What Is Milling Machinery?

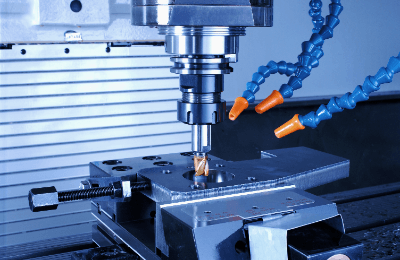

Milling machinery is primarily used to cut hard materials such as metal into desired shapes. In terms of shaping materials, milling machinery is similar to a lathe, but with a key distinction: while a lathe rotates the material, milling machinery employs a rotating blade or drill. This fundamental difference sets milling machinery apart from lathes.

Uses of Milling Machinery

Milling machinery serves as a machine tool for shaping materials into desired forms. Its primary function is material removal, allowing it to sculpt shapes similar to those of sculptures. Additionally, by attaching a drill or other tool, milling machinery can be used for drilling holes or performing various operations at specific locations. The utility of milling machinery varies based on the range of motion of the main spindle to which the cutting tool is attached. General milling machinery is categorized as three-dimensional milling machinery and can be employed for machining three-dimensional shapes from surfaces or radiused surfaces. Milling machinery is highly versatile and efficient, capable of handling both external shaping and drilling operations in a single machine.

Principles of Milling Machinery

This section outlines the operational principles and types of milling machinery. In milling machinery, the material is securely fixed on the table and remains stationary. Instead, the spindle, with the cutting tool attached, rotates and moves in three planes (X, Y, and Z) to shape a three-dimensional object. There are two primary types of milling machinery: “Bed Type” and “Knee Type.” Here are the specific movements for each:

- Bed Type: In the bed type, the spindle can move vertically in the Z direction, while the table moves in the XY plane to manipulate the material. The bed type is particularly advantageous for mass production.

- Knee Type: In the knee type, the table shifts the material both vertically and horizontally without moving the spindle. It is considered the most versatile type of milling machinery. The role of milling machinery varies based on the installed cutting tool. Here are some common examples:

- Front Facing Milling Machine: This is the most common milling tool used for cutting flat surfaces. It offers high cutting capacity and can be reused by replacing the cutting edge.

- Side Milling Cutter: A milling tool with cutting edges on the outside, primarily used for cutting side surfaces. Also known as a side cutter.

- End Mill: A versatile cutting tool with functions similar to a drill, capable of perimeter machining, drilling, grooving, and more. It is widely used for various machining operations.

Milling Machinery Tools

Milling machinery can perform a variety of machining operations by changing the spindle tool.

The most common type of tool used with milling machinery is the milling cutter for flat surface machining. These cutters come in various sizes and are suitable for roughing. For finishing operations, the appropriate cutter is selected based on the area to be machined and the amount of material to be removed at once.

In addition to milling cutters, end mills are frequently used tools capable of side machining, grooving, and drilling in thin plates. End mills have cutting edges on the side and bottom surfaces, allowing them to machine the side and flat surfaces of materials, making them ideal for step and groove machining.

Various types of end mills are available, including square end mills with flat bottoms, radius end mills with an R-shaped bottom cutting edge for increased rigidity, and ball end mills with spherical cutting edges. Each type has its own specialties, so selecting the appropriate end mill based on the machining method is essential.

Milling machinery can also be used for drilling, similar to a drilling machine. Various tools can be used, ranging from pre-drilling drills to reamers and boring cutters for high-precision holes, as well as taps for threading.

Features of Milling Machinery

In contrast to lathes, milling machinery stands out due to the rotation of the blade for cutting and its diverse types, including vertical and horizontal orientations, general-purpose milling machinery, and NC milling machinery. Let us explore each type in detail:

Vertical milling machinery has its spindle mounted perpendicularly to the ground and is the most widely used type due to its high workability.

Horizontal milling machinery has its spindle mounted parallel to the ground and is suitable for grooving and cutting. It is characterized by the fact that chips produced during machining fall naturally due to gravity, preventing chip accumulation on the workpiece. However, it’s essential to remain vigilant as it’s easy to mistake the XYZ direction when transitioning from the vertical type.

General-purpose milling machinery is manually operated, allowing operators to control dimensions by hand using handles. It is well-suited for crafting unique, one-of-a-kind pieces.