What Is a Pneumatic Valve?

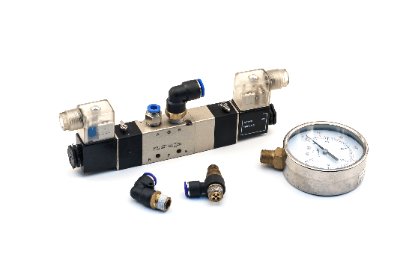

Pneumatic valves are devices that control air pressure in systems or use air pressure to operate actuators. This article focuses on pneumatic relief valves/safety valves and pneumatic actuators/pneumatic valves. Pneumatic relief valves are designed for compressed air systems, including air compressors, to safeguard against excessive pressure by releasing air when the system’s pressure approaches a critical level.

These valves are crucial for maintaining safe pressure levels in compressed air applications. Pneumatic actuators, on the other hand, are valves that utilize pneumatic force to switch between open or closed states, providing a simple, efficient way to manage airflow with significant driving force.

Uses of Pneumatic Valves

1. Pneumatic Relief Valve

Used in compressed air systems to regulate or release excessive pressure, pneumatic relief valves prevent potential damage to the compressor and other system components by mitigating pressure spikes. These valves are compact and can be easily integrated into the system through a threaded mounting port.

2. Pneumatic Actuator

Pneumatic actuators play a vital role in fluid handling systems by controlling the start and stop of flow using high-pressure air. They are pivotal in automating valve operation for efficient fluid management.

Principle of Pneumatic Valves

1. Pneumatic Relief Valve

The construction of a pneumatic relief valve includes a nozzle for air intake, a disc acting as a seal, and a spring to maintain pressure on the disc. The spring tension can be adjusted to set the air pressure threshold for safety. When the system pressure exceeds this threshold, the air pressure forces the disc up, allowing excess air to escape and reduce the pressure.

2. Pneumatic Actuators

Pneumatic actuators use high-pressure air to move valves for fluid control. The influx of high-pressure air moves internal cylinder components, translating this motion into valve operation via rack and pinion gears.

Other Information on Pneumatic Valves

1. Common Causes of Pneumatic Relief Valve Failure

Despite their reliability, pneumatic relief valves can fail due to dirt, wear, or damage to their components. Issues such as nozzle or disc damage can lead to air leakage at non-critical pressures. A compromised spring may fail to maintain the necessary pressure on the disc, resulting in unwanted air release.

2. Common Causes of Compressed Air System Failure

A malfunctioning pressure switch, rather than the pneumatic valve, often causes unexpected pressure issues in compressed air systems. The pressure switch regulates the operational pressure range of the compressor, and its failure can lead to air leakage. A professional inspection of the entire compressed air system is recommended to identify and rectify such issues.