What Is a Spinner

A spinner is a machine that spins raw materials (natural fibers such as wool or chemical fibers) into yarn. Natural fibers are often spun from a single raw material, while synthetic fibers are sometimes spun from a mixture of natural and chemical fibers.

Spinning is generally done in the following order, depending on the raw material: blended cotton, combed cotton, woven cotton, spun cotton, spun yarn, and wound yarn.

Natural fibers are often spun from a single raw material, while synthetic fibers are sometimes spun from a mixture of natural and synthetic fibers, depending on the application.

Uses of Spinners

In spinning, natural and synthetic fibers are mixed in the blended cotton process, and the mixture is made to a uniform thickness, rolled, and then carded in the next process to make thicker twine.

In the kneading machine, the material made in the previous process is stretched while being homogenized, and then further stretched in the next coarse to make coarse yarn with a thickness of 5 to 8 mm dia.

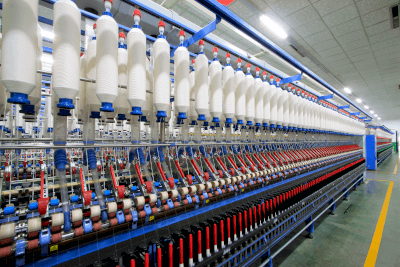

The coarse yarn is further stretched and twisted to increase its strength, and then it is wound onto a bobbin to be made into a tube yarn. In the final winding machine, the yarn is finished and spun into cylindrical or conical shapes to complete the process.

Features of Spinners

The machines used and their purposes differ depending on the manufacturing process.

- Blended spinners

After removing dust and other debris from the inside of the cotton, it is “wrapped” and formed into a sheet. - Carding machine

The mixed fibers of the wrap are then combed to align the fibers in a certain direction before being turned into yarn, which is then stretched and bound into a thick thread called a “sliver”. However, it remains fragile, easily breaking when pulled. - Kneading machine

About 8 to 10 slivers are bound together, and their thickness is adjusted as they are stretched. The result is called a “kneaded shino sliver,” which is still weak and will break if pulled. - Rough spinners

This machine stretches and twists the kneaded shino sliver to produce a coarse yarn, and finally has a little strength. - Spinners

The coarse yarn is further twisted while being stretched and is finally completed as a tubular yarn, which is then wound onto a bobbin.

In the final “rewinding process,” the yarn wound on the bobbin is made into cylindrical “cheese” or corn-like “corn,” depending on the intended use, and the spinning process is completed.