What Is a Cam?

A cam is a mechanical component designed to change the type and direction of motion. It achieves this by transmitting motion to a driven section via a contactor. For instance, the rotational motion of a circular cam can be transformed into the vertical movement of a rod-shaped driven section. Known for its simple structure, a cam offers a long service life and requires low maintenance. It is also efficient and minimizes force transmission to other parts. Cams come in various shapes and sizes, each suited for specific applications.

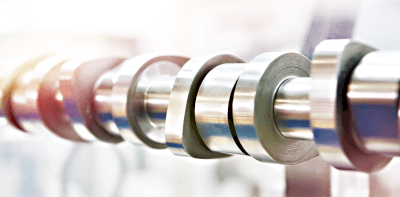

Uses of Cams

Cams are widely used in machinery and devices where a change in motion direction is needed, such as in an engine exhaust valve. In gasoline-powered vehicles, cams facilitate the smooth expulsion of exhaust gases. They transform the rotational motion of the engine into the reciprocating motion of valves, controlling the opening and closing of the valves in a timely manner.

Principles of Cams

Cams, which come in various shapes, efficiently change the motion direction. The two primary types are flat cams and three-dimensional cams.

- Flat cams, such as straight plate cams and rotating plate cams, use a simple, flat structure. Straight plate cams transfer reciprocating motion to the driven section via a contoured surface, while rotating plate cams use an irregularly shaped plate to create vertical movement in the driven node.

- Three-dimensional cams, including cylindrical, spherical, and swash plate cams, have more complex structures. These cams use grooves or inclined surfaces to enable complex motion changes in the driven section.

Designing Cams

Designing cams involves selecting the appropriate type and mechanism. Key considerations include the cam type (plane or three-dimensional), the kind of driven installation (linear or oscillating), and the details of the output motion. Creating a timing diagram and considering factors like pressure angle and lever length are crucial. The pressure angle influences the load on the contact surface, and the cam’s diameter is determined based on the maximum pressure angle. Calculations for pressure angle, radius of curvature, and other parameters ensure the cam’s shape is optimal for its function. Finally, the design must account for surface pressure, mechanical strength, rolling contact fatigue life, and rigidity.

Confirmatory Cams

Positive-acting cams ensure reliable transmission of motion to the driven section. High-speed rotation may hinder the driven section from following the cam’s movement, so a spring is often used for constraint. Examples of positive cams include frontal, cylindrical, tapered, and spherical cams.