What Is a Retaining Ring?

A retaining ring, also known as a snap ring, circlip, or retaining ring, is a metal component used to secure a shaft and a shaft-through-hole component in position.

It is designed to fit into a machined groove on a shaft or hole and holds the attached part securely in place. The portion of the retaining ring that protrudes from the groove makes contact with the mating part, ensuring it stays fixed.

Uses of Retaining Rings

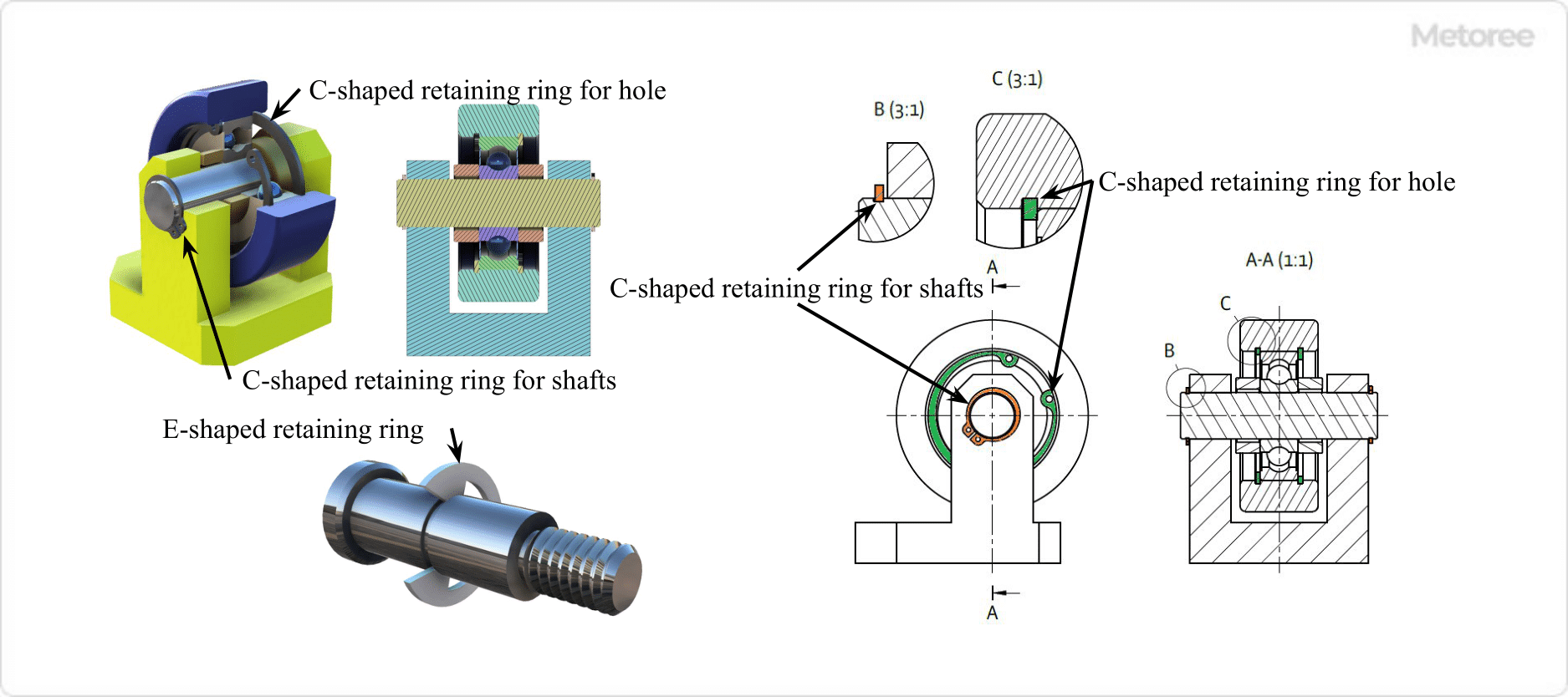

Figure 1. Example of retaining ring use

Retaining rings are commonly used in machinery to fasten parts like bearings or gears to shafts. They are available in both internal and external varieties for different applications. The selection of the ring’s shape and type depends on the fastening method and the restraining force required. Proper groove dimensions, according to JIS standards or manufacturer specifications, are necessary for installation.

Principle of Retaining Rings

Retaining rings are installed in a groove machined on the shaft or hole. The ring secures adjacent parts by fitting snugly into the groove, with its plate-width portion holding the part in place. See Figure 1 for a visual representation.

The groove dimensions are designed to accommodate the ring’s size. Special tools are often used to fit the ring into the groove properly. Once installed, the ring presses against the groove’s bottom to stay secure.

Types of Retaining Rings

1. Classification by Installation Direction

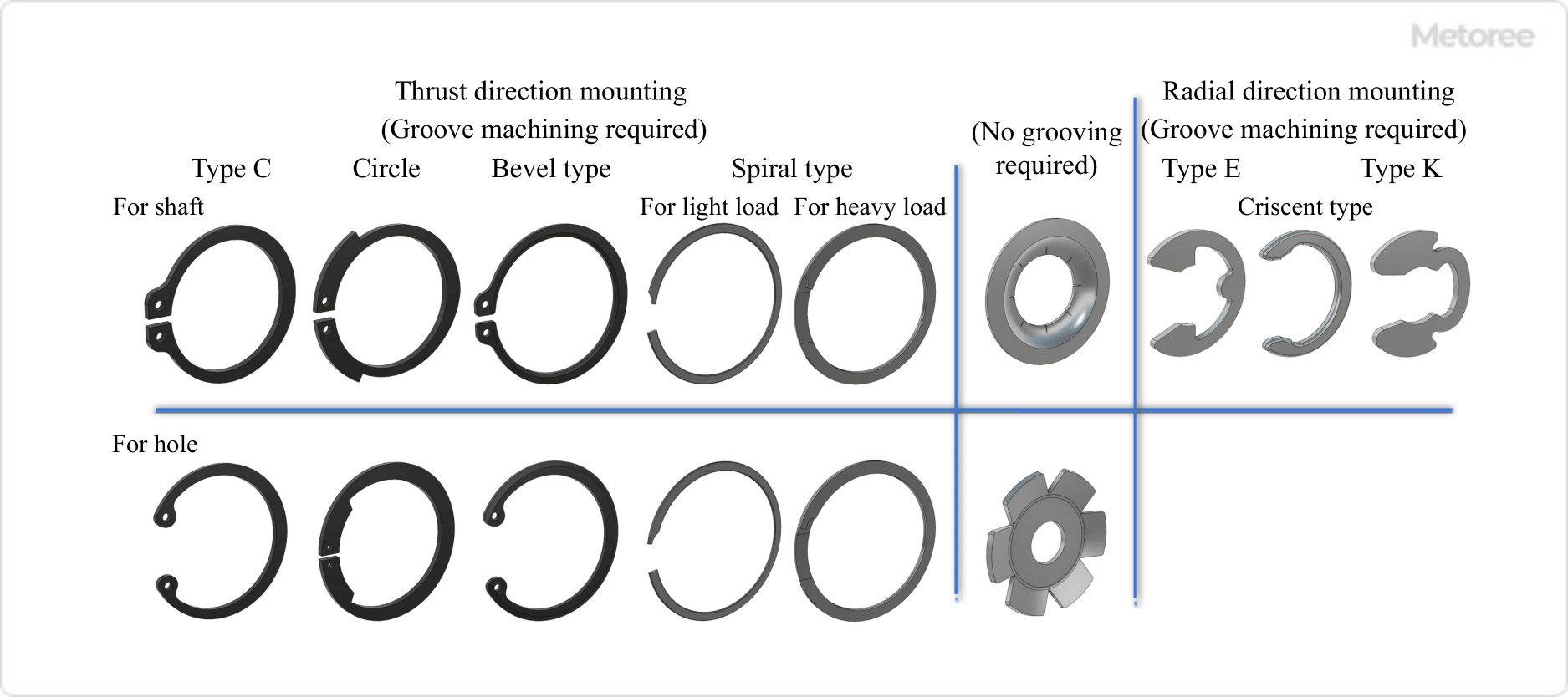

Figure 2. Mounting orientation of the retaining ring

Retaining rings are categorized based on their installation direction, with specific types for thrust direction mounting and radial mounting, each requiring groove machining.

2. Classification by Shape

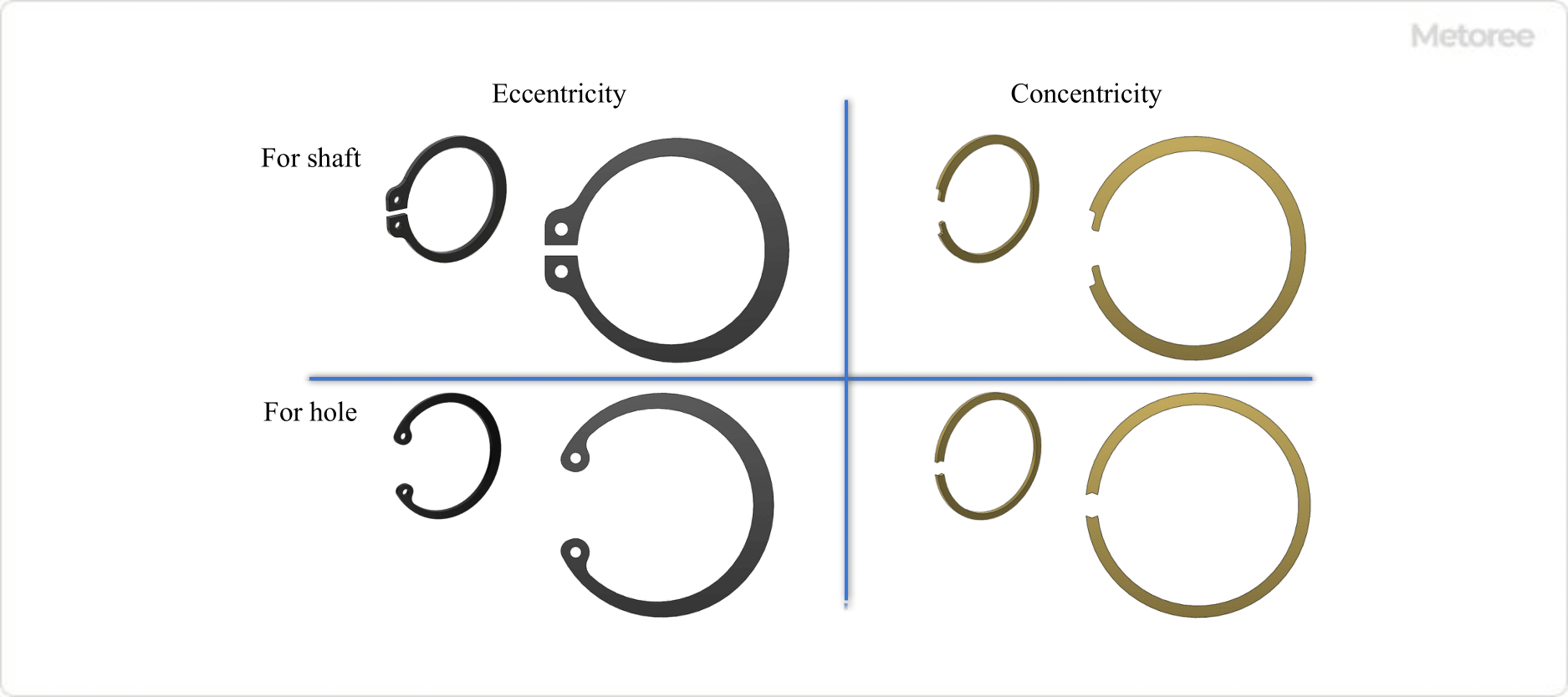

Figure 3. Shape of the retaining ring

Retaining rings also vary in shape, including eccentric and concentric types, each with distinct characteristics and applications.

Other Information About Retaining Rings

1. Material and Surface Treatment of Retaining Rings

Retaining rings are commonly made from carbon steel, hard steel wire rods, or stainless steel strips. Surface treatments like phosphate coating or hexavalent chromium coating are applied for enhanced durability and corrosion resistance.

2. Retaining Ring Standards

- JIS B 2804 Retaining rings

- ANSI/ASME B18.27 Tapered and Reduced Cross-Section Retaining Rings (Inch Series)

- ANSI/ASME B27.7 General purpose tapered and reduced cross-section retaining rings, Metric

3. Tools for Retaining Rings

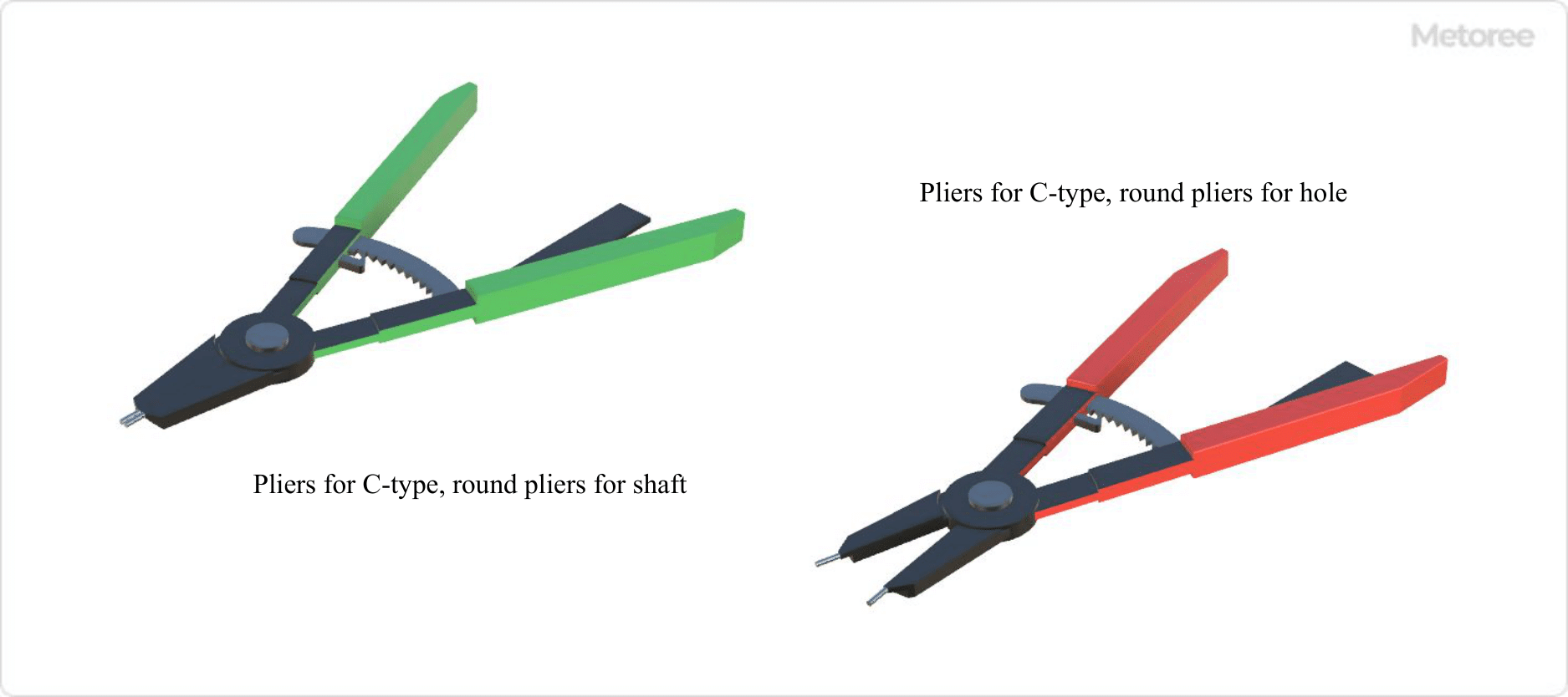

Figure 4. Pliers for retaining ring

Special pliers are used for installing and removing certain types of retaining rings, such as C- and round-shaped rings. Spiral rings can be installed and removed without special tools.