What Is a Thickness Gauge?

A thickness gauge, also known as a skimming gauge, is a tool designed to measure the size of gaps between objects that are difficult to measure with standard measuring instruments like rulers and micrometers. While calipers are generally used for measuring dimensions, thickness gauges are utilized in situations where calipers are not applicable.

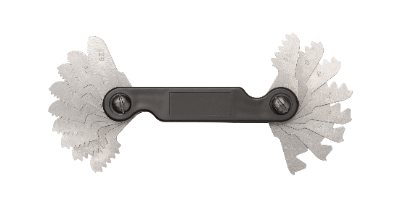

These gauges are particularly useful in scenarios where the size of a gap, such as in a gasket, cannot be determined visually. A thickness gauge consists of multiple thin metal sheets of varying sizes, which are stacked to measure the gap size.

Uses of Thickness Gauges

Thickness gauges are employed to measure gaps in products where calipers and other measuring instruments fall short. The gauge measures the skimmer dimension by overlapping thin metal sheets, known as leaves, of a specific thickness. The leaves in a thickness gauge, standardized in thickness, are typically made of materials like stainless steel or carbon steel, known for their resistance to deformation and corrosion. The appropriate leaf or combination of leaves is selected for measurement based on the skimmer dimension.

Principle of Thickness Gauges

The dimension value is determined by the total thickness of the leaves, which are cleanly lubricated and smoothly inserted into the gap. To verify the accuracy, a leaf 0.01mm thicker than the total thickness is combined with the existing leaves to ensure it cannot be inserted into the skimmer. Caution is advised to avoid forcing the gauge into the gap. Leaf tip shapes come in two types: A-type with a circular tip and B-type with a pointed tip and rounded edge. Leaf thicknesses range from 0.01mm to 3.00mm, with lengths of 75mm, 100mm, or 150mm and a width of 12.7mm. These gauges are available in various leaf thickness combinations and are chosen based on specific requirements. It’s crucial to ensure that the leaves are free from dirt, rust, or scratches before use.

Features of Thickness Gauges

The main feature of a thickness gauge is its ability to measure narrow spaces that cannot be gauged with calipers by overlapping precisely controlled thin plates. A common application is the clearance adjustment between engine camshafts and tappets. Although there are multiple methods for measuring this clearance, analog thickness gauges are still employed in the final check process of modern engines, proving their reliability and value.