What Is a Numerically Controlled (NC) Lathe?

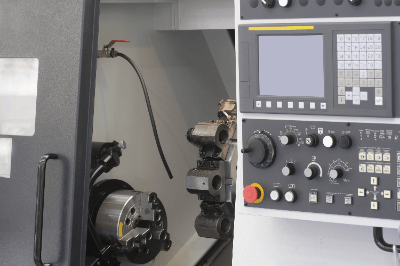

A numerically controlled (NC) lathe is a computer-controlled machine for cutting and processing materials, including metal and plastic, offering high precision and minimizing operator error.

Uses of Numerically Controlled (NC) Lathes

NC lathes are essential in metalworking, automotive, medical devices, and general manufacturing, used for precision parts like cylinder heads, crankshafts, artificial joints, and electronic components.

Principle of Numerically Controlled (NC) Lathes

The NC lathe comprises a lathe section, a computer-controlled section, and an operation section. It includes a motor, spindle, spindle, chuck, and vise, with sensors for precision. Oil reduces friction during cutting.

Types of Numerically Controlled (NC) Lathes

Diverse NC lathe types cater to different manufacturing needs.

1. 2-Spindle Numerically Controlled (NC) Lathe

A two-axis NC lathe that can cut multiple parts simultaneously, ideal for efficient machining.

2. Compact Numerically Controlled (NC) Lathe

Smaller in size, these lathes are suitable for machining fine parts in limited spaces. Desktop models are also used for education and small-scale production.