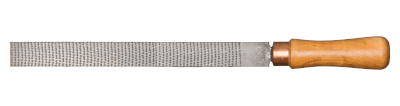

What Is a File?

A file is a tool for grinding an object. More specifically, a file is a tool made of carbon or alloy tool steel with a cutting edge called a “grain” that is swaged or machined into the tool and heat-treated. Filing is the process of machining by grinding flat, curved surfaces and corners with these tools.

The file is selected according to the type of grinding work to be performed on the object. The grit sizes are rough, medium, fine, and oil grit, with subsequent grits representing finer grits.

Uses of Files

Files are used to grind the surface of an object to obtain flatness and precision or to polish a surface to give it a glossy finish.

There are several different types of file grits, which are used according to the material, and the required finishing accuracy.

As an example of how to use different types of files, let us consider the task of creating flatness on the surface of a piece of machinery or equipment.

First, in order to prepare a rough surface initially, a large amount of grinding is done using a rough duplex file. Then, a medium- or fine-grained single file is used to grind the surface finely. In this way, the entire surface is first ground to a rough finish with a large grind and then ground with a fine grind to produce flatness accuracy efficiently.

Characteristics of the Files

Files are characterized by the fact that they can only grind the part that is in contact with the object and to which force is applied. This means that the application of force during grinding must be constant to achieve a clean finish.

For example, consider the operation of using a long, flatboard file to grind the corners of a table into a round shape.

To grind, place the tip of the board files against the corner of the table and move the files as if pushing the handle out. At this time, the corner of the table that is in contact with the board files moves with the pushing motion. The closer the corner of the table is to the handle, the stronger the force applied to the contact surface between the table and the files. This happens because of the principle of leverage between the corner of the table and the board files.

Thus, even if you think you are grinding with the same force, the force applied to the workpiece varies depending on the position of the files in contact with the workpiece. In this case, the corners of the table are not ground with a constant force, resulting in an irregular shape.

Considering that the force applied to the workpiece changes during the grinding process, simply adjusting the force applied so that the same force is always applied will improve the finish of the grinding process.