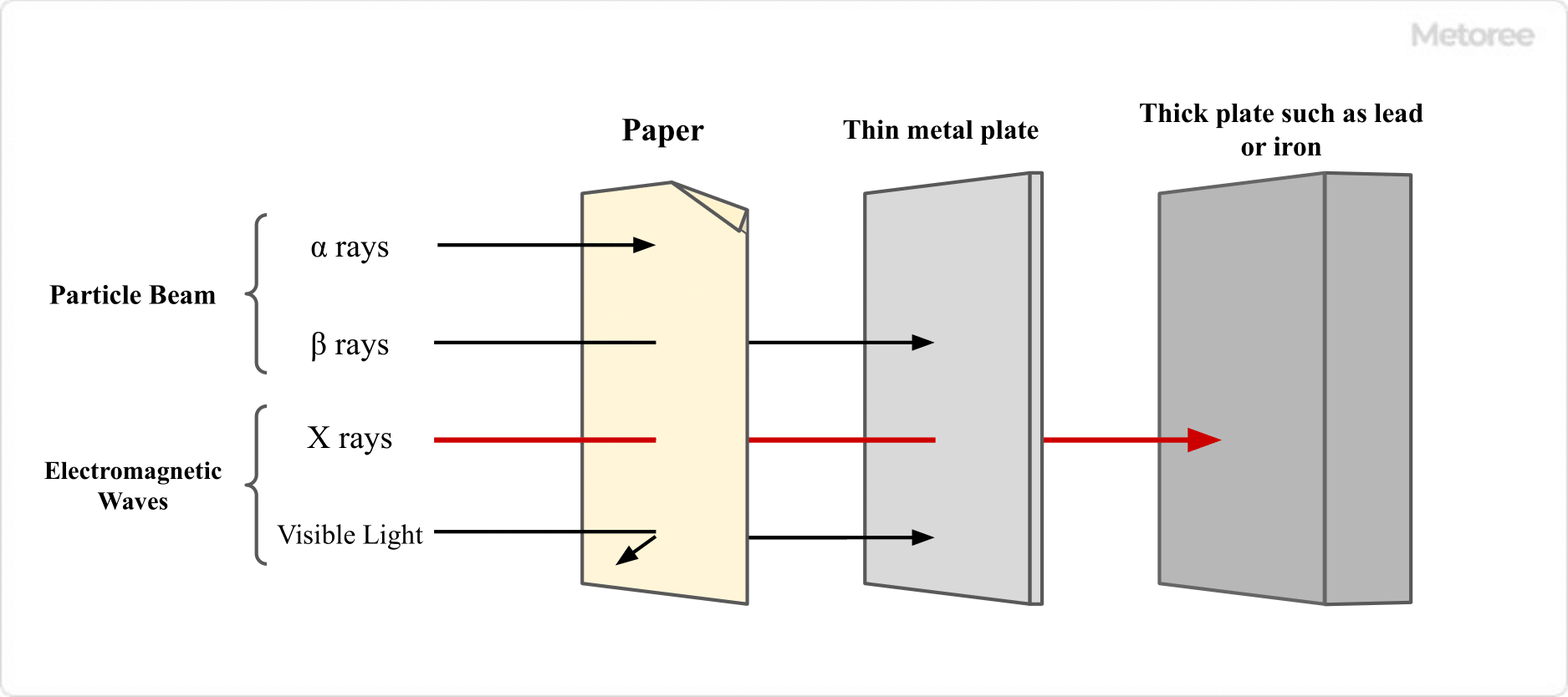

X-rays are electromagnetic waves with wavelengths of about 10-3 nm – 10 nm, and are a type of radiation. There are several types of radiation, including α-rays, β-rays, γ-rays, X-rays, and neutron rays, etc. Unlike particle rays such as α-rays, X-rays are electromagnetic waves with a short wavelength and can penetrate most materials.

When X-rays are irradiated to a material, some of the X-rays collide with electrons in the material and interact with them, causing absorption and scattering phenomena. Among the irradiated X-rays, the X-rays that do not cause these phenomena are the transmitted X-rays that penetrate the material.

Structure of X-Ray Inspection System

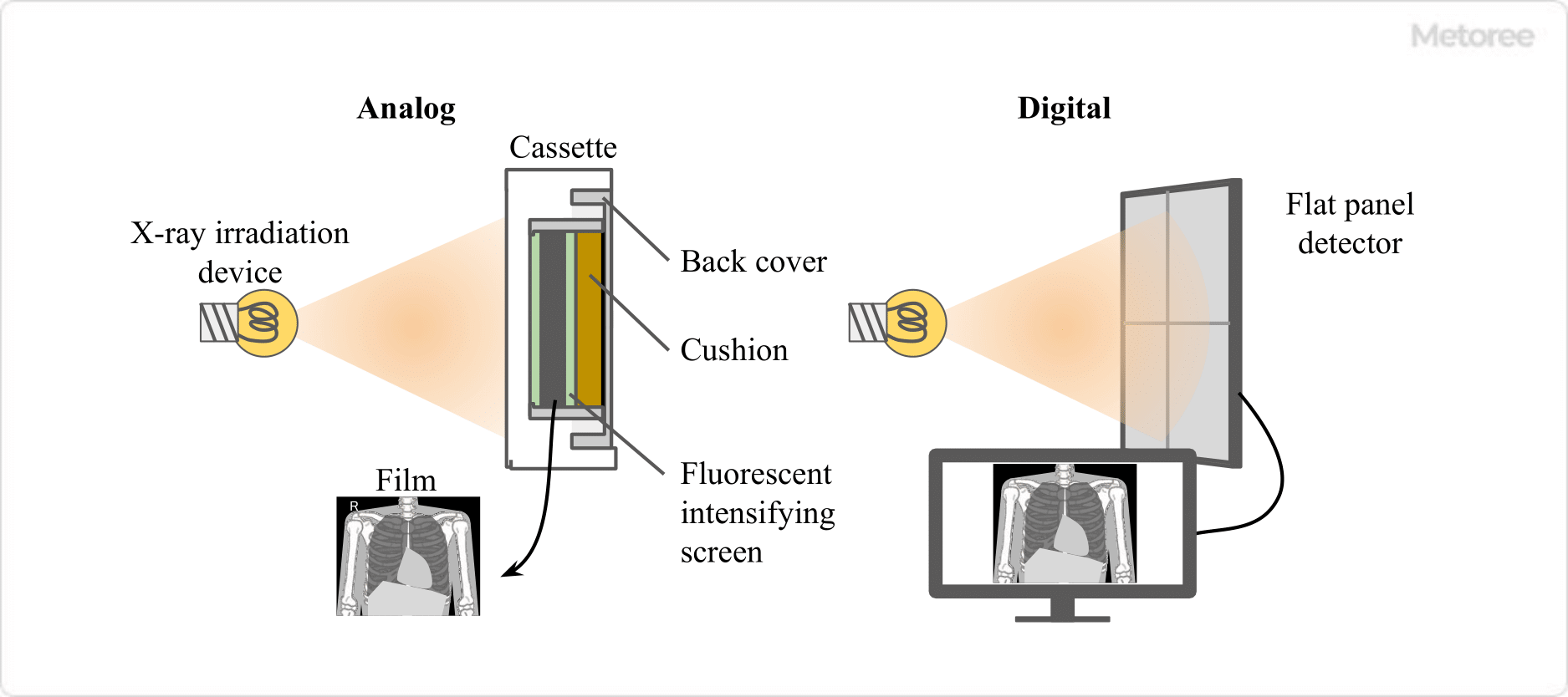

The X-ray Inspection System consists of an X-ray irradiation system and an X-ray photosensitive section. The X-ray photosensitive section is placed between the irradiated object and a film is used to contrast the intensity distribution of the transmitted X-rays. The conventional X-ray photosensitive section consists of a photosensitive film clipped with fluorescent sensitized paper and placed in a case called a cassette. Today, most X-ray Inspection Systems are digital, using Imaging Plates (IP) or Flat Panel Detectors (FPD) instead of photosensitive film.

Types of X-Ray Inspection Systems

X-ray Inspection Systems can be divided into the following main types, which have evolved over time

1. X-Ray TV Systems

X-ray TV systems capture the internal conditions of the body in real time as moving images and allow observation on a TV image. Contrast agent is injected into organs and blood vessels, and the images can be taken while checking how the contrast is formed. It is also possible to observe and treat patients using an endoscope or other equipment while fluoroscopically observing them with an X-ray TV system.

2. CT Baggage Inspection

The common method of baggage inspection at airports is to irradiate X-rays vertically and observe the inside of the baggage. This system is expected to alleviate congestion at baggage checkpoints at airports, since baggage can be inspected without opening the baggage. The system has been introduced at some airports in Japan and abroad.

3. Miniaturization of X-Ray Inspection System

With the development of portable X-ray sources and the digitization of photosensitive areas, a variety of portable X-ray Inspection Systems have been developed and marketed today. They are mainly used as nondestructive inspection equipment at factories and construction sites. They can check for internal cracks, fissures, corrosion, and other abnormalities without destroying the inspection target. X-ray Inspection Systems are often used for completion and periodic inspections at factories and construction sites, and their applications are expanding due to their miniaturization, such as underwater inspections and attachment to self-propelled robots.

Other Information on X-ray Inspection Systems

Qualifications for X-Ray Inspection System

In order to use X-ray Inspection System, a person who has obtained the “X-ray Operation Chief License” must be appointed as the responsible person. The holder of this license is responsible for X-ray-related maintenance work, and his/her duties include checking the restricted areas to prevent radiation hazards, X-ray Inspection System inspection, and X-ray irradiation adjustment and management.

To obtain the certification, the candidate must take the following four subject tests and pass with a total score of 60% (40% in each subject) or higher.

- Knowledge of X-ray management

- Knowledge of X-ray measurement

- Effects of X-rays on the human body

- Relevant laws and regulations

This license is not renewable and can be held permanently once passed.