What Is a Machining Center?

A machining center is a numerically controlled (NC) machine tool that performs various types of machining without the need to change the workpiece.

In addition to the main spindle, which is used to mount tools and provide rotational motion, the machining center consists of an ATC (Automatic Tool Changer) and an index table for fixing the workpiece at various angles.

Uses of Machining Centers

Machining centers are used to process metal, plastic, glass, and other materials, including molds, which are indispensable for molding. Since various tools can be changed automatically, machining with tools such as milling, end milling, drilling, boring, and tapping can be performed in a single process.

In terms of machining freedom, the addition of two rotational axes to the conventional three axes of length, width, and height enables machining with five degrees of freedom. This eliminates the need to lift the workpiece and allows for the production of highly accurate parts.

Principle of Machining Centers

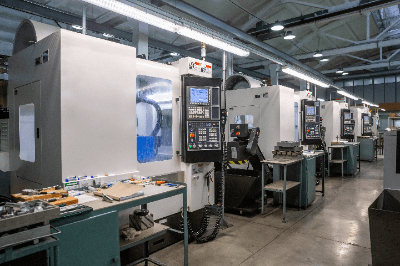

Machining centers are classified into three types: vertical machining centers, horizontal machining centers, and double-column machining centers.

Vertical machining centers have a vertical spindle, and the workpiece is machined from above. Vertical machining centers are compact and the most widely used type. During machining, cutting chips remain on the workpiece and tend to damage the tool’s cutting edges. Measures such as adjusting the tool rotation speed and the amount of cutting oil are necessary to facilitate chip removal.

In the horizontal type, the spindle is horizontal to the ground, and the workpiece is machined from the side. Cutting debris falls to the bottom of the workpiece for easy discharge. Also, a pallet changer that automatically transfers parts can be installed, allowing parts to be machined continuously without the use of human hands, making it suitable for mass production.

The gate type is shaped like a gate when viewed from the front and is suitable for processing large products because the table on which the workpiece is placed is wide and long.